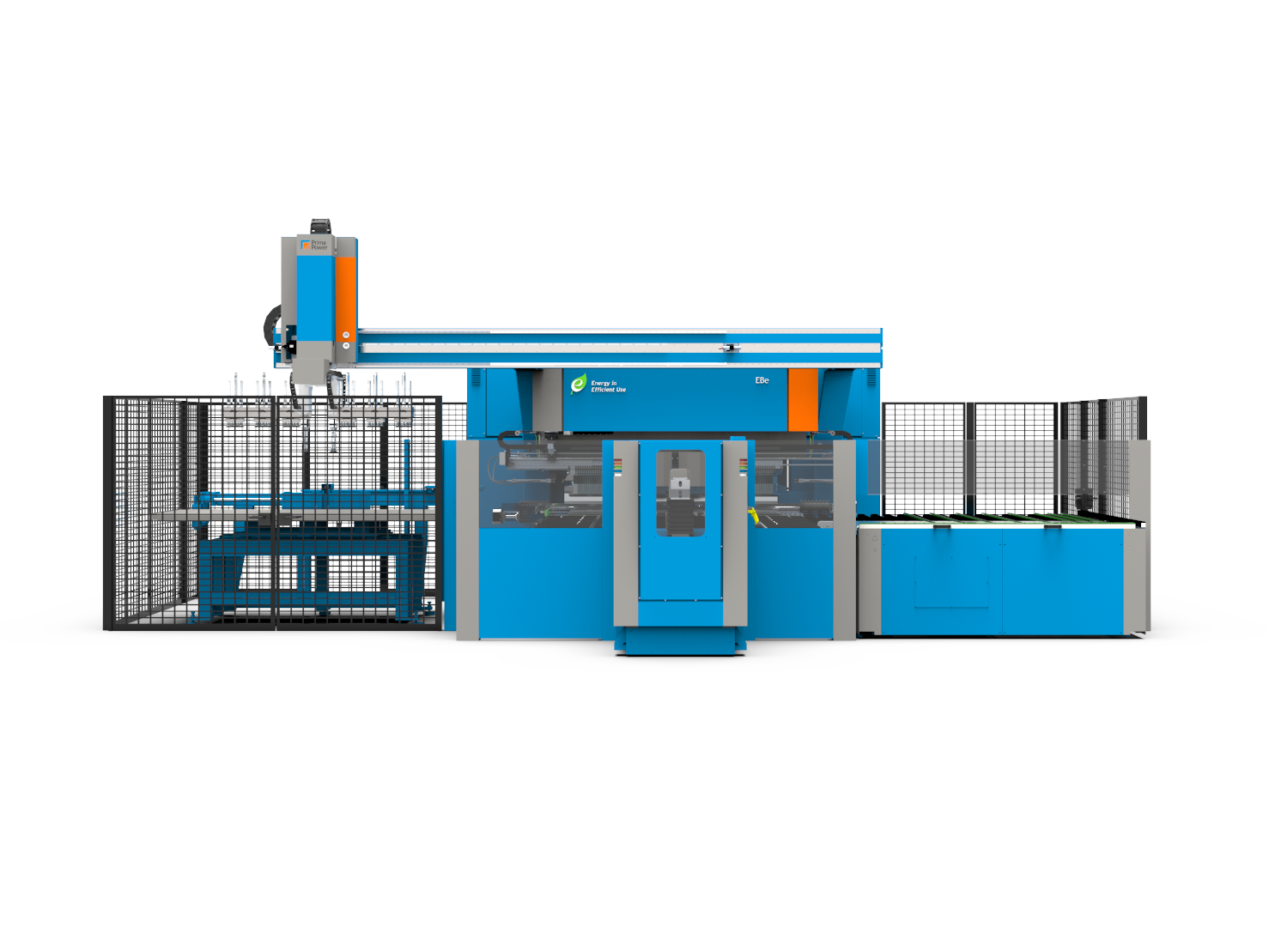

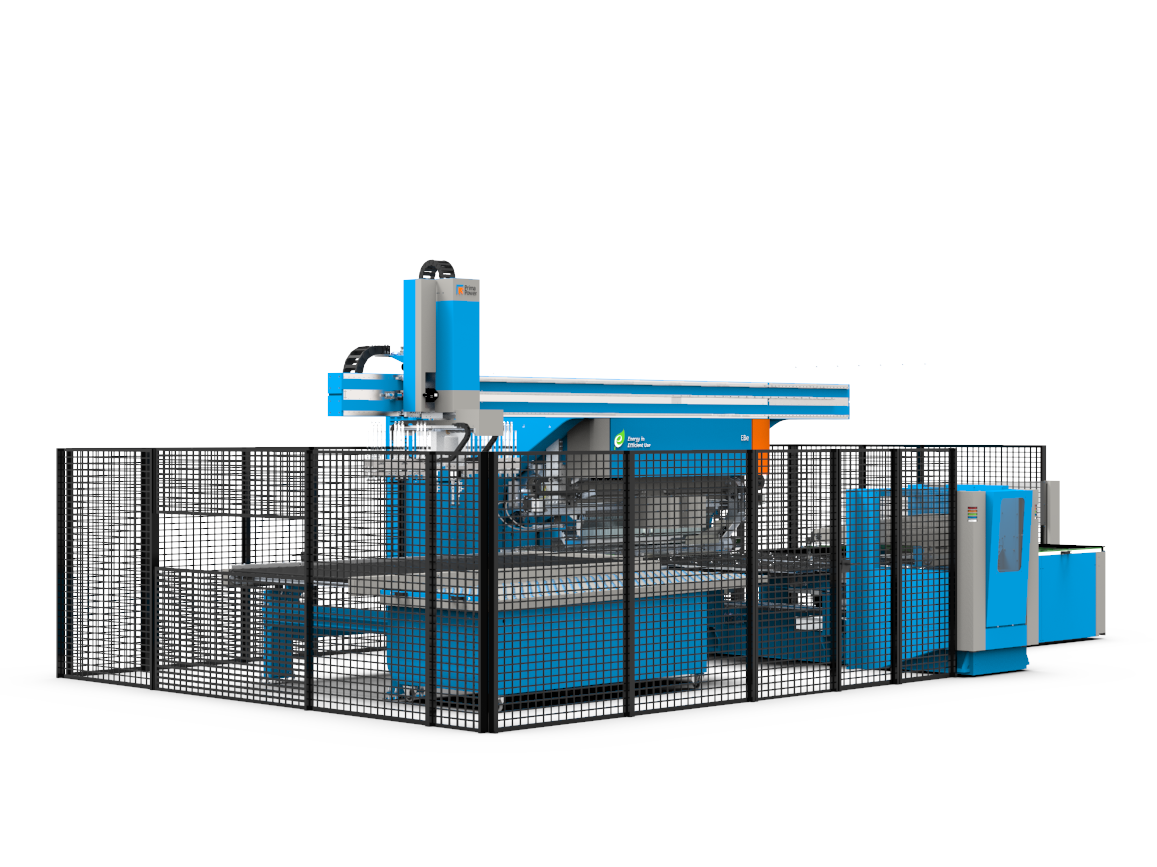

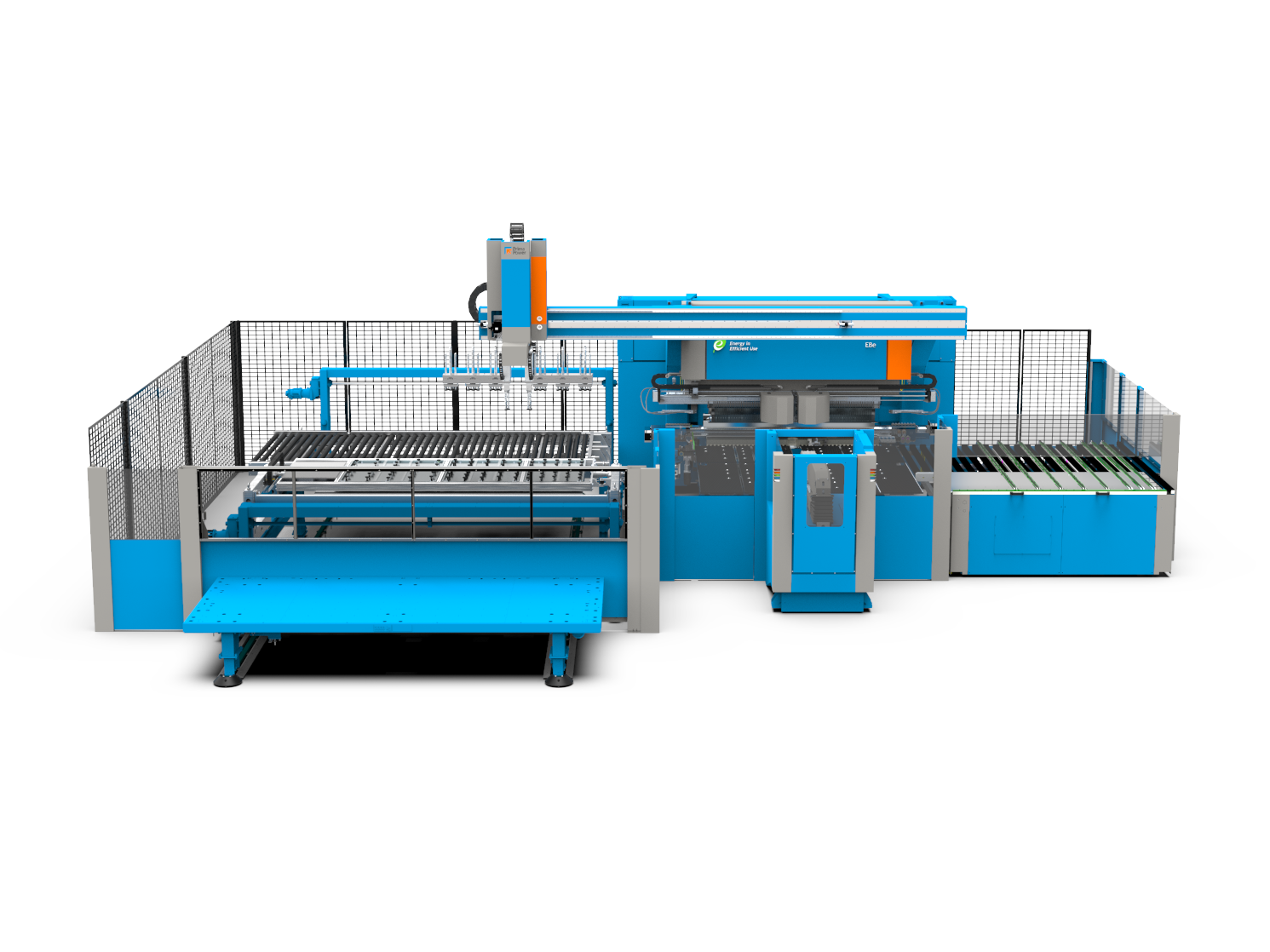

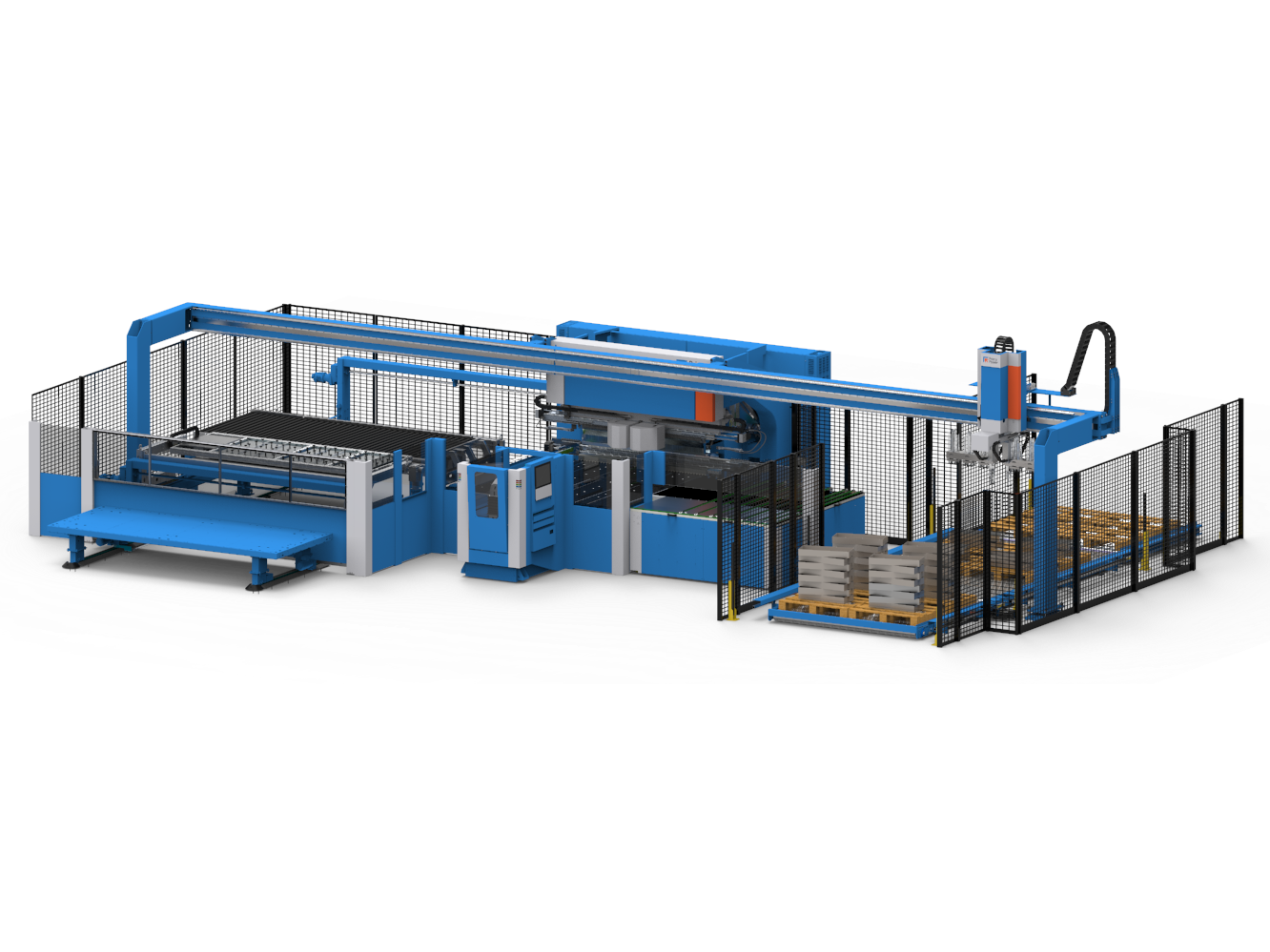

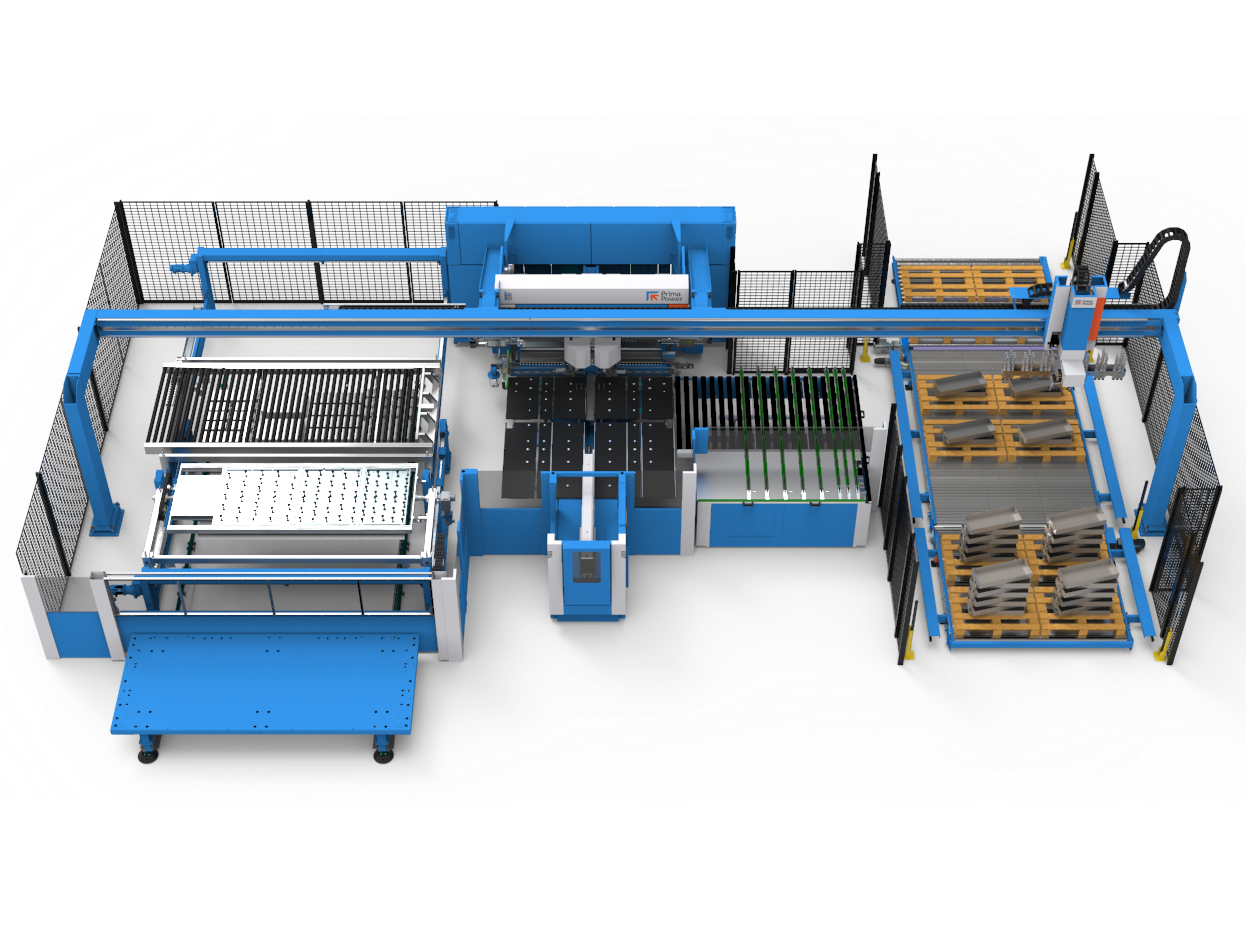

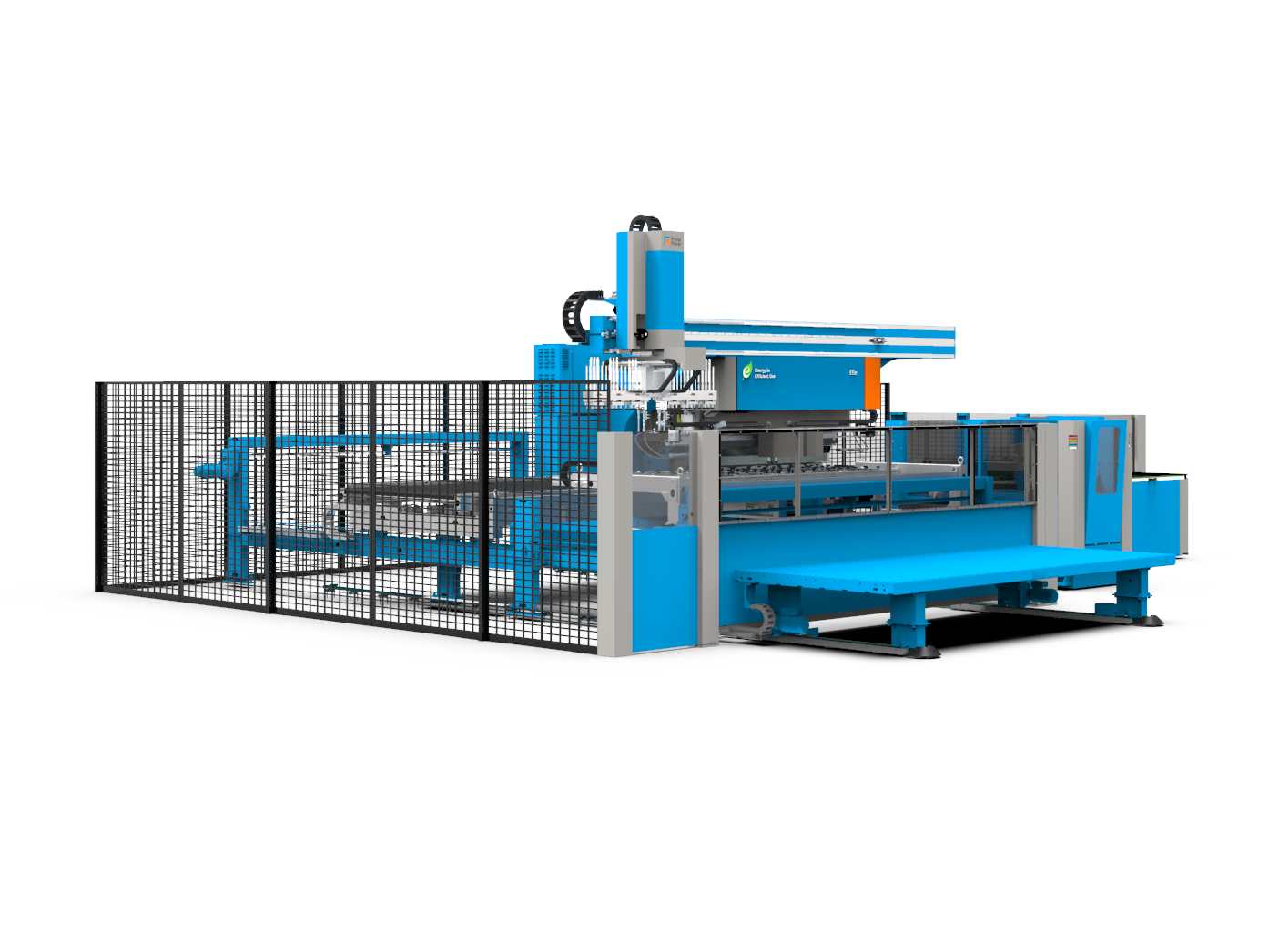

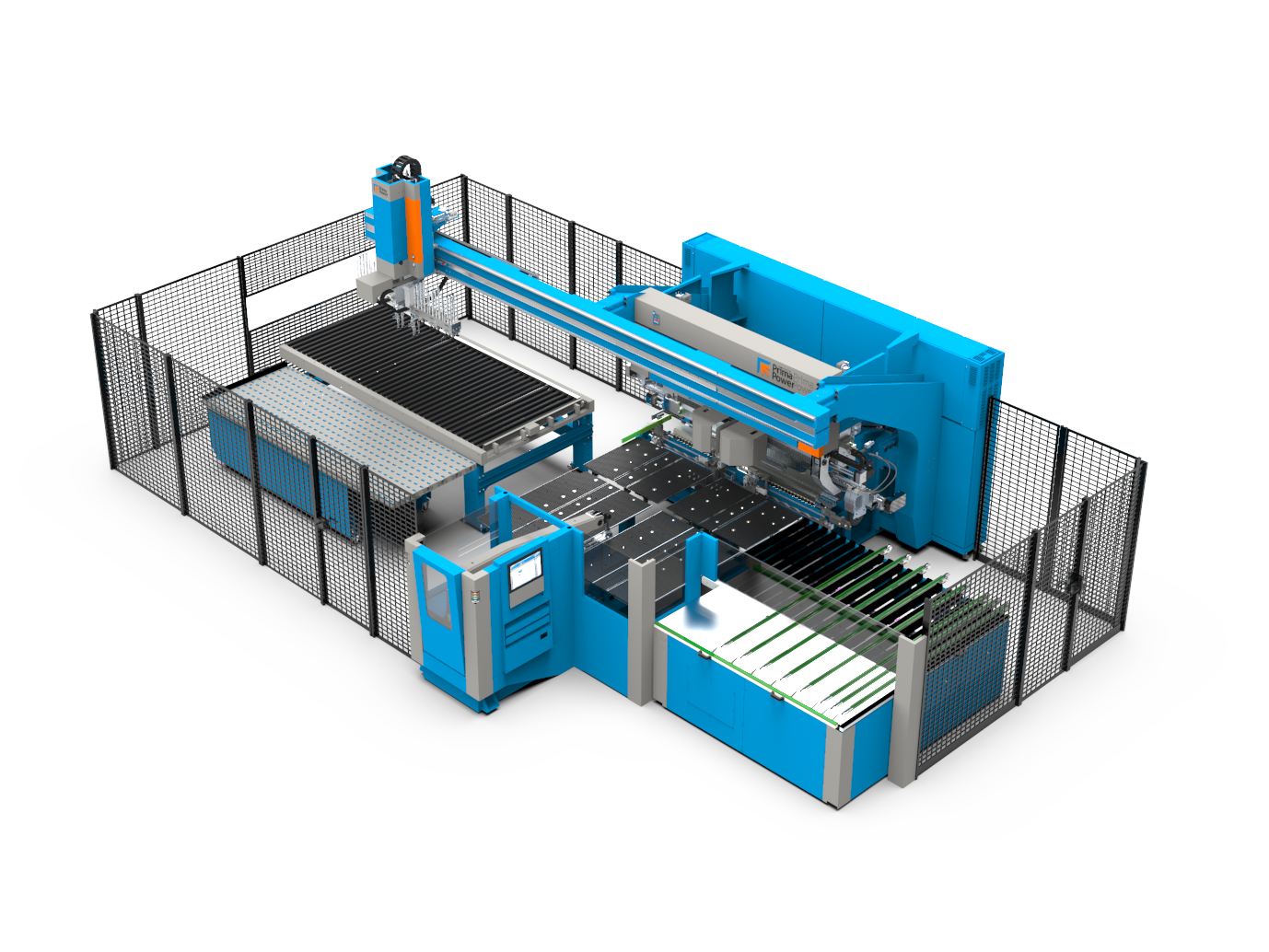

EBe Express Bender

PANEL BENDERS

Productivity pushed to the maximum.

PRECISE

Excellent bending quality thanks to the angle correction database and servo-electric technology.

FAST

Reduction of cycle times with loading and unloading operations in masked time.

SCALABLE

Suitable for every production requirement thanks to the complete range of automation, loading and unloading solutions.

EASY

3D programming with integrated simulation of the bending cycle.

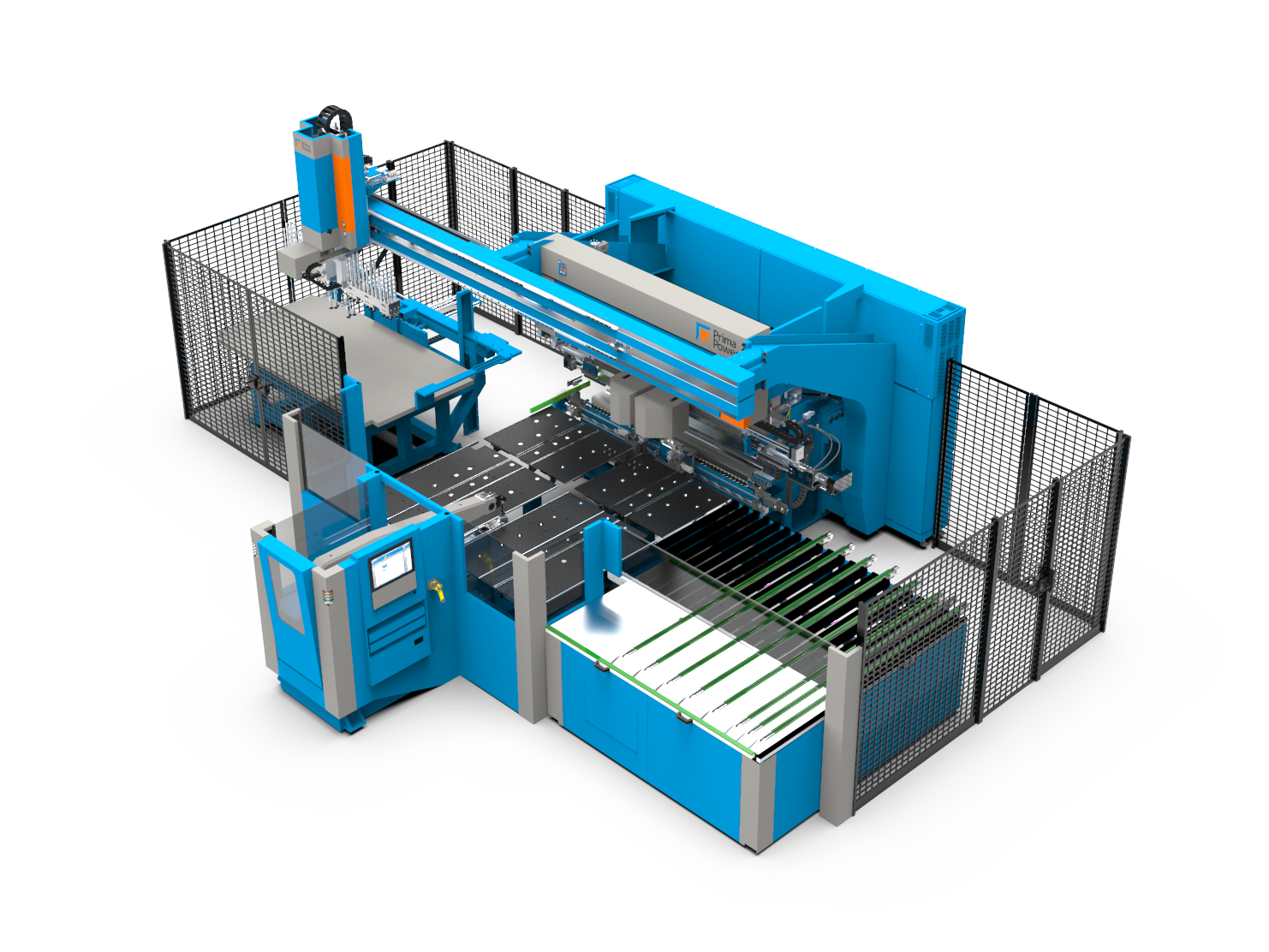

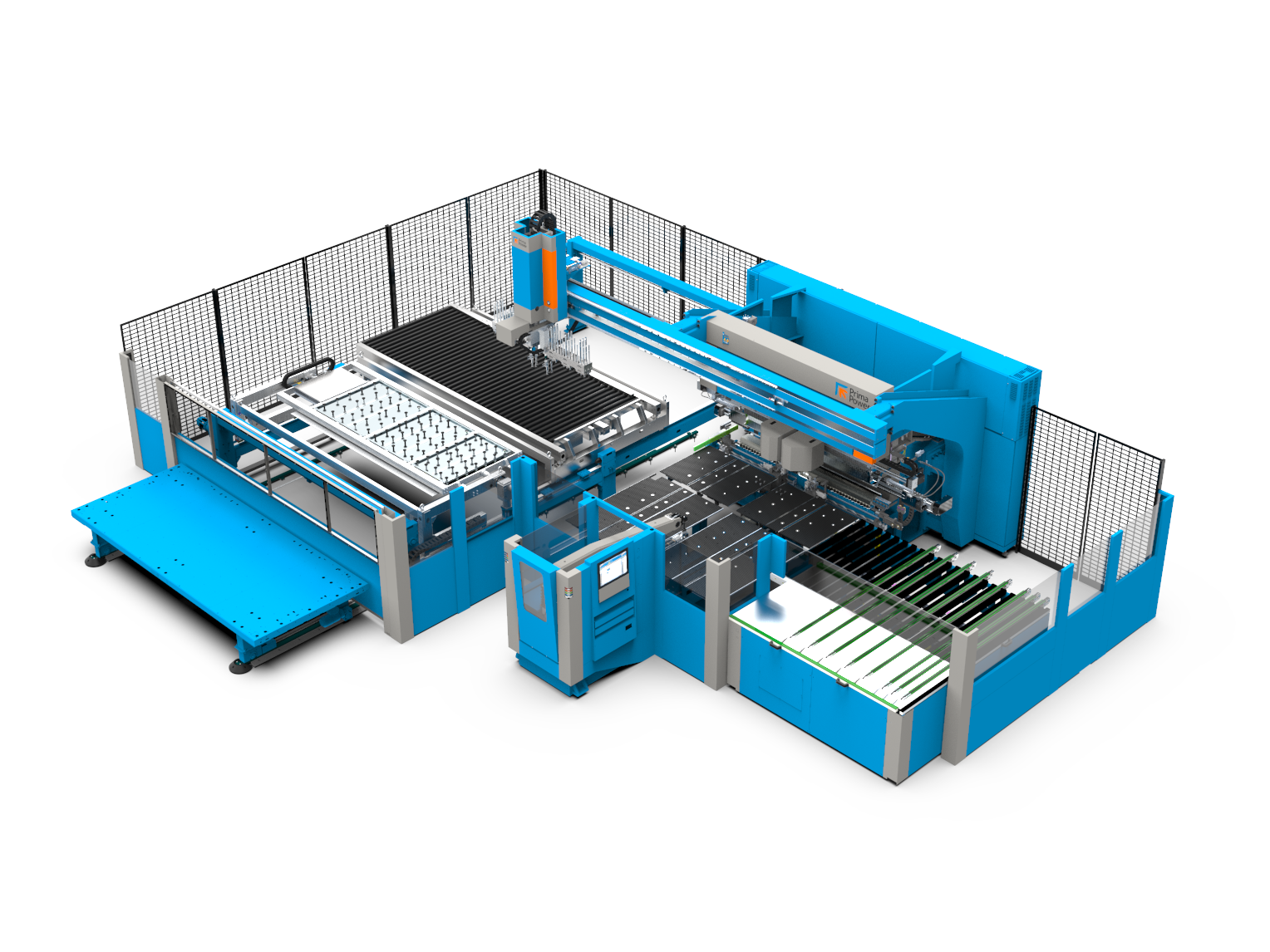

Prima Power’s EBe Express Bender is the servo-electric panel bender which considerably increases the production capacity thanks to the automated loading and unloading process, thus maximising the efficiency of the bending process. In the EBe stand alone version, there is a loading table for loading large quantities of the same part: this configuration is suitable for larger production volumes with limited variability.

The PCD device is an alternative with greater automation when loading several stacks of different pieces - with an optional turning device - which allows batch or kit production and prepares the panel bender for future connection with other Prima Power machines.

|

EBe2220 EBe2226 |

EBe2720 EBe2726 |

EBe3320 EBe3326 |

EBe3820 EBe3826 |

|

|

Maximum bending length |

2,250 mm |

2,750 mm |

3,350 mm |

3,800 mm |

|

Maximum sheet length |

2,850 mm |

3,850 mm |

4,000 mm | |

|

Maximum sheet width |

1,500 mm |

1,700 mm | ||

|

Maximum panel diagonal |

3,000 mm |

3,950 mm |

4,000 mm | |

|

Maximum bend height |

204 mm 264 mm |

|||

|

Maximum re-entering bend |

55 mm |

|||

|

Bending force |

32t(320kN) |

41t(410kN) |

||

|

Clamping force |

52t(510kN) |

90t(890kN) |

100t(980kN) |

|

|

Max. thickness, Steel UTS 410 N/mm2 |

3.0 mm |

3.2 mm |

3.0 mm* 3.2 mm** |

2.0 mm* 3.2 mm** |

|

Max. thickness, Stainless steel UTS 680 N/mm2 |

2.0 mm |

2.2 mm |

2.0 mm* 2.2 mm** |

1.5 mm* 2.2 mm** |

|

Max. thickness, Aluminium UTS 265 N/mm2 |

4.0 mm |

4.0 mm |

3.5 mm* 4.0 mm** |

3.0 mm* 4.0 mm** |

|

Minimum thickness |

0.5 mm |

|||

|

Average absorbed power |

6.5 kWh |

7 kWh | ||

The values shown refer to a standard machine. Prima Power reserves the right to change data without notice.

*Full length - **Max. 3,000 mm

Optimize your Prima Power machine

Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

RELATED AUTOMATION

Robotic Bending Cells

ROBOTIC BENDING CELLS

Full performance optimization into your arms

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Take a look at the other products and choose the best solution

FBe Fast Bend

PANEL BENDERS

The answer to multiple applications. Semi-automatic bending solution for simple, flexible and accessible production

BCe Smart+

PANEL BENDER

New semi-automatic panel bender to level up your flexibility and productivity with the right balance

BCe Bending Centre

PANEL BENDERS

Flexibility at your service semi automatic panel bender combining flexibility and productivity

SUCCESS STORIES

Find out how a Prima Power EBe machine took part in a company's success

Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

Prima Power EBe Express Bender Increases Productivity & Quality at Georgia Job Shop

When Randy Williams opened his job shop, he was already a seasoned fabricator. “I grew up with metal fabrication,” explains Williams. “My dad was an aerospace engineer who built trampolines part-time when I was 10 years old, and I helped build parts in the basement. His business evolved into making ferris wheels and other portable amusement rides, but eventually the liability insurance became too challenging for the small company.”