Platino Fiber Laser

The Platino Fiber laser cutting machine is the perfect balance of innovation and experience. This product combines state-of-the-art efficient and ecological fiber laser technology, with the proven reliability and flexibility of the Platino platform.

“Without the Platino Fiber laser and tower, we would not have been able to keep up with that increased work load”

The Platino Fiber laser can be used to cut a wide range of materials. Fiber lasers are more effective than other laser sources for cutting highly-reflective materials (e.g. aluminum alloys, copper, brass). The Platino Fiber cuts various thicknesses, up to 20 mm of mild steel, with efficiency and quality. Productivity increases particularly with thin and medium-gauge sheet metal.

"A major reason for choosing the Prima Power Platino Fiber laser was its cantilever design - says Muns - All the other lasers were gantry design. We have many cases where we process oversized sheets by cutting one half and then flipping it around and picking up reference points and cutting the other half. And that was one of the deciding factors in choosing the Prima Power cantilever design"

Eliminating Secondary Operations

“The Platino Fiber laser also removed all the secondary operations that we had to do with the punch presses - adds Ogun Unal, manufacturing & mechanical engineer - Because of the micro joints used with the punch presses, it took up valuable time to remove the parts from the sheets. With the laser, we can modify the micro joint thicknesses that saves us a lot of time. We also took advantage of the nesting to utilize more of the sheet and we used some functions like common-line cutting that left no burr that had to be removed.”

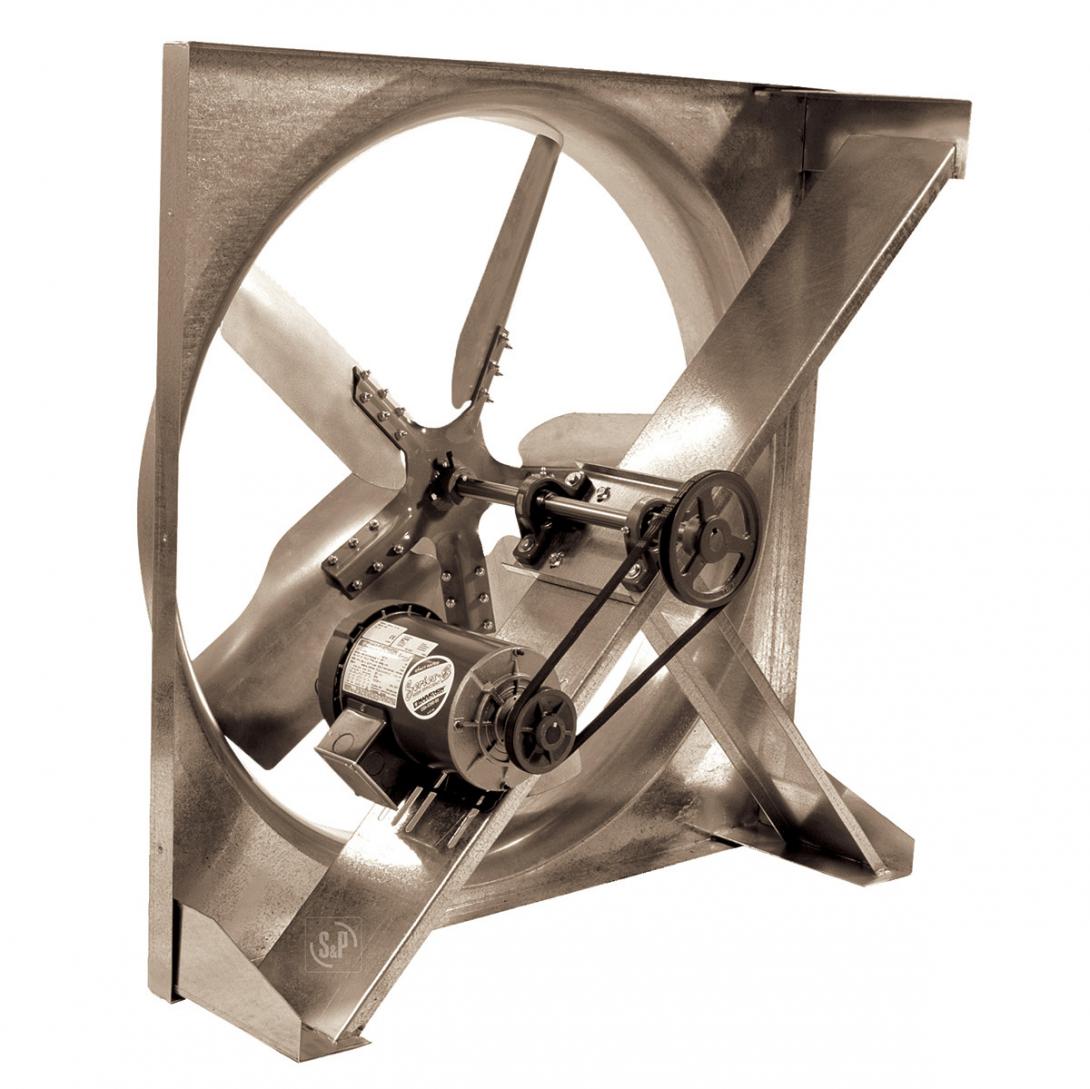

"Before the laser, in order to produce the vanes for the centrifugal fans, we would shear a strip, run it through a blank die, and then run it through the form die - adds Muns - Now all we have to do is cut the blanks with the laser and run it through the form dies. We’ve eliminated all those different operations, which of course go right to the bottom line. The same is true with our propeller blades which we originally outsourced. We would get these blanked and go through a forming operation and then a piercing operation. Now we just laser cut the blanks

with the holes in them and then form them...and we’re done. We’ve eliminated a lot of die operations."

Flexible Automation

S&P also purchased a 15-shelf Compact Tower with the Platino Fiber laser. The tower allows easy loading/unloading for blanks and processed sheets. It has an elevator for loading and unloading the pallets on and off the tower, and features single sheet separating, control systems, and sheet reference. The Platino Fiber is particularly suitable for lights-out operation, often performed in unattended mode. It is a fully independent machine, with no need for manual intervention during machine operation. Once the production schedule is programmed, the Platino Fiber laser takes care of the necessary settings, tip replacement, sheet change and storage, etc.

“As we adapted to automation, instead of just running the laser first and second shifts, we were able to program the laser to run lights out because of the tower.”