Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

MORE CAPACITY

Less man hours and more machine hours through unmanned operation

NO SETUP TIME

Practically zero time for setup changes – fast, automatic change from one product to another

FASTER PRODUCTION

Shorter lead time for product changes and new products

AUTOMATION 24/7

High and even component quality

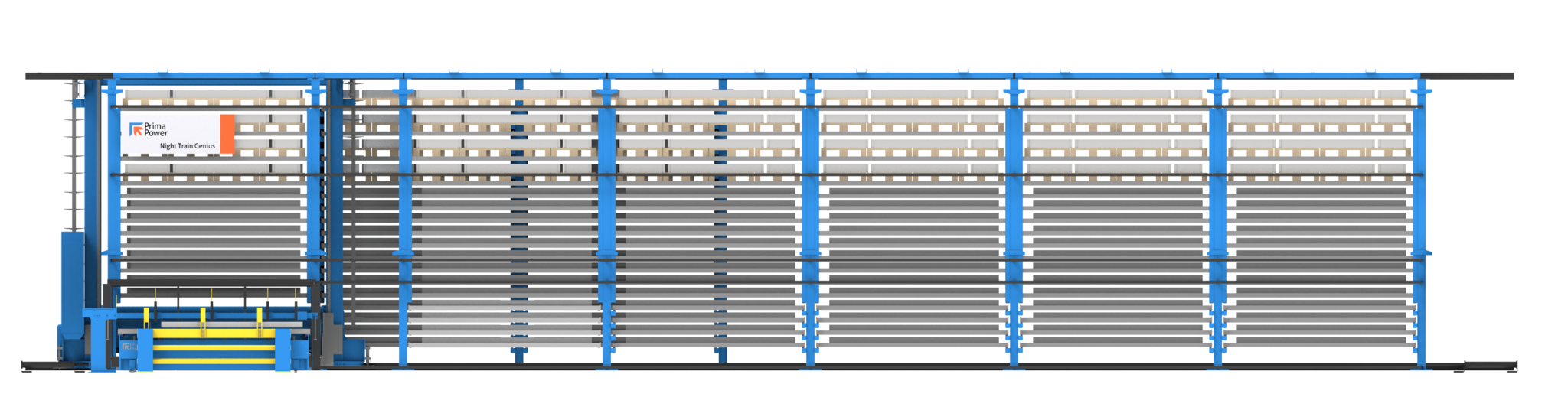

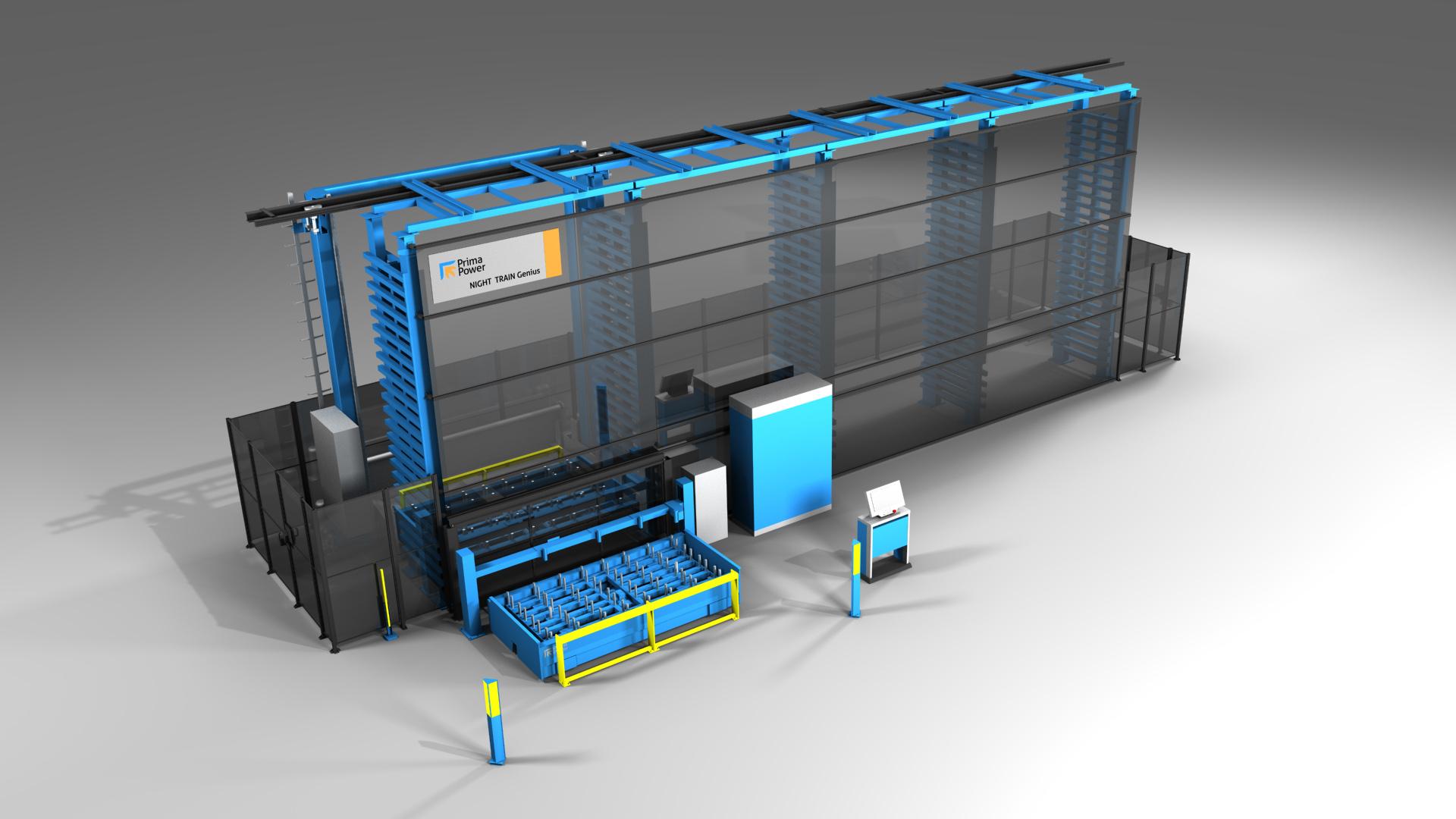

Prima Power’s automated storage solution Night Train FMS® is leading technology in automated flexible manufacturing. Low profile crane and shelf structure offer excellent storage capacity with a smaller footprint.

Trains don’t stop for the night – why should your production?

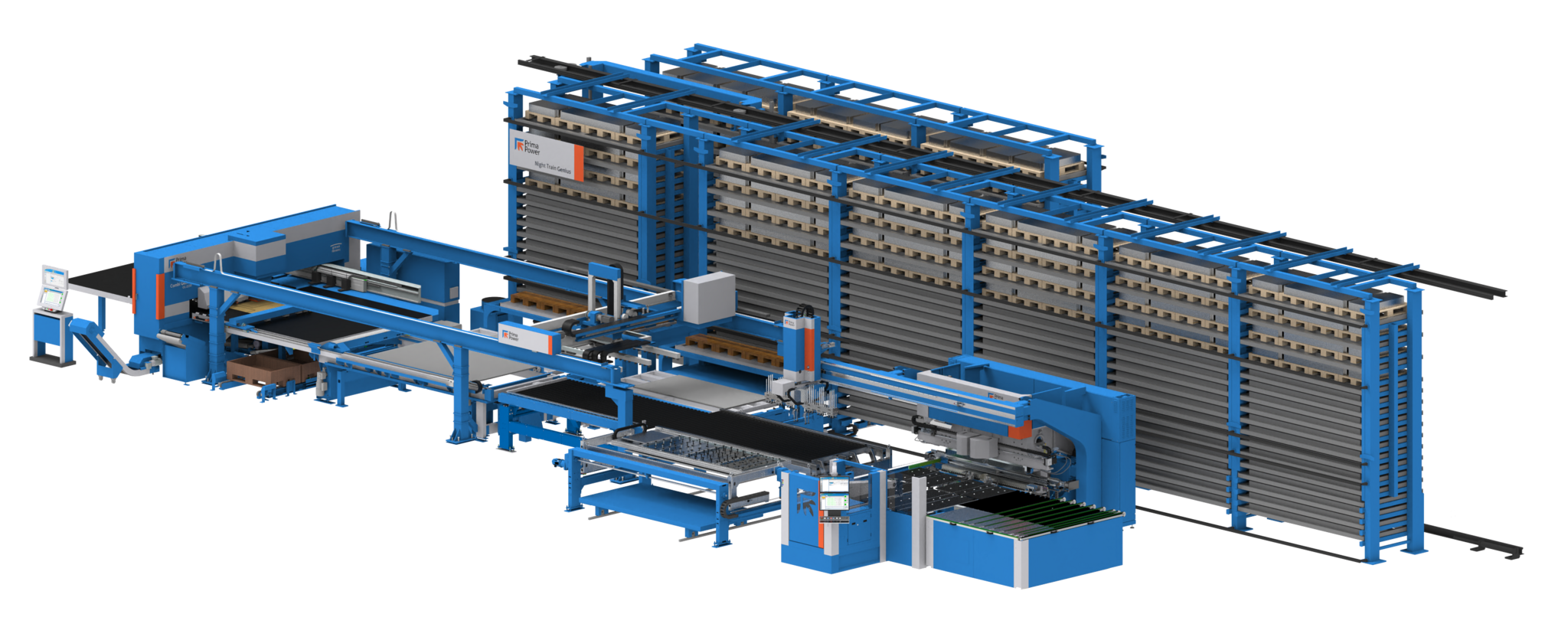

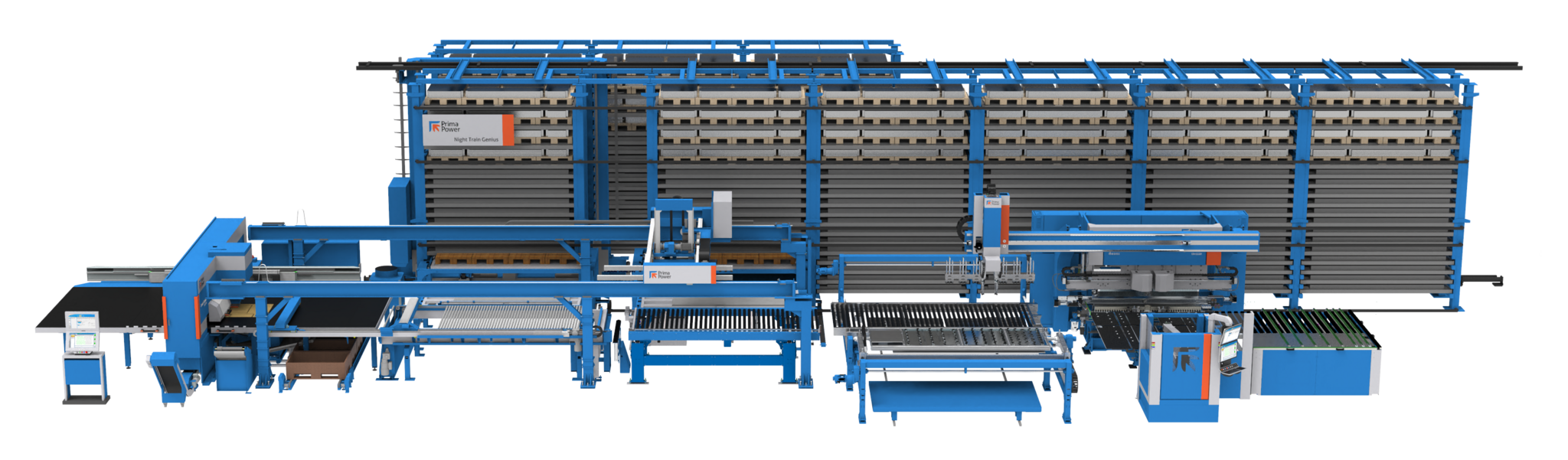

Night Train FMS® automates the material and information systems of a facility and combines individual manufacturing stages into a single flexible process. Systems are customized using the wide Prima Power range of high-performance machine tools, integrated cells, automatic material handling solutions and software. Due to the wide range, the right solution can be found for every application and all system sizes. Night Train storage solution can serve both as a material storage and as a buffer storage for parts.

Prima Power’s SYSTEM technology provides flexibility beyond our own range of machines and cells. The standard Prima Power interface also allows the integration of other suppliers’ machines in the system.

HIGHLIGHTS

- Automatic information flow from programming to production reporting,

- An integrated production system, reducing the whole fabrication process into a single one,

- Automatic manufacturing stages,

- Automatic material handling including intelligent buffering,

- Minimum manufacturing time, and maximum production time

Optimize your Prima Power machine

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

Tulus Storage

H.M.I.

Software for Combo Tower Laser and Night Train is a touch-operated user interface with visual and modern look and feel.

Related technologies

Take a look at the other products and choose the best solution

PunchBend

FLEXIBLE MANUFACTURING SYSTEMS

From cut-to-size material to ready-bent components

SUCCESS STORIES

Find out how a Prima Power Night Train FMS machine took part in a company's success

Order and efficiency drive productivity, from first cut to finished product

Astra was founded just short of thirty years ago as the result of an innovative instinct which proved successful in just a few years: that stainless steel would become the technological material of the future.

Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

Automation as a Competitive Edge

Thanks to integrating a Prima Power fully-automatic laser cutting system, consisting of a 6 kW Platino Fiber 2.0 laser cutting machine, along with a Night Train automated warehouse, Carpenteria Metallica Depedri has been able to increase productivity by 30%.

New investments create productivity at Halton’s Kausala factory

Halton Group is the world's leading provider of indoor air solutions. Indoor air solutions are divided into four segments: Marine, Health, Foodservice, and Buildings

Prima Power PSBB Helps Power Generation Giant Build Flexible Manufacturing System

Headquartered in Spain, with 8 production centers, 13 subsidiaries worldwide, and a global network made up of 1,000 employees who work closely with more than 130 distributors around the world, HIMOINSA, part of the Yanmar Group, is one of the top global giants that designs, manufactures and distributes power generation equipment.

A look at the technology behind turnkey organic poultry plants

SKA srl manufactures poultry systems for organic free-range farming with high levels of product customisation by taking advantage of innovative Prima Power technology.