Guida Srl - Elevating production with 2D Laser Cutting technology

An italian family business ehnances efficiency partnering with Prima Power: the Guida Srl experience

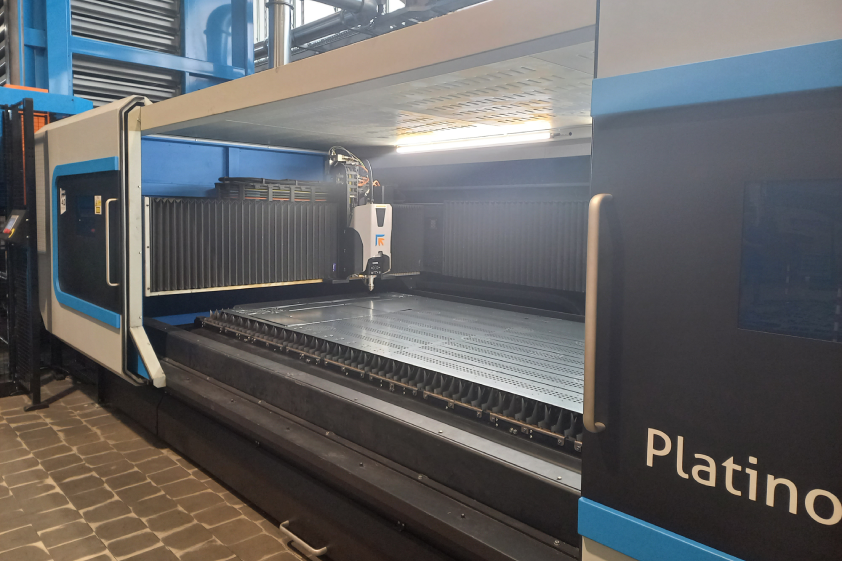

WITH A PARTNERSHIP SPANNING SINCE 1997, GUIDA SRL HAS RECENTLY INTEGRATED PRIMA POWER’S PLATINO LINEAR 1530 LASER MACHINE, DOUBLING CUTTING SPEED AND CUTTING ENERGY COSTS BY 50%.

What advantages can a laser cutting machine provide? Simone and Luca Guida, leading their family business Guida Srl, longtime clients of Prima Power, share their insights. Their latest investment is in a fiber laser cutting machine: the 8kW Platino Linear 1530, Prima Power’s newest addition to the market.

Established in 1987 in Turin, Guida Srl was founded by Francesco Guida, venturing into the realm of sheet metal processing. Today, Francesco collaborates with his sons, Simone and Luca, who are assuming leadership roles within the family enterprise. “We are a small artisanal business,” says Simone Guida, “my father started it with three employees and a couple of machines; today we’re a team of 15, using various machines for laser cutting, bending and welding. Our work is divided into departments: 2D laser cutting, where we have a CO2 laser machine, a fiber laser and one for tube laser cutting; bending, with 6 press brakes and three dedicated staff members; and then welding, assembly and painting.”

For 27 years, Prima Power has been integral to the journey of Guida Srl. It all began in 1997 with the acquisition of a 2.5kW CO2 Platino series laser machine, featuring automatic pallet change. “My father,” continues Simone Guida, “proudly recalls that the Platino laser we bought from Prima Power was the third one ever produced. In 2008 we upgraded to a 4kW Platino laser machine with vertical automated storage, which allowed us to expand even more.” The company recently enhanced its laser cutting capabilities with the addition of the Platino Linear 1530 fiber laser, further enhancing production capacity. “Prima Power involved us and other producers in developing this machine,” explains Simone Guida. “We provided a list of suggestions, including a 3-meter front opening, which were integrated into the design of the Platino Linear 1530. This highlights Prima Power’s responsiveness to its customers’ needs.”

BOOSTING EFFICIENCY WITH PRIMA POWER’S PLATINO LINEAR 1530

Prima Power’s Platino Linear 1530 laser cutting machine, with an 8kW fiber power source, handles 3,000x1,500 mm metal sheets with ease, all within a compact design. This machine improved the company’s production and workflow efficiency.

“Platino Linear 1530,” affirms Simone Guida, “stands out for its incredible flexibility thanks to its fully unrestricted front opening essential for swift sheet loading. To maximize productivity, we have integrated two automatic towers with 46 cassettes. This has significantly enhanced our competitiveness and opened up new market opportunities.”

Platino Linear 1530 is generally used to cut mild steel up to 20 mm in thickness, aluminum and stainless steel up to 15 mm, copper and brass up to 6 mm, for a wide range of sectors. “We specialize in the industrial sector,” explains Luca Guida, “where we build machine parts, guards, panels and cabinets. We also engage in packaging and furnishings. This diversification ensures a constant workflow without interruptions in production. With the introduction of the Platino Linear, we expect a significant boost in our production capacity, thanks to its unmatched speed and flexibility.

The machine allows us to achieve remarkable precision even with thicker materials and has substantially increased our speed: we have doubled our cutting speed compared to before”. Another significant advantage of Platino Linear is its linear motors, which reduce the need for maintenance to practically zero. “This was one of the main reasons we chose this machine,” observes Simone Guida. “The lower the maintenance a machine requires, the more we can produce.” Its energy efficiency was another determining factor. “The fiber laser,” explains Simone Guida, “only uses power while cutting, resulting in enhanced cutting performance and a simultaneous reduction in energy costs of around 50% for both electricity and gas”.

A VISION OF EXCELLENCE THROUGH ORGANIZATIONAL STRENGTH

Guida Srl looks to the future with determination, firmly observing a fundamental principal: organization. “The production landscape has changed,” remarks Simone Guida. “Whereas we once handled large-volume orders, we now encounter requests for smaller batches with varying lead times. As subcontractors, we have to be flexible and ready; this is only possible with good internal organization. We aim to instill our commitment to organization in our customers, fostering a shared dedication to excellence.”

Guida Srl’s future projects are well defined. “First and foremost,” explains Luca Guida, “we would like to remain a small business, while strengthening it through constant technological upgrades. We’re considering integrating a robotic cell and a semi-automatic panel bender from Prima Power. These days cobots (collaborative robots) allow for small batch production in a very simplified manner; before, programming a traditional robot was complicated and costly, to the point of not being sustainable for small orders. Integrating a cobot into our bending and welding departments would make us even more competitive.”

Prima Power involved us and other producers in developing this machine: we provided a list of suggestions, which were integrated into the design of the Platino Linear 1530. This highlights Prima Power’s responsiveness to its customers’ needs.