Robotics Integration Solutions

MATERIAL HANDLING SOLUTIONS

Free your potential with a complete all-in-one partner

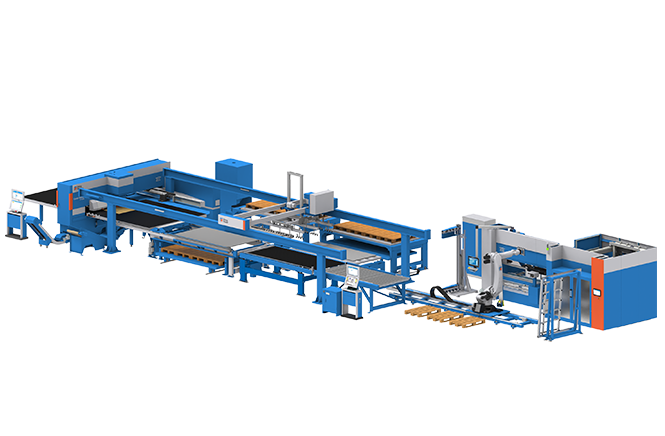

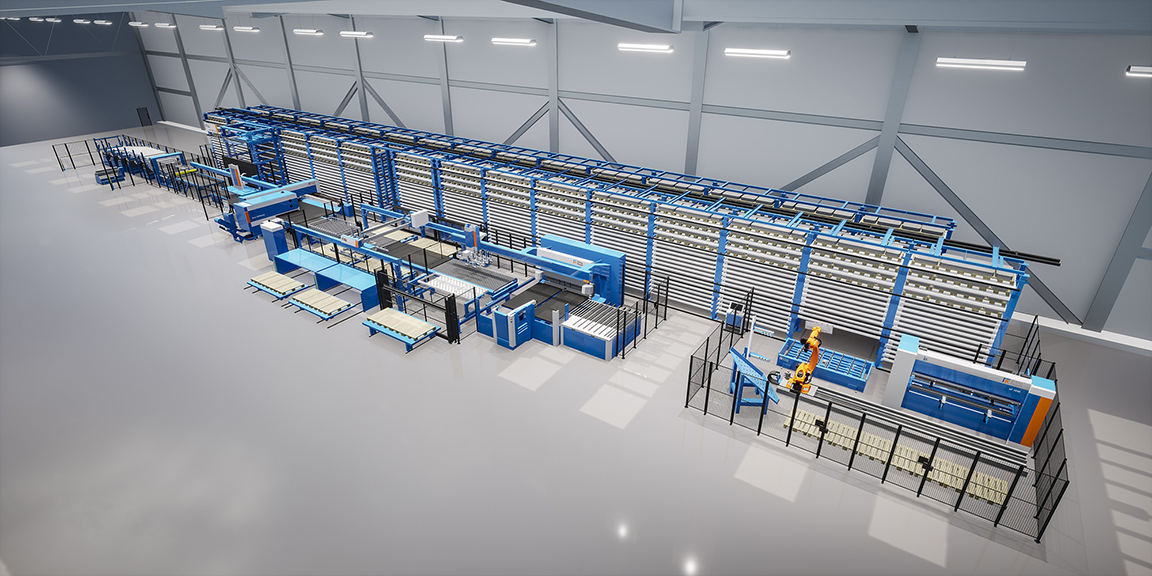

Complete solutions from coil to assembly combined with the widest range of modular machines: 2D/3D laser cutting, punching & shearing, bending and FMS.

Internal Robotics Integration Unit born from the specialized expertise of long-time partner Sistec AM, now part of the group.

Full performance optimization: in-house engineering prompts complete robot-machine synergy and smart handling.

Process-oriented approach simplify and optimize production flow through advanced robotics integration and modular automation.

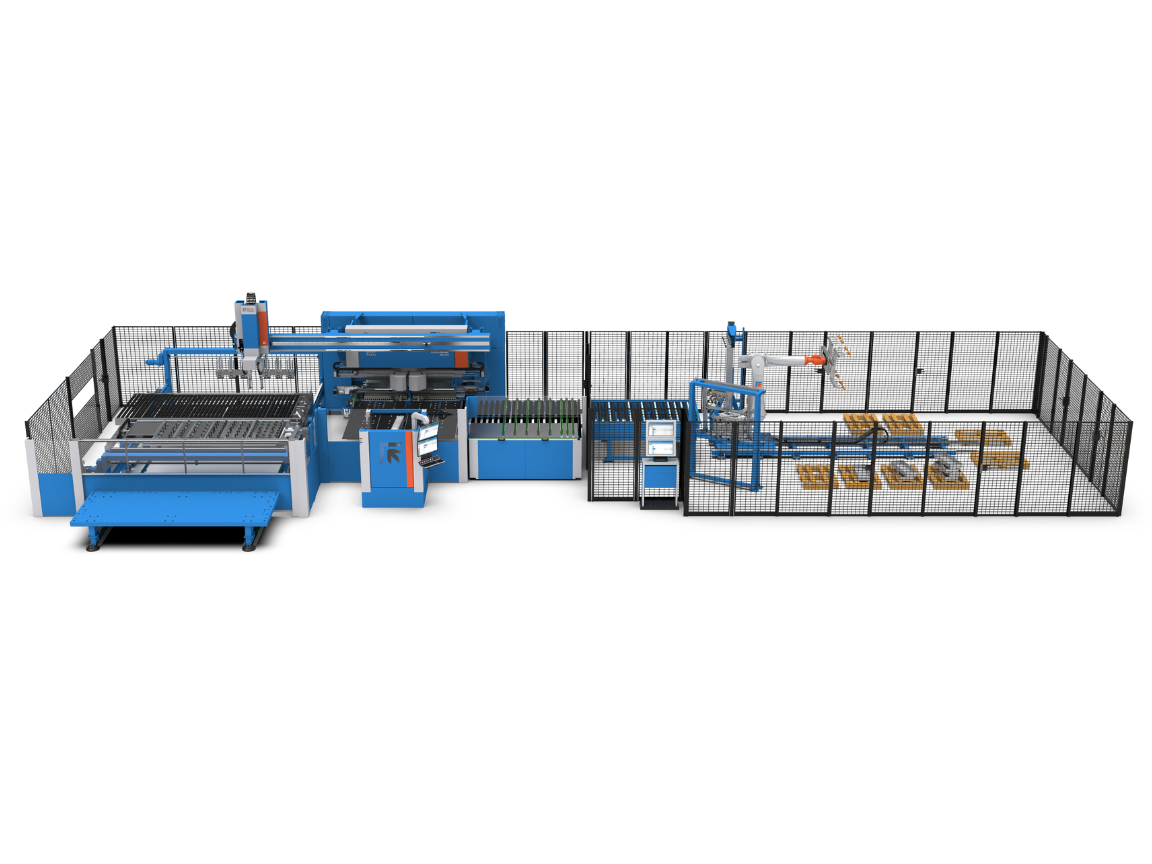

Robotics integration is the key to unlocking greater efficiency, flexibility, and productivity in sheet metal manufacturing. By seamlessly combining industrial anthropomorphic robots with a wider range of technologies into robotic cells or complete Flexible Manufacturing Systems, Prima Power's solutions optimize every stage of production, from material handling to assembly, while ensuring a compact, scalable, and high-performing system design.

Sheet metal manufacturers can now free their potential with all-in-one modular and scalable solutions, from a single partner with a dedicated Robotics Integration Unit. These solutions allow manufacturers to streamline production flow, reduce cycle times, and improve overall output.

Whether enhancing standalone machines or building fully automated FMS, Robotics Integration Solutions provide a future-proof approach to manufacturing automation.

Designed to meet the diverse needs of OEMs and job shops of any size, Prima Power’s Robotics Integration Solutions offer:

Fully integrated automation for material handling, e.g. loading/unloading, picking and sorting, part transfer, and added processes such as welding, assembly, etc. – all in one partner

Flexible and modular configurations to adapt to evolving production demands

Smarter workforce utilization, reducing manual operations, increasing productivity and accuracy and reducing wastes

Optimized layouts that reduce footprint and simplify integration into the factory while enhancing efficiency.

Related technologies

Take a look at the other products and choose the best solution

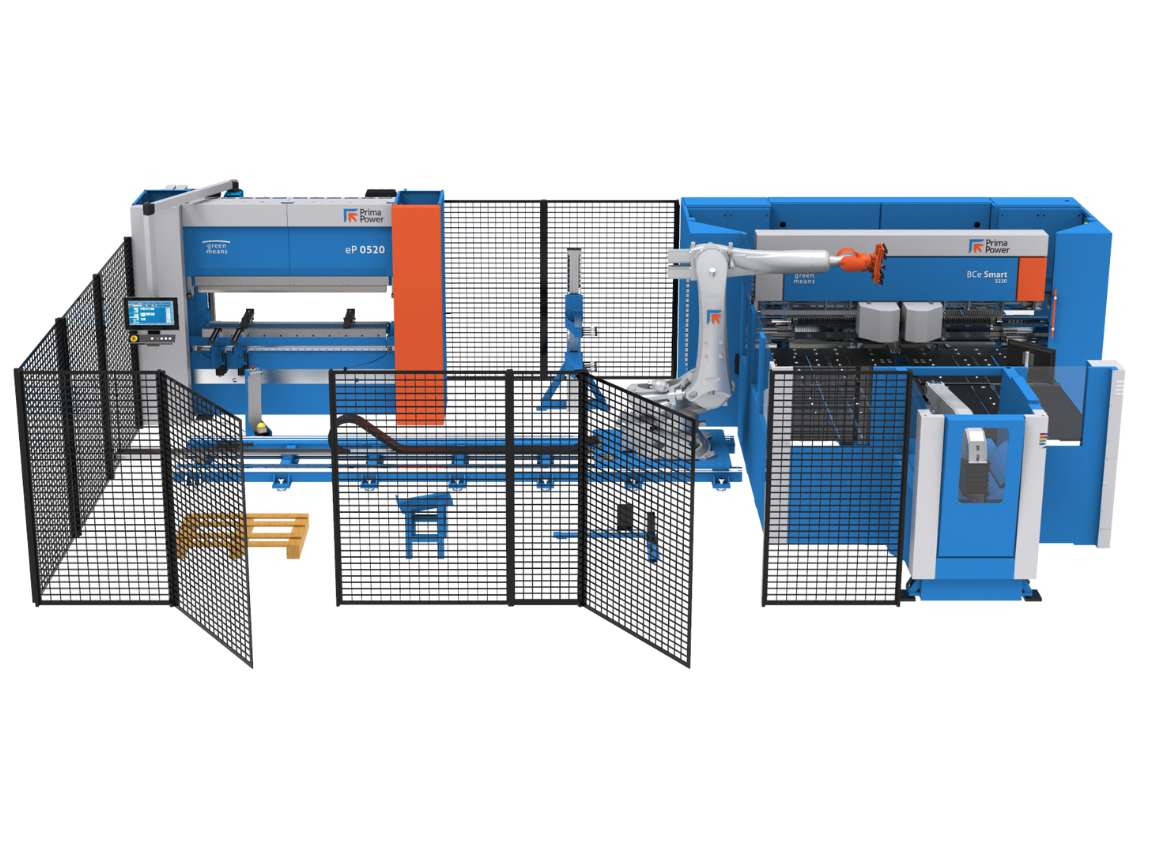

Robotic Bending Cells

ROBOTIC BENDING CELLS

Full performance optimization into your arms

Loading and stacking robot (LST)

MATERIAL HANDLING

A high-performance automatic loading and stacking robot

Compact Server

MATERIAL HANDLING

Automatic loading and unloading device for raw material and processed sheets for 2D laser machines

Loading and stacking robot (LSR)

MATERIAL HANDLING

A material and part handling robot for punching machines and laser-punch combined machines

Material loading and unloading device (Compact Express)

MATERIAL HANDLING

Entry level solution to automate material handling

Unloading device Compact (UDC)

MATERIAL HANDLING

A compact solution for skeleton and micro-jointed part unloading

Connection to automatic bending

MATERIAL HANDLING

Direct connection to Express Bender for part bending

Easy sorting table

MATERIAL HANDLING

An entry-level sorting solution for punch-shear combined machines

Picking and stacking robot (PSR)

MATERIAL HANDLING

The clever and flexible picking and stacking robot

Sheared part buffering (SPB)

MATERIAL HANDLING

Sheared part buffering (SPB)

Cut-to-length

MATERIAL HANDLING

High productivity and flexibility with money savings

Sheared part sorting conveyor (C1500)

MATERIAL HANDLING

Automatic sorting of small sheared parts

Sheared part stacking system (STS)

MATERIAL HANDLING

A high capacity stacking solution for sheared parts

Third pallet station

MATERIAL HANDLING