2D laser cutting technology

Laser cutting is an amazingly flexible productive technology. A wide variety of materials and thicknesses can be processed, with no limit to the shape you can obtain. Its programming is so fast that any modification can be applied at any stage of production, practically without additional cost and time. Precision is highest, cutting quality is excellent and no distortion of parts occurs. The best application of laser technology is the processing of metal materials (mild steel, stainless steel, aluminum, copper, and brass) with a thickness from 0.8 mm to 30 mm.

The productivity of this technology can be further enhanced by the wide range of modular automation solutions that can help manage the entire production cycle and the technology suites of options to adapt laser cutting to specific customer requirements.

Related industries

Choose the perfect 2D laser cutting machine for you

Platino Linear

2D LASER CUTTING MACHINE

The reliable and productive solution for cost-effective 2D laser processing

Laser Genius+

2D LASER CUTTING MACHINES

Prima Power laser machine faster, more precise, cheaper, for larger and heavier pieces.

STORIES OF EVOLUTION

Discover how Prima Power's 2D laser cutting technology has contributed to the success of a company

Vacuum Technology Inc., High-Tech manufacturer chooses Platino Fiber Laser

Laser cutting addition speeds production for a Tennessee supplier of gas-leak-testing technology while freeing waterjet cutting machines for other work. It’s an all-around win for Vacuum Technology Inc.

Gi.Metal, ready for a batch of productivity

If Italian cuisine is one of the most famous and renowned in the world, then this is definitely thanks to chefs who have exported the recipe, but those who produce kitchen utensils also play a very important role. Such is the case for Gi.Metal, who specialises in the manufacture of pizzeria equipment, which use Prima Power lasers in the cutting process.

Astra | Order and efficiency drive productivity, from first cut to finished product

Astra was founded just short of thirty years ago as the result of an innovative instinct which proved successful in just a few years: that stainless steel would become the technological material of the future.

ATP | Flexibility and precision in the manufacture of custom rack cabinets

After having chosen Prima Power as the supplier of the company's very first laser cutting machine, ATP decided to continue focusing on the quality and technology of the Italian manufacturer by also investing in a servo-electric bending machine

Carpenteria Metallica Depedri | Automation as a Competitive Edge

Thanks to integrating a Prima Power fully-automatic laser cutting system, consisting of a 6 kW Platino Fiber 2.0 laser cutting machine, along with a Night Train automated warehouse, Carpenteria Metallica Depedri has been able to increase productivity by 30%.

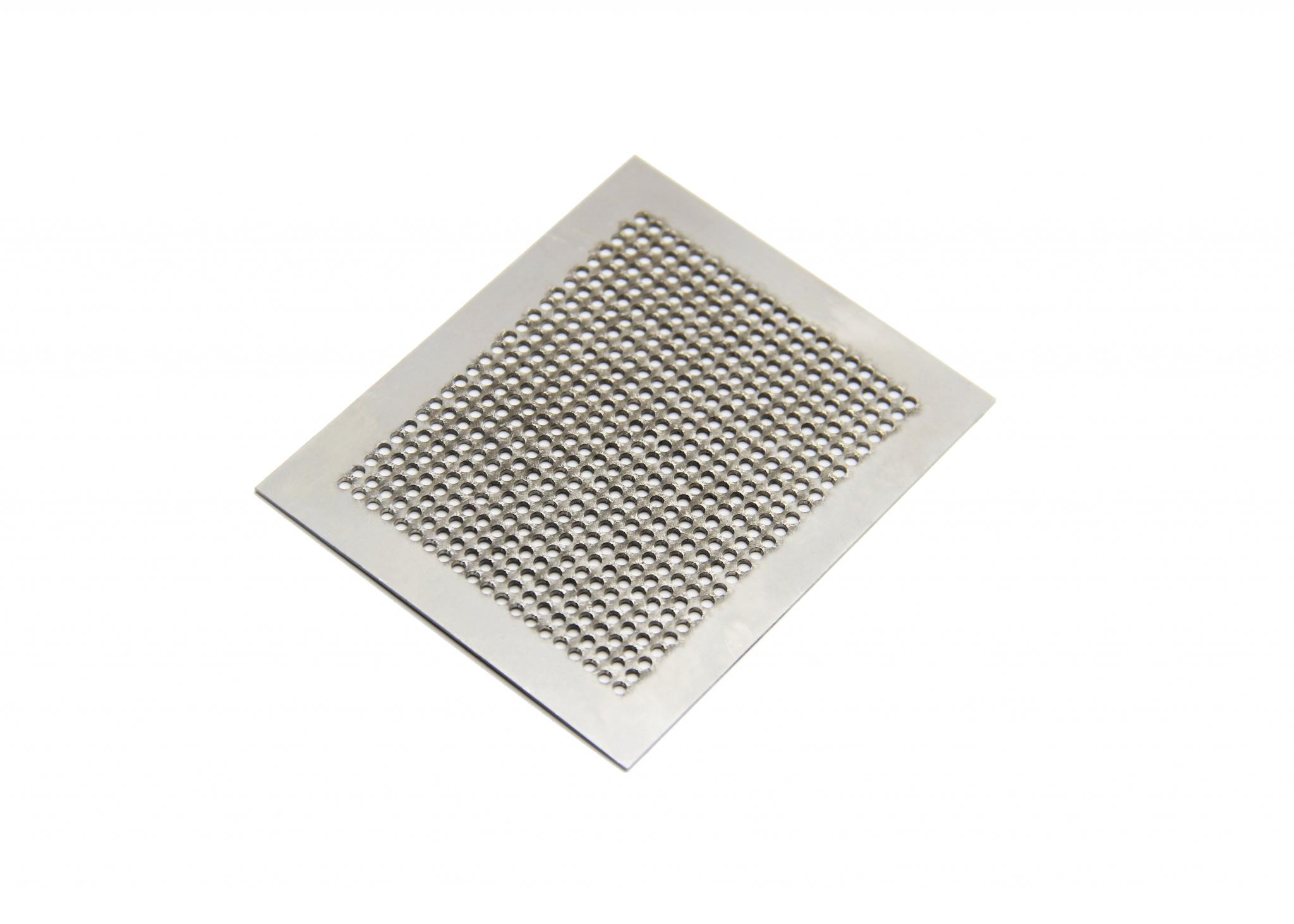

Platino Fiber Laser & Tower clear the air for higher productivity at ventilation manufacturer

Soler & Palau (S&P) Ventilation Group is the world’s leading fan manufacturer. The company offers a wide range of ventilation products benefiting from over 60 years of experience within the industry.

Snow- and ice-free roads even faster now

After about thirty years, Giletta, a company that is part of the Bucher Municipal group, a landmark in the production and sale of snow removal machines and equipment, decided to bring the steelwork department back in-house by installing a new fiber laser cutting system and a servo-electric press brake both by Prima Power.

Riding the Night Train to Higher Productivity

The Minerva Group in Bologna, Italy is a company that truly embodies skills, technology, and entrepreneurial spirit.

Laser Genius: a smart buy for Midwest Job Shop

For the past five years, R & M Manufacturing has faced an interesting challenge. The company has experienced a strong growth cycle, and projections are even stronger for the future with such customer industries as electrical, power generation, solar, air purification, HVAC, home & building, etc.

Top performance

With over a decade of experience in laser cutting and sheet metal bending, Laserlam constantly looks to new solutions to increase its productivity, such as Prima Power’s new 2D Laser Genius+.