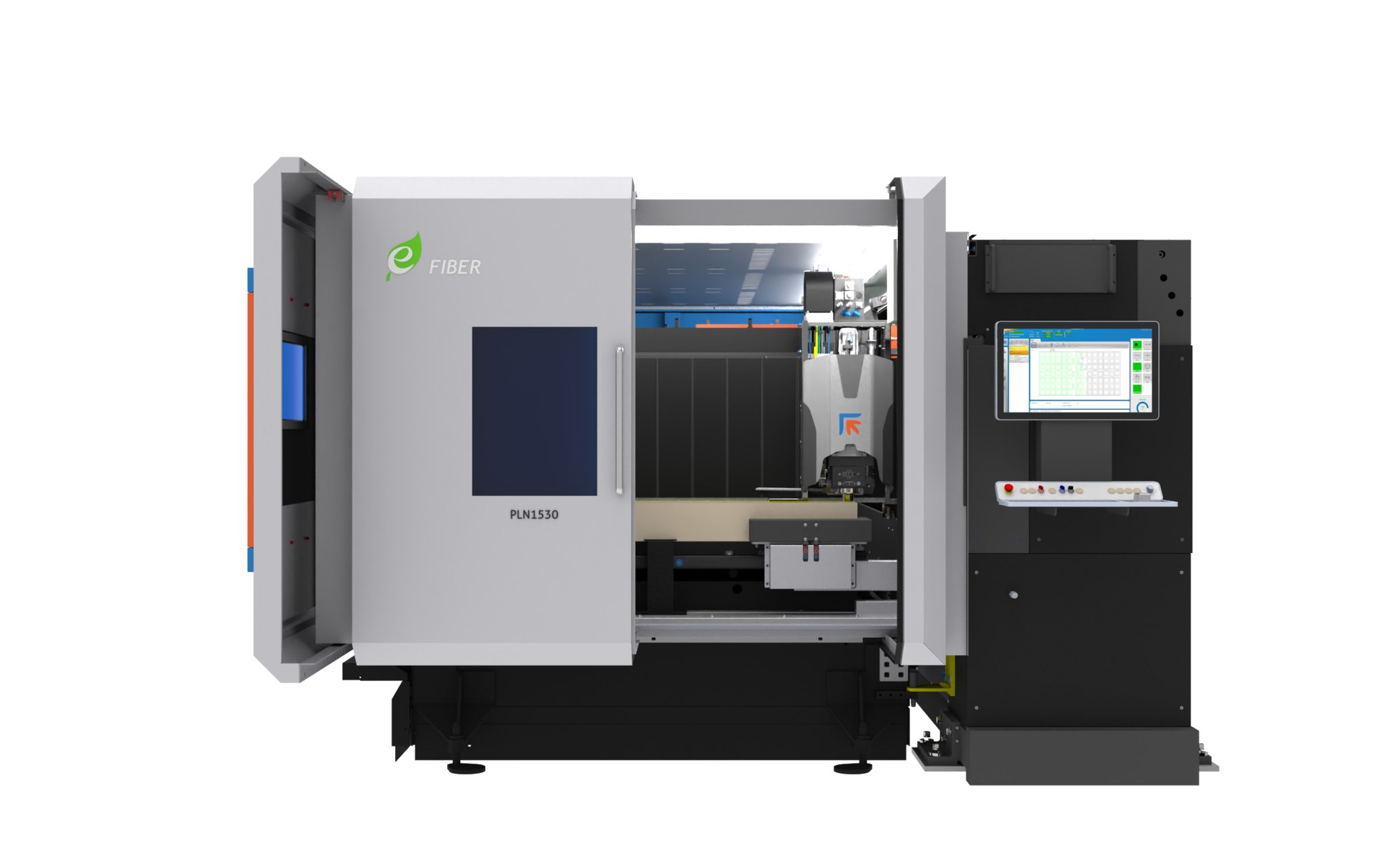

Platino Linear

2D LASER CUTTING MACHINE

The reliable and productive solution for cost-effective 2D laser processing

Efficient and easy-to-use laser cutting machine: the ideal affordable solution for the processing of any material and shape with high cutting quality and great reliability.

Maintenance-free linear drive enhances machine uptime resulting in reduced operating costs due to high energy efficiency. This makes Platino Linear the ideal affordable solution for processing any material and shape.

Best-in-class throughput per square meter thanks to a reduced footprint by 22%.

Lower cost per part through gas savings up to 40%, reduced energy consumption (+40% wall-plug efficiency), and up to 96% sheet utilization.

Platino Linear® is the latest addition to the Prima Power 2D laser product range, resulting from the perfect balance between Prima Power expertise and quality at affordable investment and operating costs.

Platino Linear is an efficient, and easy-to-use laser cutting machine designed for the processing of any material and shape with high cutting quality and great reliability. It is a durable and long-lasting machine that delivers flawless results thanks to its robust and sturdy design.

Its highly dynamic, maintenance-free linear drive increases machine uptime compared to conventional drive systems, resulting in high productivity, especially when processing thin materials.

The Platino Linear is extremely cost effective with an unbeatable output per m2 in the category, best-in-class plug-in efficiency and incredibly sustainable sheet utilization up to 96%.

Its user-friendly interfaces provide straightforward operation and a variety of smart features that enable effortless automation and connectivity.

Platino Linear is a modular solution that can be integrated with a wide range of automation modules for loading, unloading, picking, sorting, and stacking sheets and parts. Its modularity allows Platino Linear to evolve with your production by integrating different types of automations.

- Synthetic granite frame: unparalleled accessibility to the working area, combined with superior vibration absorption, thermal stability, and weather resistance.

- Aluminum carriage: reduces the weight of moving parts while maintaining ideal rigidity resulting in high accuracy.

- Adaptive laser head: superior cutting quality and outstanding performance on all materials with a single focusing lens that can be adapted to meet different production requirements.

- Protection cabin: highly accessible cabin with full-length side opening for sheet metal loading and front door for easy maintenance.

- Tech suites: dedicated technological suites for optimizing machine performance depending on the application. The ECO-TOUCH Cut and Gas Mixer options allow for dramatic reduction in gas consumption of up to 40%.

Working Area

Platino Linear 1530 | X= 3,048 mm; Y= 1,524 mm; Z= 150 mm

Axis speed

100 m/min (trajectory 140 m/min)

Position accuracy (Pa) and Repeatibility (Ps)*

0.03 mm

Fiber laser source

2000 W - 4000 W - 6000 W – 8000 W

*according to VDI/DGQ 3441 standards: the precision of the part depends on its type, pre-treatment, and on the application conditions.

Optimize your Prima Power machine

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Optia

OPTIA

OPTIA grants an extraordinary simplifying of sheet scraps recovery process.

Wizard

MACHINE PROGRAMMING

Revolutionary CAM application, Nesting, technology, and machine code in 4 steps to combine ease of use and quick machine preparation.

2D Editor

H.M.I.

A precise and efficient cutting depends on a correct post-processor.

Related technologies

RELATED AUTOMATIONS

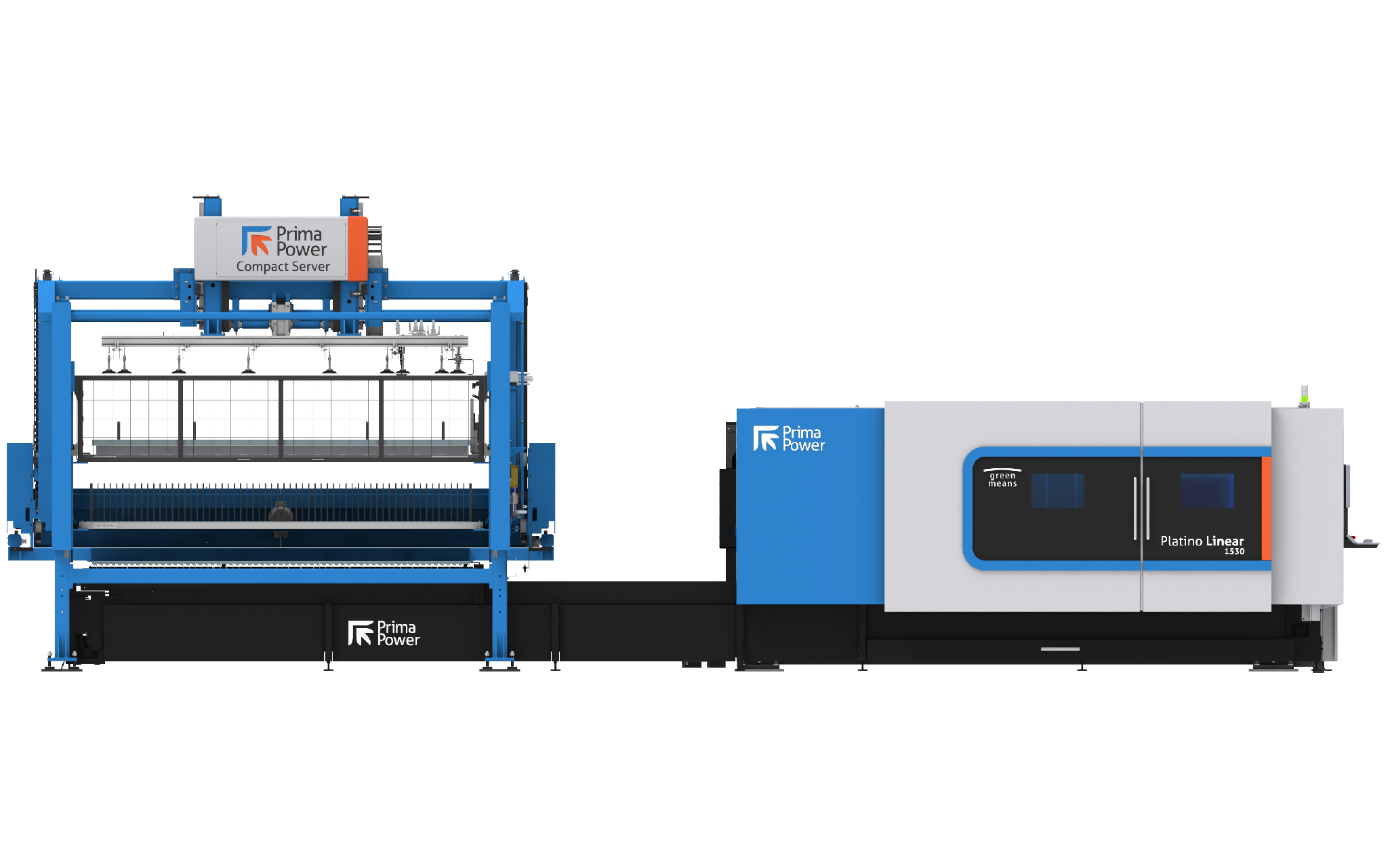

Compact Server

MATERIAL HANDLING

Automatic loading and unloading device for raw material and processed sheets for 2D laser machines

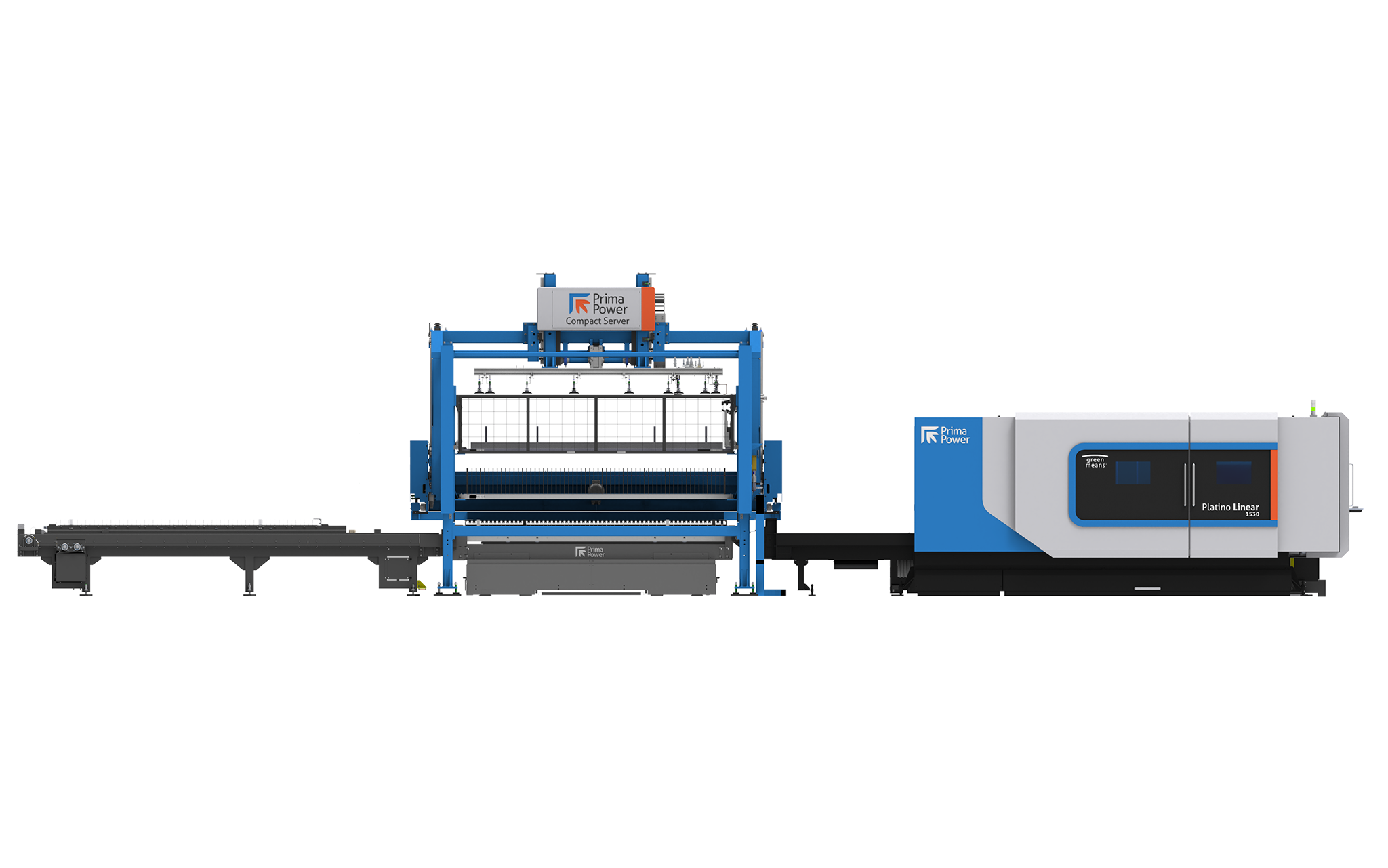

Third pallet station

MATERIAL HANDLING

Automatic pallet changer (PA) with additional loading / unloading station.

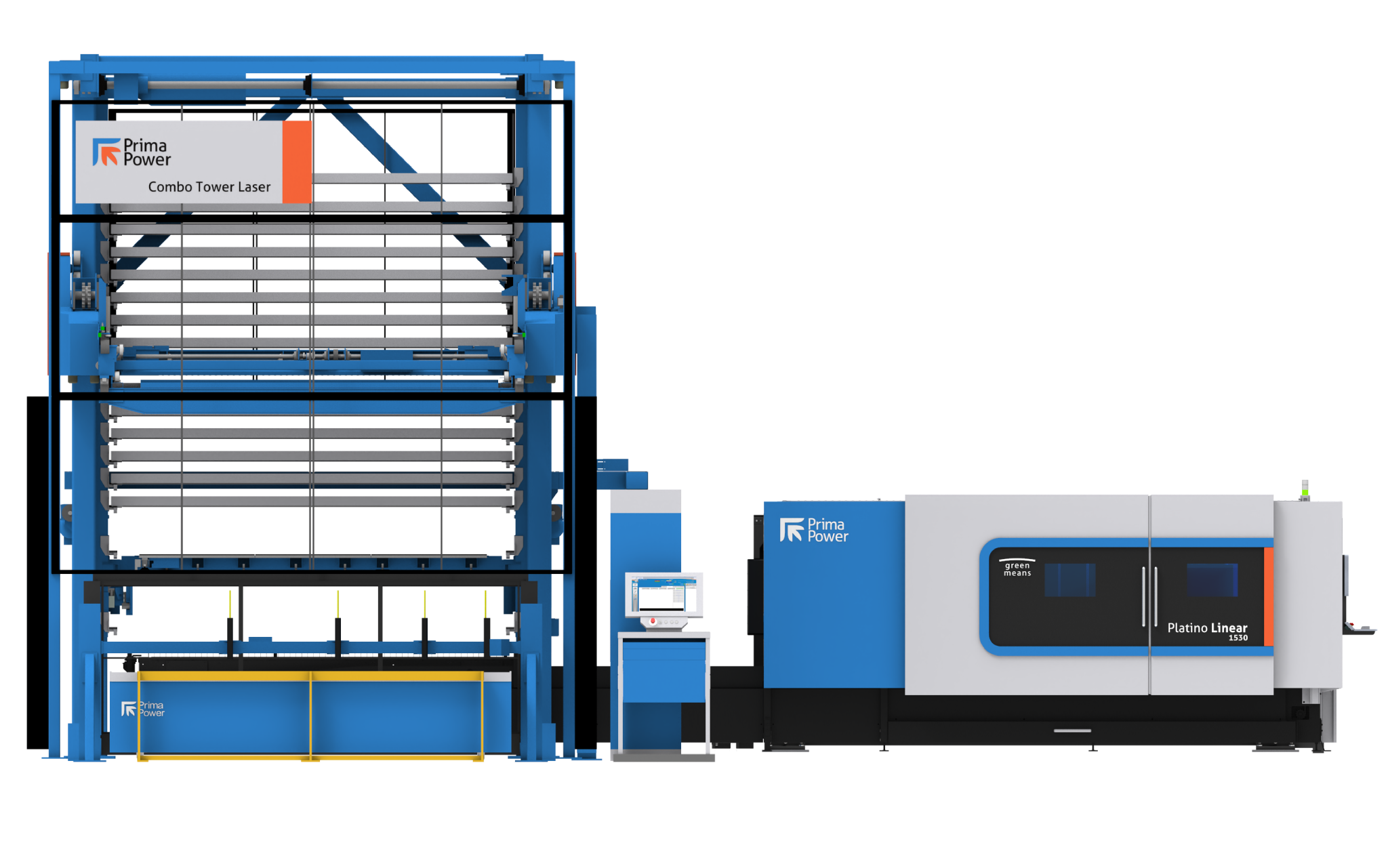

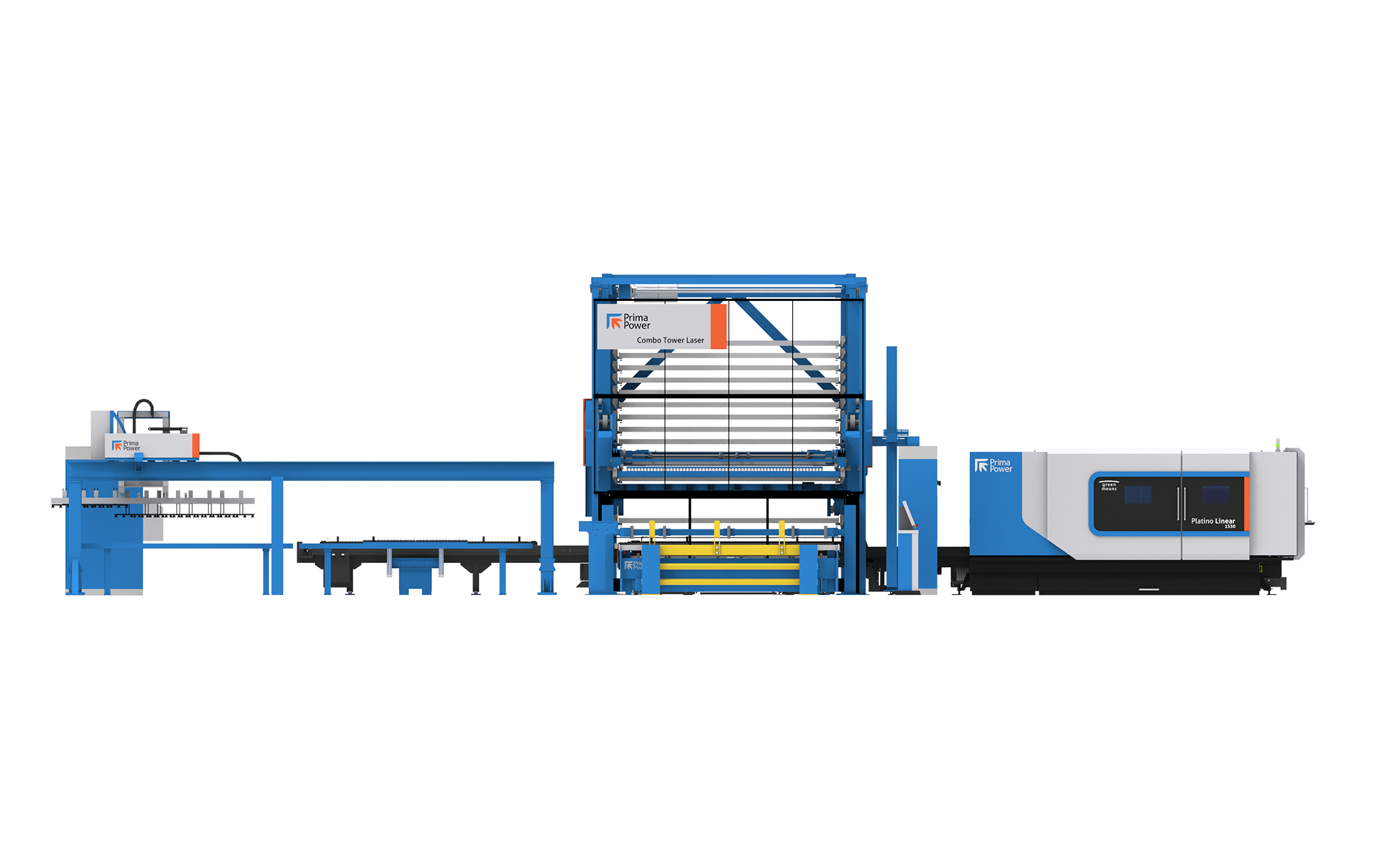

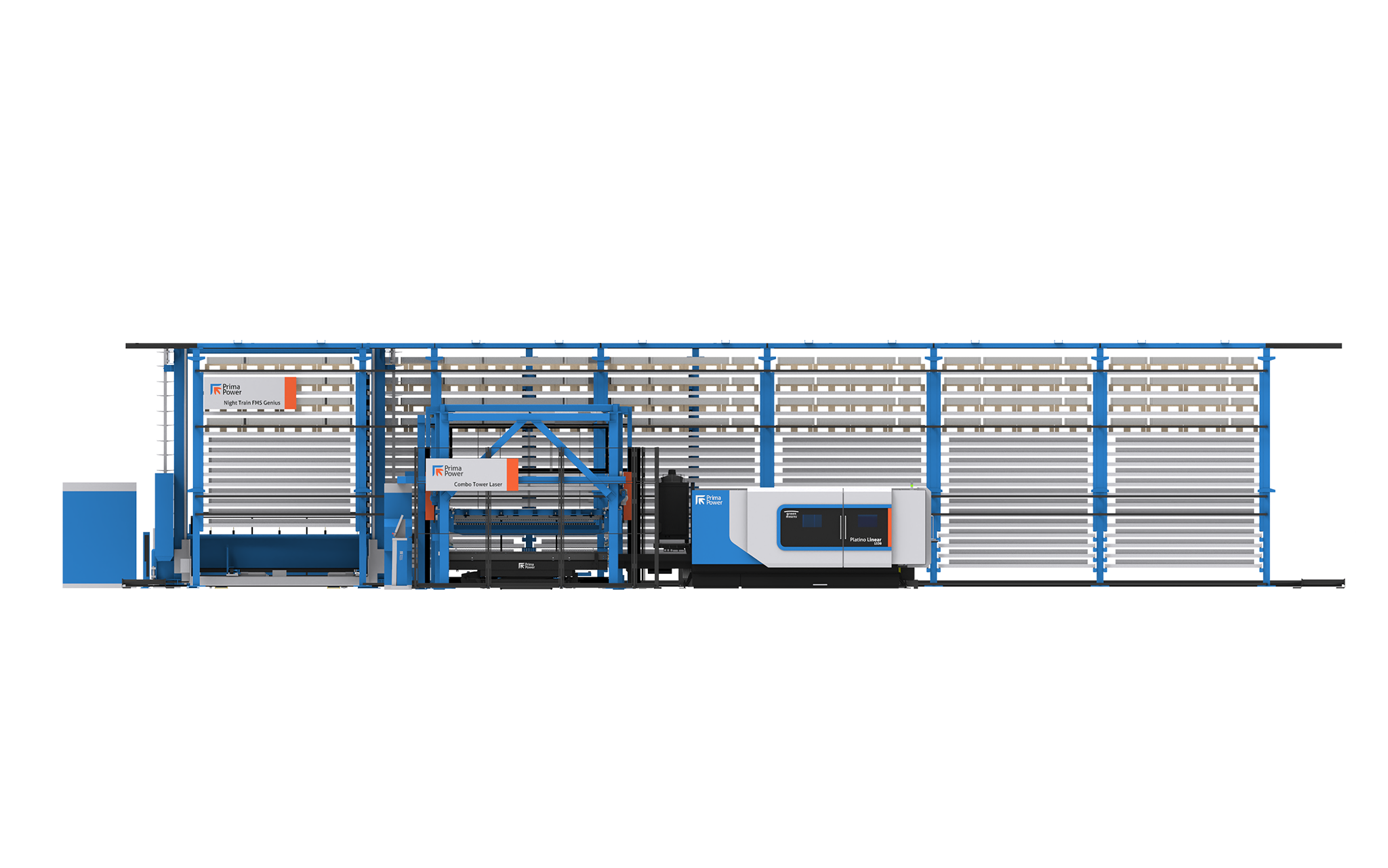

Combo Tower Laser

STORAGE SOLUTIONS

The key module to automate material flow with 2D laser machines

Picking and stacking robot (PSR)

MATERIAL HANDLING

The clever and flexible picking and stacking robot

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Take a look at the other products and choose the best solution

Laser Genius+

2D LASER CUTTING MACHINES