3D Laser HMI

H.M.I.

New H.M.I. for 3D laser fiber machines

User friendly

Intuitive

Fast learning

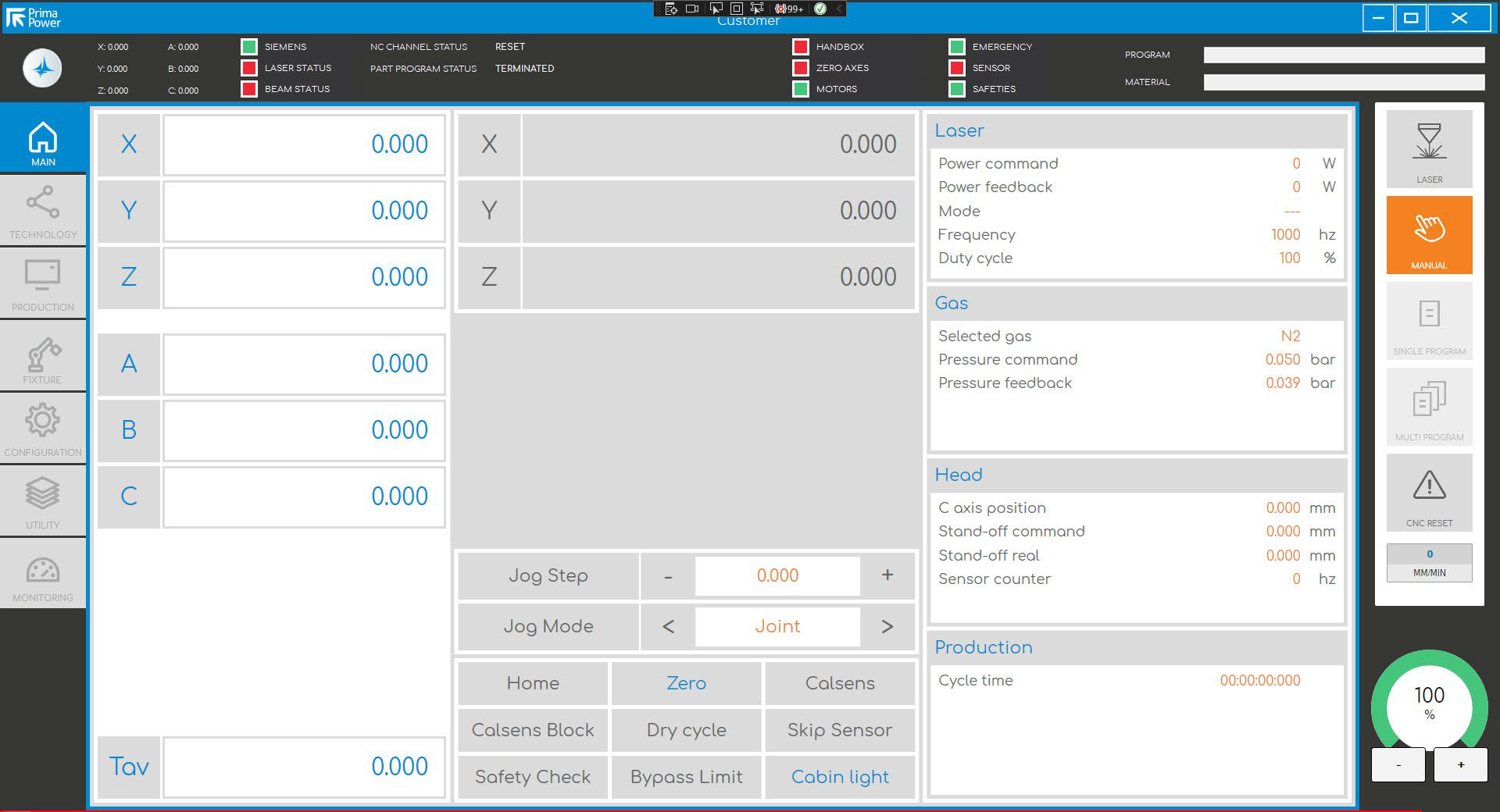

The new Prima Power Human Machine Interface for 3D laser machines, available for Laser Next 1530 and Laser Next 2130 starting from machine version 5, has been designed to meet the needs of all types of users, the new 3D Laser HMI (based on Tulus architecture) can save operators up to 15% of time in performing daily tasks.

Fast and easy fault analysis to enable any operator to recover quickly from any situation.

Different functions depending on user's level:

Entry level operator

- Intuitive

- User friendly

- Quick learning curve

Skilled operator

- Relevant machine information always available

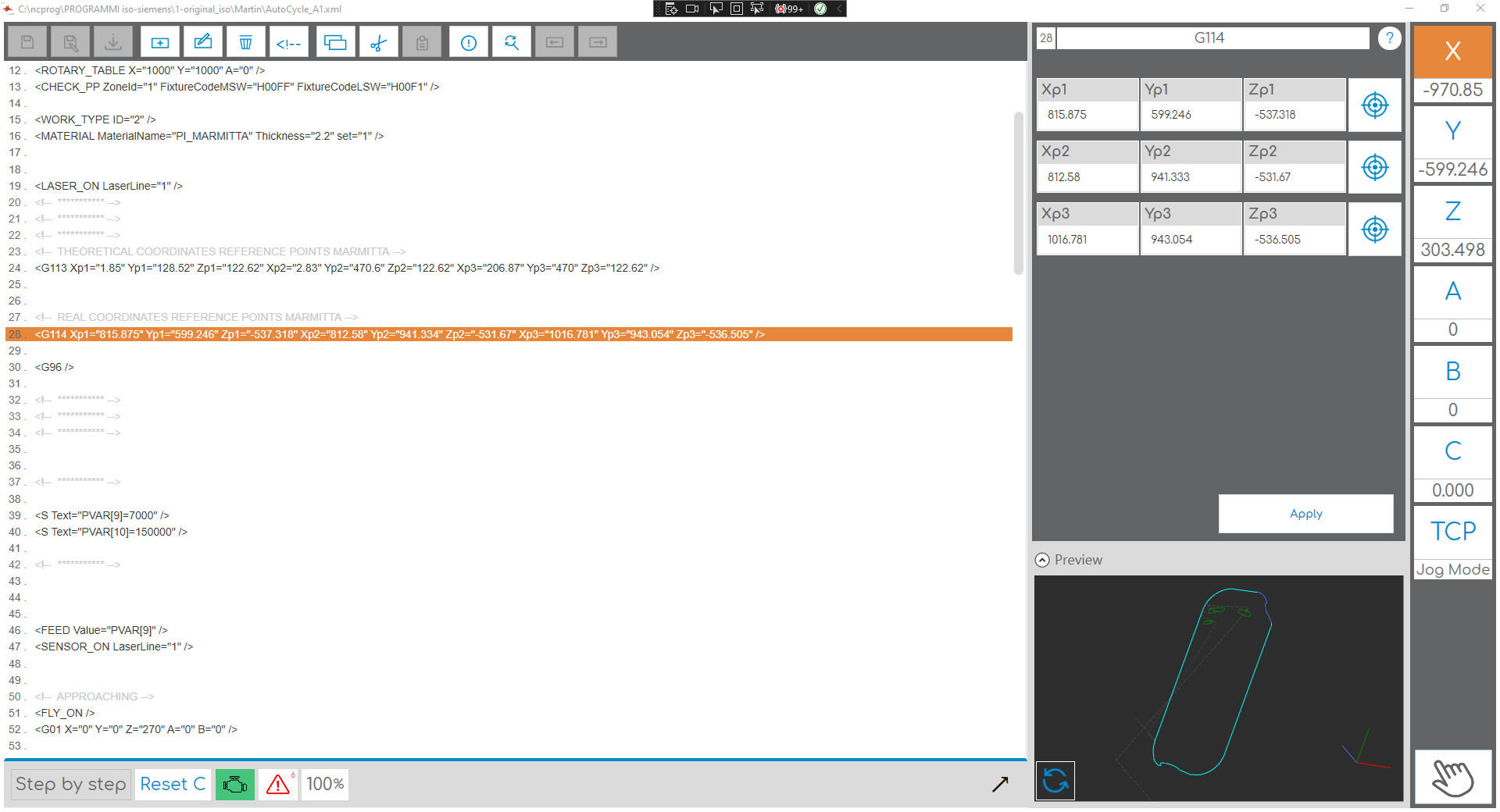

- Better program editing experience with program editor

Plant manager

- Compatibility with Tulus Office

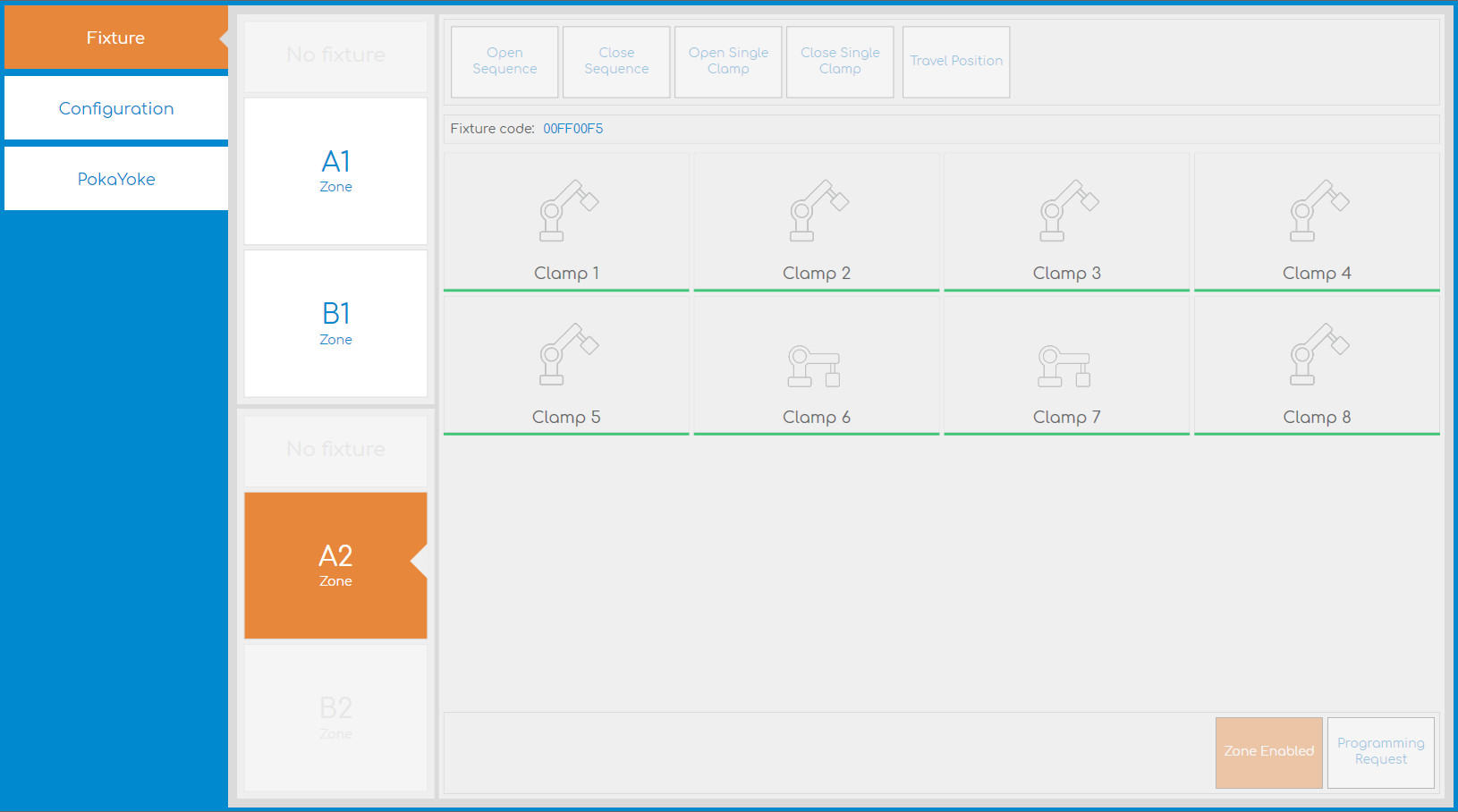

The software is a comprehensive and flexible program created designed to control and operate the machine's production cycle. It provides an information system with alarm code explanations, user manuals, dynamic work queue function as well as fast file transfer. All these support the operator in several ways facilitating self-learning possibilities, giving recovery instructions and simple access to electronic manuals, spare part parts manuals etc.

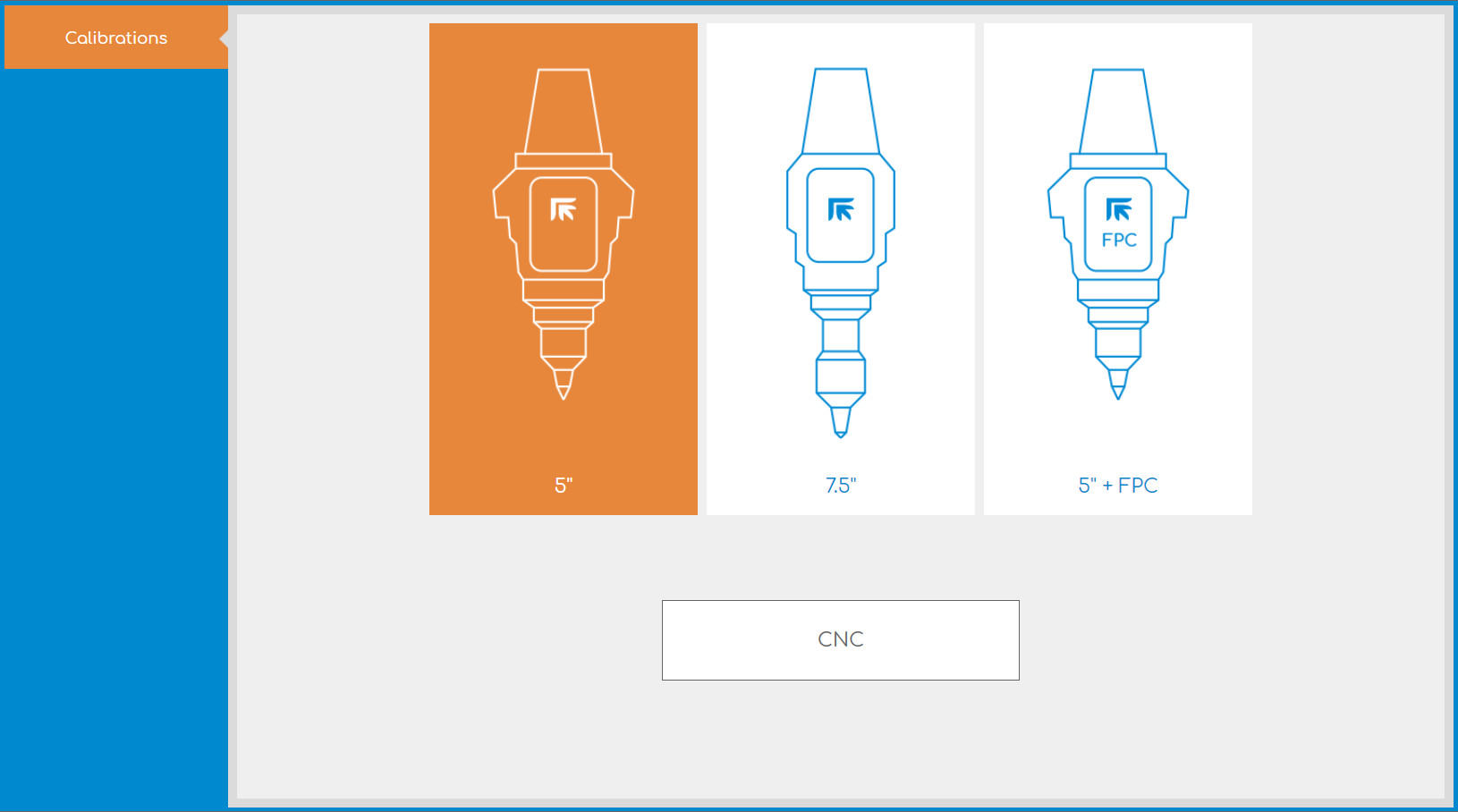

The HMI also enables the creation, manipulation, or loading of the set of parameters that contribute to the machine's operation via software. A database for main technological applications is available directly on-board.

In addition, the system offers to the operator the possibility to customize cutting parameters (e.g. feed rate, cutting gas pressure and so on) online, directly on the touch screen panel, even during the laser process.

Technologies connexes

Secteurs connexes

Take a look at the other products and choose the best solution

Cellule Tulus

H.M.I.

Famille de logiciels intégrés et évolutifs pour la gestion centralisée de la fabrication.

Tul-Robot

H.M.I.

L'interface opérateur qui permet de gérer le système et les programmes pièces pendant la phase de production.

Surveillance visuelle de Tulus

H.M.I.

Application web pour les opérateurs de machines qui apporte une transparence de l'information sur l'état actuel de la ligne de fabrication

Optia

H.M.I.

OPTIA permet une simplification extraordinaire du processus de récupération des déchets de tôle.

Tulus Storage

H.M.I.