LBB

FLEXIBLE MANUFACTURING SYSTEMS

Lights-out production capacity with outstanding flexibility

FLEXIBILITY

Suitable for a wide range of materials and thicknesses

VERSATILITY

Outstanding versatility for complex manufacturing

TRANSPARENCY

Automatic information flow from programming to production reporting

USER FRIENDLY

Ease of operation, minimal set-up times

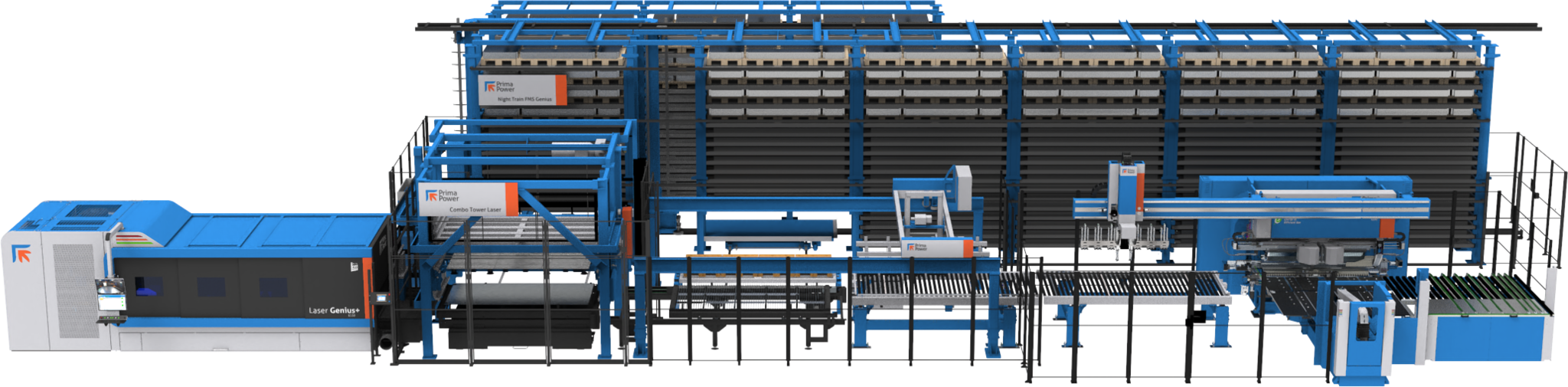

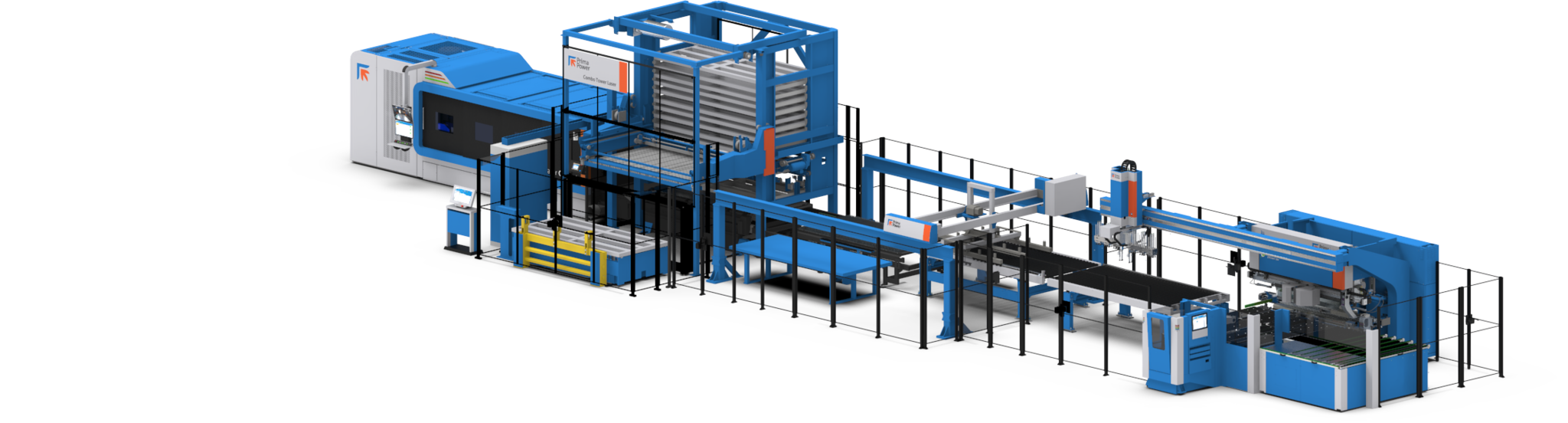

LBB

Laser cutting / Buffering / Bending

The automated LBB production line integrates laser cutting, intelligent part handling and high-quality bending. It combines the best sides of 2D laser cutting and bending: great lights-out production capacity together with outstanding flexibility of the automated material flow and bending process.

Laser cutting is a flexible productive technology having the ability to process a wide variety of materials with the widest material thicknesses available. Precision is also the highest, cutting quality is excellent and no distortion of parts occurs.

The flexible and versatile buffering function ensures optimum operation whatever the manufacturing task at hand. Buffering guarantees that the production process is always as flexible, fast and smooth as it can be.

For the bending part of the line, you can choose either a servo-electric high-accuracy panel bender or a press brake, which is excellent with thicker materials and complex shapes. Prima Power panel benders are versatile and flexible and can be customized with a range of options.

To increase the efficiency of the line even further and tailor it to specific needs, it is possible to add more automation with an automatic storage or a loading and stacking robot – the combinations are nearly limitless.

The productivity offered by this concept derives from integration of:

• Modern laser cutting

• Servo-electric bending

• Automatic, flexible material flow and

• Sophisticated software

RELATED AUTOMATIONS

관련 기술

RELATED AUTOMATIONS