Flexible Manufacturing Systems

Família de produtos

Uma gama completa e modulas de soluções para gestão de estágios de trabalho, fluxo de informação e manuseio de material. Produtividade única baseada na experiência ímpar da Prima Power.

Saiba como a tecnologia de sistemas da Prima Power pode ajudar você a otimizar sua produção

Escolha o sistema perfeito para você

A tecnologia da Prima Power no Sistema Flexível de Manufatura automatiza o material e os sistemas de informação de uma unidade e combina estágios individuais de manufatura em um único processo flexível. Com tecnologia da Prima Power no Sistema Flexível de Manufatura, o fabricante alcança eficiência superior de custotanto em produções em série como na manufatura de pequenos lotes.

Saiba mais sobre nosso portfólio de produtos de Sistemas Flexíveis de Manufatura

Escolha a automação perfeita de Armazenamento para você

Soluções flexíveis de armazenamento para automatizar o fluxo de materiais, disponibilizando diferentes materiais quando necessário e sem atrasos, enquanto também serve como armazenamento intermediário para componentes prontos ou como bufferes. A partir de soluções únicas em torre a galpões totalmente automatizados, a Prima Power oferece a solução adequada para cada aplicação e tamanho de planta.

Saiba mais sobre nosso portfólio de produtos de soluções de armazenamento

Família de produtos

Indústrias relacionadas

Escolha o Sistema perfeito para si

LBB

FLEXIBLE MANUFACTURING SYSTEMS

Lights-out production capacity with outstanding flexibility

PSBB

SISTEMAS DE FABRICO FLEXÍVEIS

Um sistema de manufaturação flexível

Night Train FMS®

SISTEMAS DE FABRICO FLEXÍVEIS

Solução de armazenamento de tecnologia líder em sistemas de manufaturação flexíveis automatizados

Armazenamento de carregamento rápido

ARMAZENAMENTO

Uma solução rápida e económica para fluxo de materiais

Dispositivo de carregamento rápido

ARMAZENAMENTO

Para carregamento rápido de material em tempo oculto

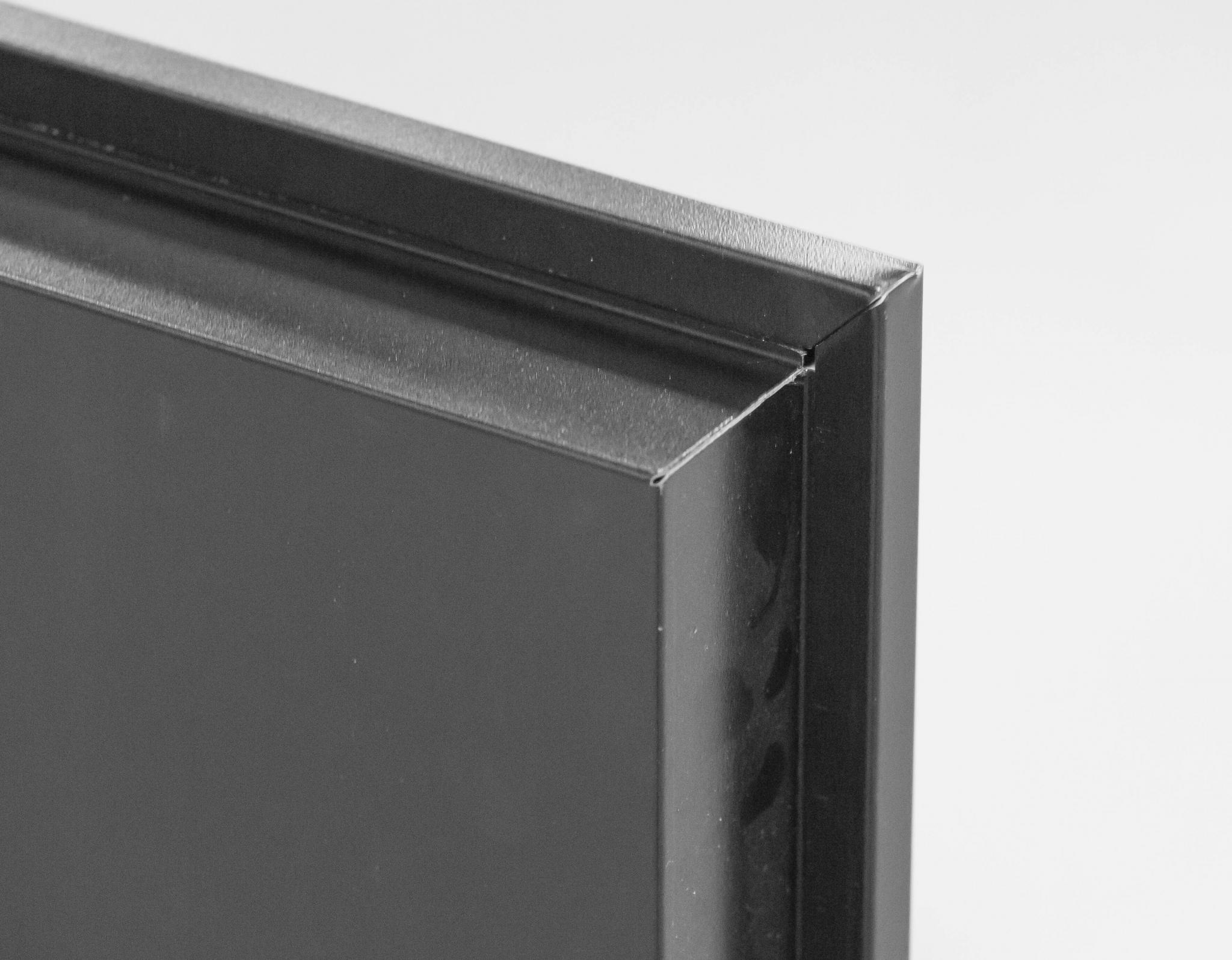

Torre Combo

ARMAZENAMENTO

Fluxo de material fluente e uma grande capacidade de armazenamento

Torre Combo Laser

ARMAZENAMENTO

O módulo chave para automatizar o fluxo de material com máquinas a laser 2D

PunchBend

SISTEMAS DE FABRICO FLEXÍVEIS

Do material cortado ao tamanho de componentes prontos a dobrar

HISTÓRIAS DE SUCESSO

Saiba como a tecnologia Systems da Prima Power contribuiu para o sucesso de uma empresa

JST Power Equipment, having the right facilities to say ‘yes’ to clients is priceless.

Switchgear lineups are engineered-to-order products with a lot of variation among jobs, including fabricated sheet metal parts. Enabling the new JST Power Equipment switchgear-manufacturing plant to excel at taking on low-volume production: an automated punch-shear combination machine.

Gi.Metal, ready for a batch of productivity

If Italian cuisine is one of the most famous and renowned in the world, then this is definitely thanks to chefs who have exported the recipe, but those who produce kitchen utensils also play a very important role. Such is the case for Gi.Metal, who specialises in the manufacture of pizzeria equipment, which use prima power lasers in the cutting process.

Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

Vision: that all-human drive towards evolution

Discover Brink and Prima Power partnership, a success story made of human connections.

Order and efficiency drive productivity, from first cut to finished product

Astra was founded just short of thirty years ago as the result of an innovative instinct which proved successful in just a few years: that stainless steel would become the technological material of the future.

Automation as a Competitive Edge

Thanks to integrating a Prima Power fully-automatic laser cutting system, consisting of a 6 kW Platino Fiber 2.0 laser cutting machine, along with a Night Train automated warehouse, Carpenteria Metallica Depedri has been able to increase productivity by 30%.

New investments create productivity at Halton’s Kausala factory

Halton Group is the world's leading provider of indoor air solutions. Indoor air solutions are divided into four segments: Marine, Health, Foodservice, and Buildings

Prima Power PSBB Helps Power Generation Giant Build Flexible Manufacturing System

Headquartered in Spain, with 8 production centers, 13 subsidiaries worldwide, and a global network made up of 1,000 employees who work closely with more than 130 distributors around the world, HIMOINSA, part of the Yanmar Group, is one of the top global giants that designs, manufactures and distributes power generation equipment.

A look at the technology behind turnkey organic poultry plants

SKA srl manufactures poultry systems for organic free-range farming with high levels of product customisation by taking advantage of innovative Prima Power technology.

Steelcomp invests in a new factory with advanced automation

Steelcomp Oy will continue its strong production development work in its operations in Kauhava, Finland. With a newly completed plant extending over more than 5,000 square meters and extensive investments in Prima Power production automation, the company is on the road to strong growth for years to come.