De Castelli - The art of metal mastery

An interview with Francesca Celato and Filippo Pisan, De Castelli marketing manager and De Castelli artistic director, head of the R&D department

De Castelli, rooted in Treviso, Italy, has been exploring metal’s expressive potential across four generations, blending artisanal techniques with industrial methods. In its beautiful creations, metal emerges as a protagonist: a medium rich with aesthetic possibilities. With prestigious partnerships and awards, like the Archiproducts Design Awards 2023 for the Folio table, De Castelli showcases its commitment to innovation and ongoing research.

DE CASTELLI, A BRAND SYNONYMOUS WITH THE CELATO FAMILY’S RICH HERITAGE. COULD YOU SHARE MORE ABOUT THE COMPANY’S JOURNEY?

Since its inception, De Castelli has led the way in metal craftsmanship, dedicated to unlocking its full potential. Established officially in 2003, the company’s roots are deeply intertwined with the enduring legacy of the Celato family, its founders, whose metalworking heritage traces back to the late 19th century. With strong ties to the Veneto region, they initially specialized in agricultural tools, before expanding into copper and brass homeware and distillation equipment. Guided by CEO Albino Celato in the mid-1990s, De Castelli embarked on a period of significant growth, investing in cutting-edge metalworking machinery. Today, the company blends traditional craftsmanship with modern technology, utilizing CNC machines, lasers, bending systems, and other equipment to craft unique products.

HOW DOES DE CASTELLI SET ITSELF APART IN THE MARKET?

Primarily, we prioritize staying contemporary. De Castelli consistently engages with designers and architects to anticipate trends. Extensive collaborations expand our perspectives on metal, shaping our product range. Equally significant is the role of research: despite our deep expertise, working with a single material prompts constant exploration for new ideas. Our work embodies a fusion of art, community, research, and traditional techniques reimagined for contemporary contexts.

WHAT QUALITIES OR FEATURES DO CUSTOMERS TYPICALLY SEEK WHEN CONSIDERING DE CASTELLI PRODUCTS?

Our main audience includes architects, and De Castelli showcases its capabilities and expertise while highlighting the vast potential of metal. Our clients value craftsmanship and each piece’s uniqueness. We merge artisanal techniques with an industrial mindset: design is industrial, but production maintains an artisanal touch. Each piece carries subtle variations, reflecting our craftsmanship and unique identity, almost elevating them to artworks.

WHAT ARE THE KEY TECHNICAL CHALLENGES IN METALWORKING AND WHAT EXPRESSIVE POTENTIALS DOES METAL OFFER IN THE FIELD OF DESIGN?

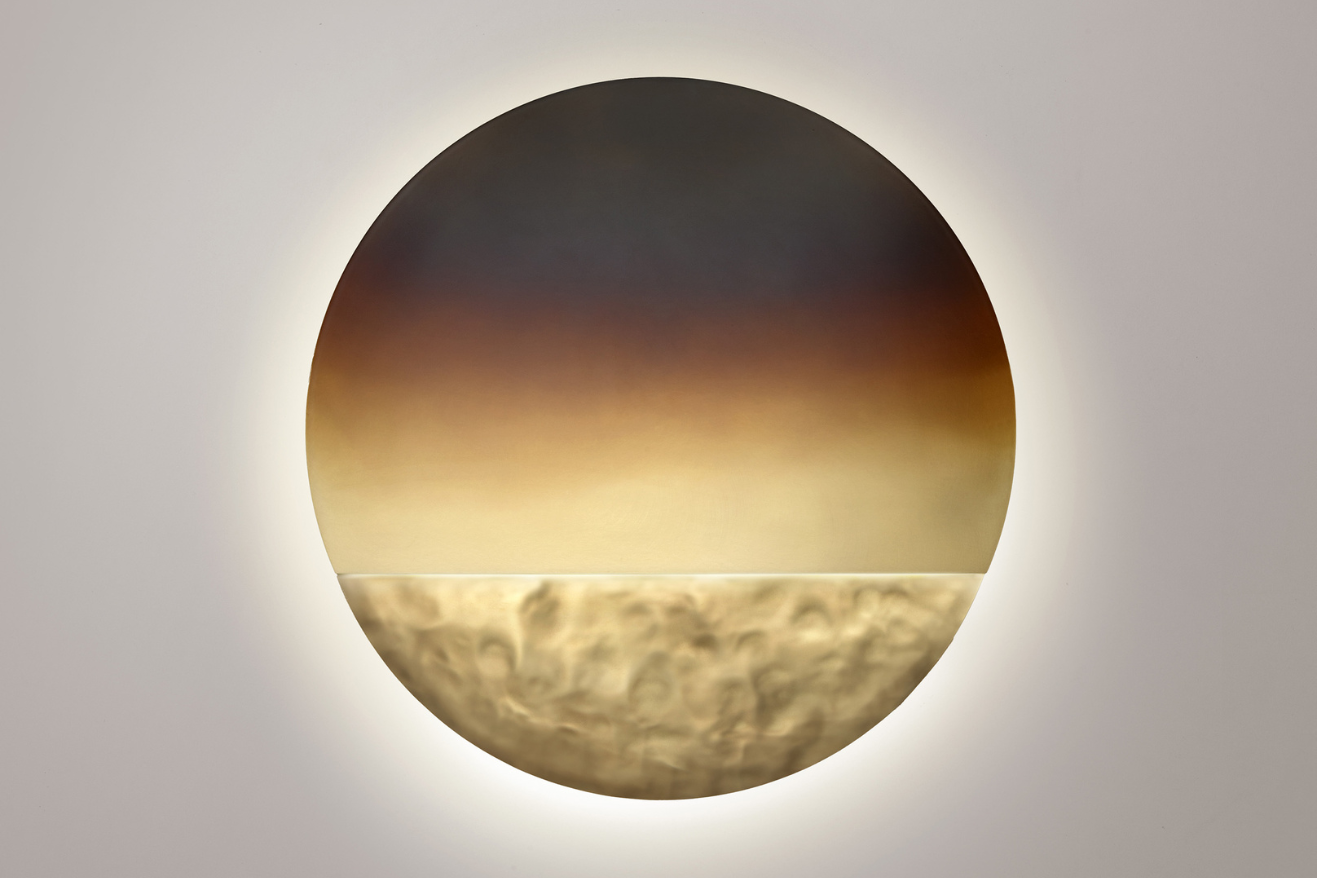

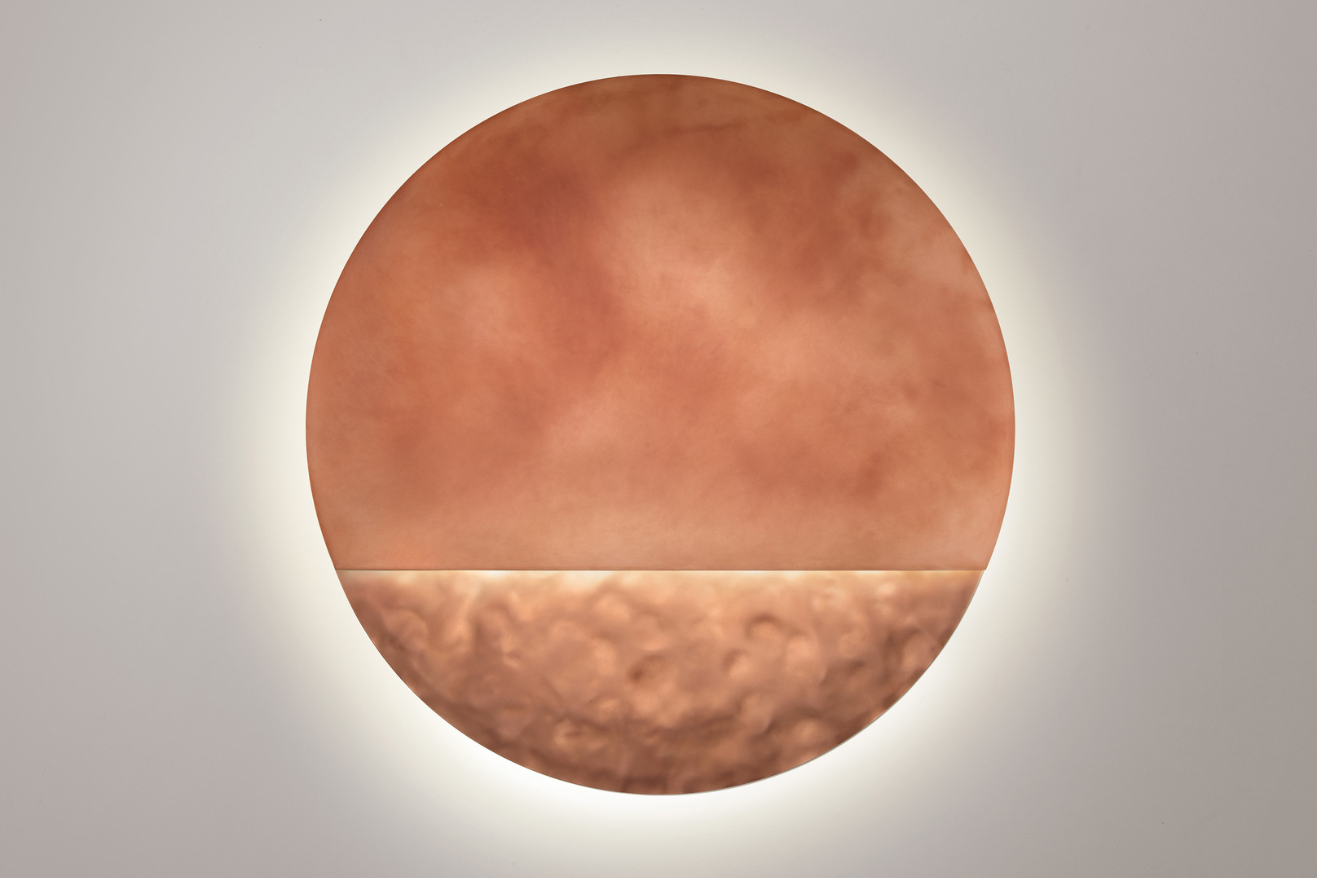

Metal, valued for its technical properties like rigidity, strength, and ability to shape intricate forms, has long been used in design and architecture. Once seen as merely structural, we opted to

highlight its aesthetic potential through a play of contrasts. Despite its weight, we infuse our creations with a sense of lightness. Often perceived as cold, we’ve integrated metal into domestic settings, evoking warmth and comfort through oxidation. Material is central to our work, going beyond function. Rather than hide it, we accentuate its defining features, like oxidation. We even accelerate this process to achieve preoxidized finishes, a testament to our reverence for the material.

WHAT TYPES OF METALS DO YOU WORK WITH, AND WHAT METALWORKING TECHNIQUES DO YOU UTILIZE?

Our main focus is on premium metals like copper, brass, and steel, sourced in sheet form to match our processing methods. These metals offer versatility in size and thickness and align with our array of technologies. We start with sheet metal, going through laser cutting, bending, rolling, shaping, padding, hand-hammering, and welding, before oxidation.

WHAT ARE THE CURRENT TRENDS IN YOUR INDUSTRY?

In recent years, there’s been a notable convergence between design and art, driving demand for unique, customizable products. Meeting specific client needs sets products apart, a level of customization not achievable with mass production. Moreover, there’s a rising focus on sustainability in materials and manufacturing, aimed at reducing environmental impact and promoting reintegration into the production cycle.

HOW DOES DE CASTELLI ENSURE SUSTAINABILITY IN ITS PRODUCTION CYCLE?

De Castelli is deeply committed to sustainability throughout its production process. First of all, our products are designed for longevity, reducing the need for replacements. We manage waste meticulously by segregating material scraps, and recycling them in a closed-loop syste m, conserving resources. Our advanced water management system efficiently reuses water in oxidation processes, minimizing overall consumption. We’re also transitioning to fully recyclable paper packaging to reduce plastic use, aligning with our sustainability goals while delivering quality products.

Metal has long been used in design and architecture as a mere structural element, we have chosen to highlight its aesthetic potential.