The global aiot innovator invests in state-of-the-art equipment to produce high value-added products

SUNSEA AIOT Technology’s subsidiary in Zhuhai pioneers smart factory innovation with cutting-edge machinery. The world-class factory serves both domestic and international markets.

“SUNSEA AIOT has made significant investments in the Zhuhai smart factory with the aim of setting a new standard for smart factories in China”, states Luo Yuanping, production director of the Zhuhai plant.

In 2020, SUNSEA AIOT Technology Co., a high-tech enterprise listed on the Shenzhen Stock Exchange and the world’s first AIoT (Artificial Intelligence of Things) innovator, decided to invest hundreds of millions of RMB in a world-class smart factory for the production of ICT infrastructure equipment and other smart device products in its Zhuhai subsidiary.

PURSUING GROWTH THROUGH STATE-OF-THE-ART EQUIPMENT

“All workshops are outfitted with state-of-the-art equipment capable of producing high value-added products, catering to the needs of both large-scale and small-scale production runs”, says Yuanping. “The Zhuhai factory focuses on international business related to carrier base station microstation power supply and optical transmission/access network supporting products. It provides outdoor power supply cabinets for Ericsson in Sweden and microstation power supply/battery for Japanese customers’ base stations. The international business is growing very fast, with extremely strict requirements on delivery time and quality.”

“Domestic business products include ODN outdoor cabinet products, antenna feeder accessories, tower room, as well as data centers, power distribution, intelligent cabinets and power supply batteries, and other related products,” explains Yuanping. “VIP Customers include Alibaba, JD, Inspur and Wangjie Big Bata, among others. The segment for domestic optical wiring transmission, wireless sites, data centers, and network energy is also experiencing rapid growth. This business sector is characterized by intense competition due to the diverse range of products and services offered.”

Following over a year of construction, the new factory covering 53,000 square meters finished building the sheet metal workshop, welding and grinding workshop, warehouse, assembly workshop, power supply battery workshop, and painting workshop. The factory was ready for mass production at the beginning of 2022.

HIGHER EFFICIENCY WITH PRIMA POWER’S CUTTING-EDGE EQUIPMENT

“The smart factory’s sheet metal production line incorporates several automated and intelligent functions, including automatic feeding, material pickup, punching and shearing, transfer, flap operation, caching, bending, inspection, validation, stacking, scrap collection, and pre-alarm systems”, says Yuanping. “We have been Prima Power’s loyal customer for over two decades, having purchased three generations of their equipment that has consistently delivered stable performance across our factories in various cities. Therefore, when designing the Zhuhai smart factory, we opted for Prima Power’s cutting-edge sheet metal equipment, including their latest punching and shearing machines which are integrated with automatic loading equipment (LD) and unmanned production systems, as well as the high-speed transfer, punching, and stacking to different locations enabled by the automatic stacking system (STS).”

“The EBe series of servo-electric driven bending centers offers a high level of automation and customization, while the Combo Tower provides flexible material handling capabilities and serves as an intermediate storage unit for prepared components. Throughout the construction and operation of our new factory, the sales and after-sales service personnel at Prima Power impressed us with their professional pre-sales explanations, precise installation, attentive coaching, and thorough maintenance”, notes Yuanping. “Additionally, our employees were already familiar with the Prima Power production line, allowing us to quickly achieve our expected production goals with the sheet metal production line running at high speed.”

AUTOMATED PRODUCTION WITH FULLY-INTEGRATED PRIMA POWER SYSTEMS

The newly built sheet metal workshop produces cabinets and various products to different specifications that are continually coming off the production line and are organized on the AGV, ready to proceed to the subsequent welding and grinding workshop.

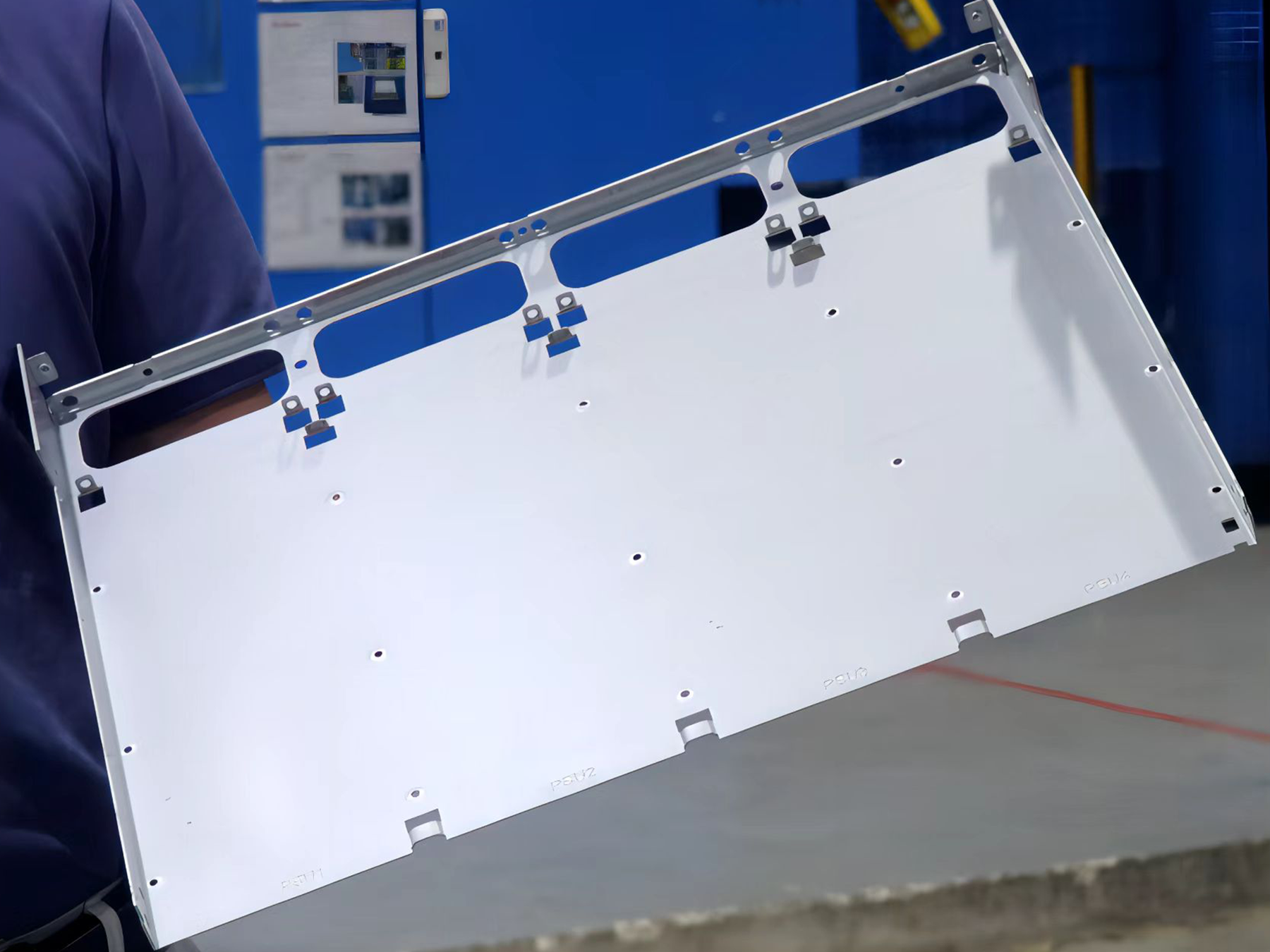

While holding a bent sheet metal part, Luo Yuanping explained: “This part was produced using Prima Power’s automated production line, which integrates multiple processes such as feeding, shearing, punching, sorting and bending into one.

The entire process is almost entirely worker-free. As you can see, this part features round holes, square holes, countersunk holes, and high-precision bending processing, with punching and shearing accuracy within 0.1mm and bending accuracy within 0.2 degrees. The consistency in processing 1000 pieces is also exceptional.”

“Over the past year, Prima Power’s equipment has demonstrated stable comprehensive performance, working long hours with good precision, great flexibility, high automation, and high overall efficiency, while requiring less manpower,” continues Yuanping. “These features enable us to achieve maximum production capacity and high-quality results that meet the demands of our customers.”

TOWARDS A BRIGHT FUTURE

“Currently, our Zhuhai factory has over 300 employees and has achieved parallel, efficient, and cost-effective production of power distribution cabinets, data storage cabinets, intelligent light poles, 5G power supplies, etc. Our production capacity allows us to produce 4,000 outdoor cabinets and 10,000 microstation battery lines per month,” adds Yuanping.

SUNSEA AIOT supplies products and services to major Chinese communication operators like Mobile, Telecom, Unioncom, and Tehta, and also to renowned international communication equipment companies such as Ericsson, Nokia, and ZTE. The Zhuhai factory aims to achieve an annual revenue of 3 billion RMB. With a positive outlook, Luo Yuanping is confident about achieving this goal in the near future.

Over the past year, Prima Power’s equipment has demonstrated stable comprehensive performance, working long hours with good precision, great flexibility, high automation, and high overall efficiency, while requiring less manpower.

The EBe series of servo-electric driven bending centers offers a high level of automation and customization, while the Combo Tower provides flexible material handling capabilities.

SUNSEA AIOT has made significant investments in the Zhuhai smart factory with the aim of setting a new standard for smart factories in China

Are you looking for a similar solution for your company? Find it here

Shear Genius EVO

MASZYNY KOMBI DO WYKRAWANIA I CIĘCIA GILOTYNĄ

Najwyższa wydajność przy integracji wykrawania i cięcia gilotyną

Combo Tower

PRZECHOWYWANIE

Sprawny przepływ materiałów i duża pojemność magazynu

eP Series

SERWOELEKTRYCZNE PRASY KRAWĘDZIOWE