For a company that values environmental awareness and energy efficiency, finding technological solutions able to meet its efficiency and sustainability goals is crucial. That is why Pipemodul Oy, a family business located in Mikkeli, Finland, has chosen Prima Power’s servo-electric eP 1030 press brake, which provides versatile production opportunities while consuming less power and requiring less maintenance.

THE STORY OF PIPEMODUL: FROM IDEA TO SUCCESS

Pipemodul Oy was founded by Vesa Partanen in 1999, after developing an industrially prefabricated building technology box. The core idea of the building technology enclosure was to make plumbing renovations in real estate easier, cleaner, and faster. The purpose was also to get more industrial thinking into the field. This is how the company’s flagship, the openable pipemodul® system, was created. In addition to renovation projects, the company’s products are also employed in new building constructions.

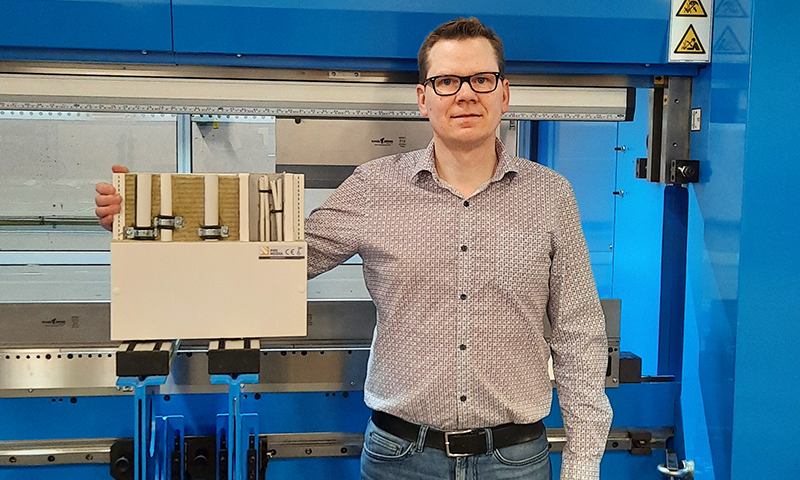

Today, Pipemodul is specialized in the design and industrial production of prefabricated pipelines and cable boxes and employs around twenty people in the field. Vesa Partanen’s son, Asko Partanen, has been the company’s CEO since 2008. The Pipemodul solution has already been used for more than 20 years in over 4,000 locations, both in residential and public buildings mainly located in Finland and Sweden.

PRIORITIZING SUSTAINABILITY WITH PRIMA POWER’S PRESS BRAKE

Pipemodul’s new investment, Prima Power’s servo-electric eP 1030 press brake, was put into operation at the beginning of 2023.

“We chose Prima Power’s press brake, because we felt it was good for our needs both in terms of technology and other features”, says Partanen. “Service availability was also an important criterion in the procurement. The people at Prima Power are professional and motivated, and we always get fast and good service from them.”

ENVIRONMENTAL AND ENERGY ISSUES ARE IMPORTANT TO PIPEMODUL

The company’s products have a long life cycle and the amount of waste generated at the installation site is very small. These values were also reflected in the machine selection.

Prima Power’s servo-electric press brakes are known for their sustainability, efficiency, and high productivity. They offer versatile production possibilities with lower power consumption and maintenance needs. Furthermore, they eliminate the need for oil purchase and processing.

In addition, the easy programming and high accuracy help to minimize material waste during the production process. Electric servo drive combines productivity, precision, flexibility, and reliability while also considering environmental aspects.

“Ecological factors, such as energy efficiency, played a significant role in the machinery investment decision”, explains Sami Lehto, Pipemodul’s technical manager. “The press brake is easy to operate, and has fast working movements and quick tool change. Users have reported positive experiences and high satisfaction with the new machine”.

Ecological factors, such as energy efficiency, played a significant role in the machinery investment decision.