eP Series

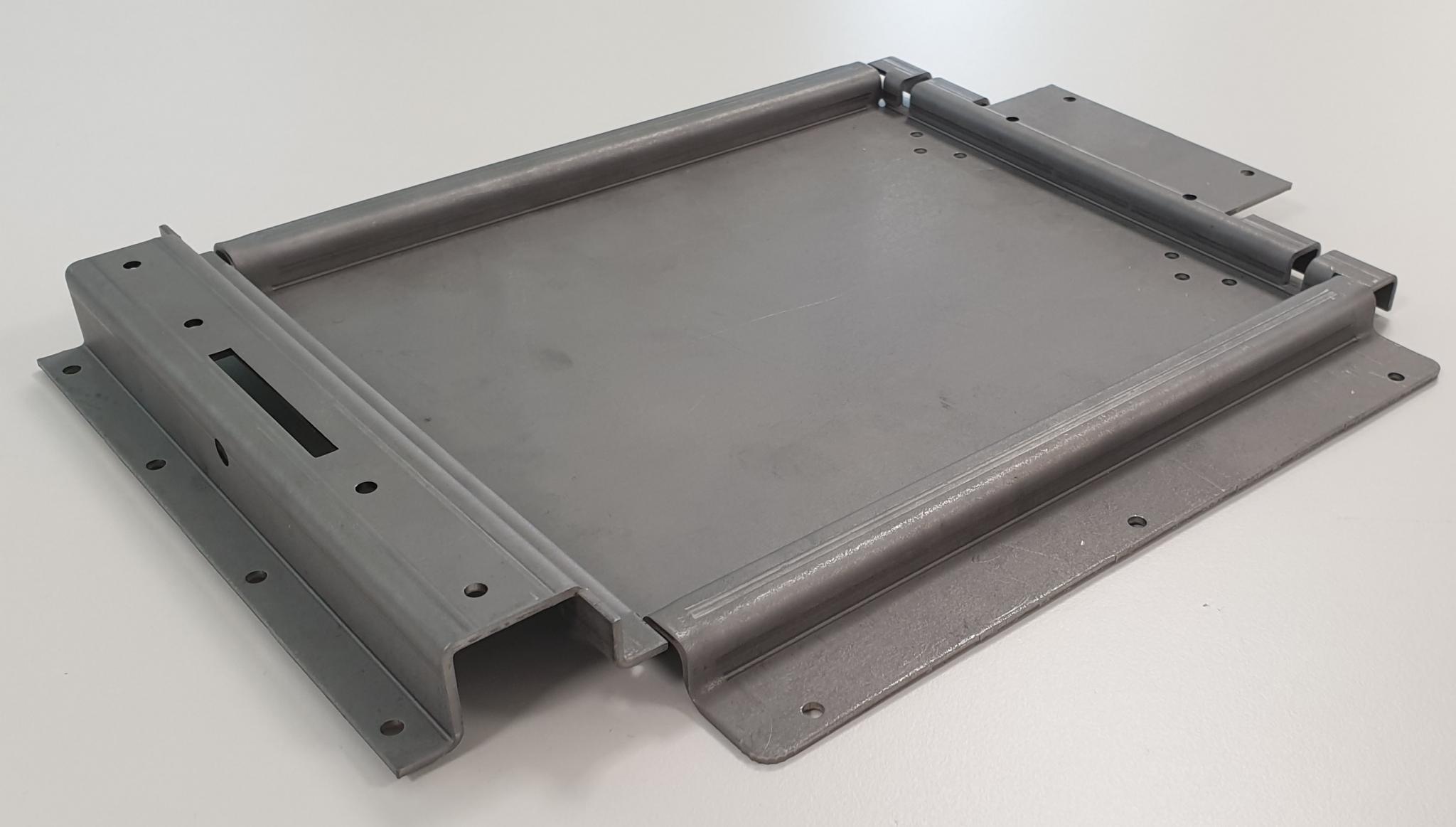

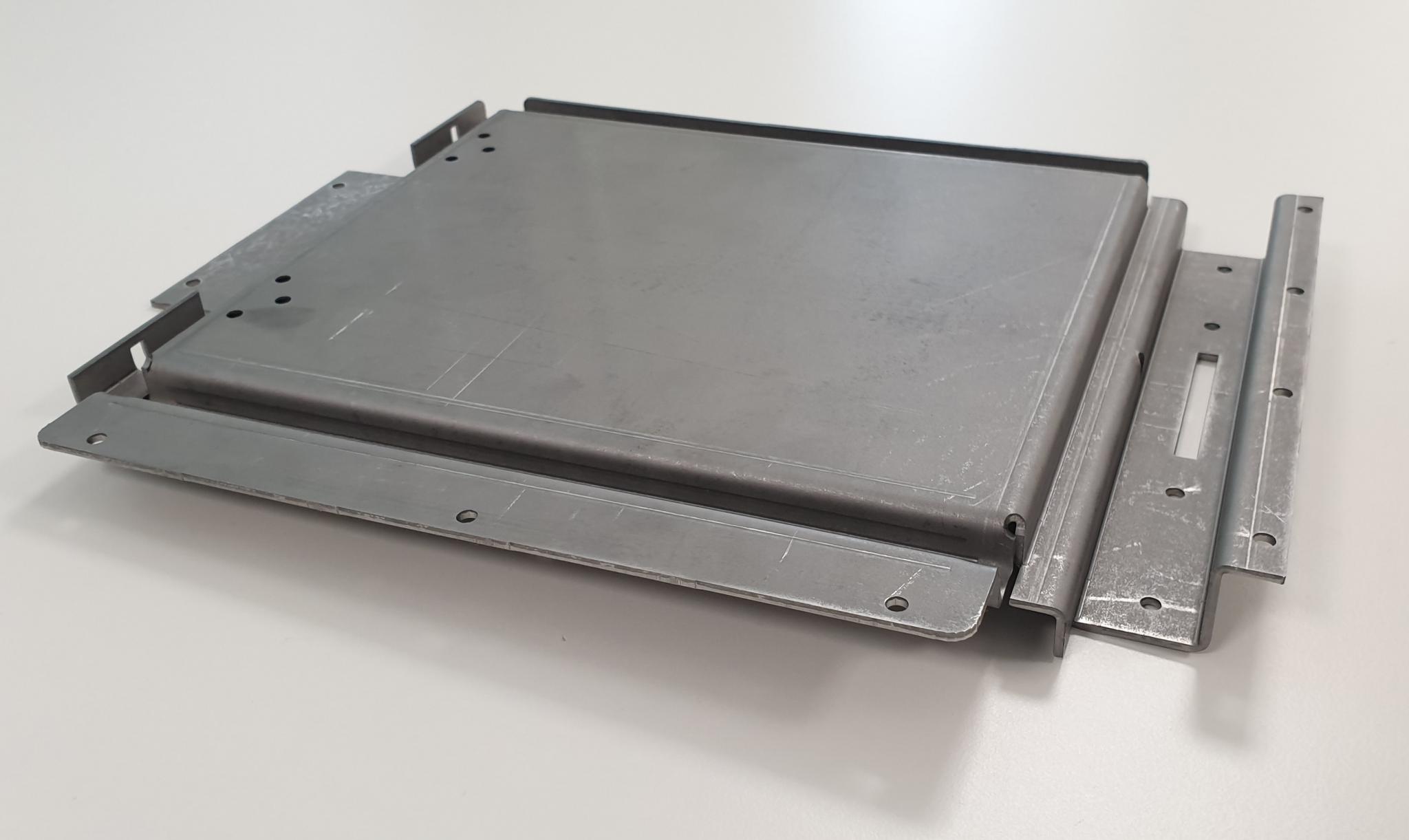

PRESS BRAKES

High reliability and maximum productivity

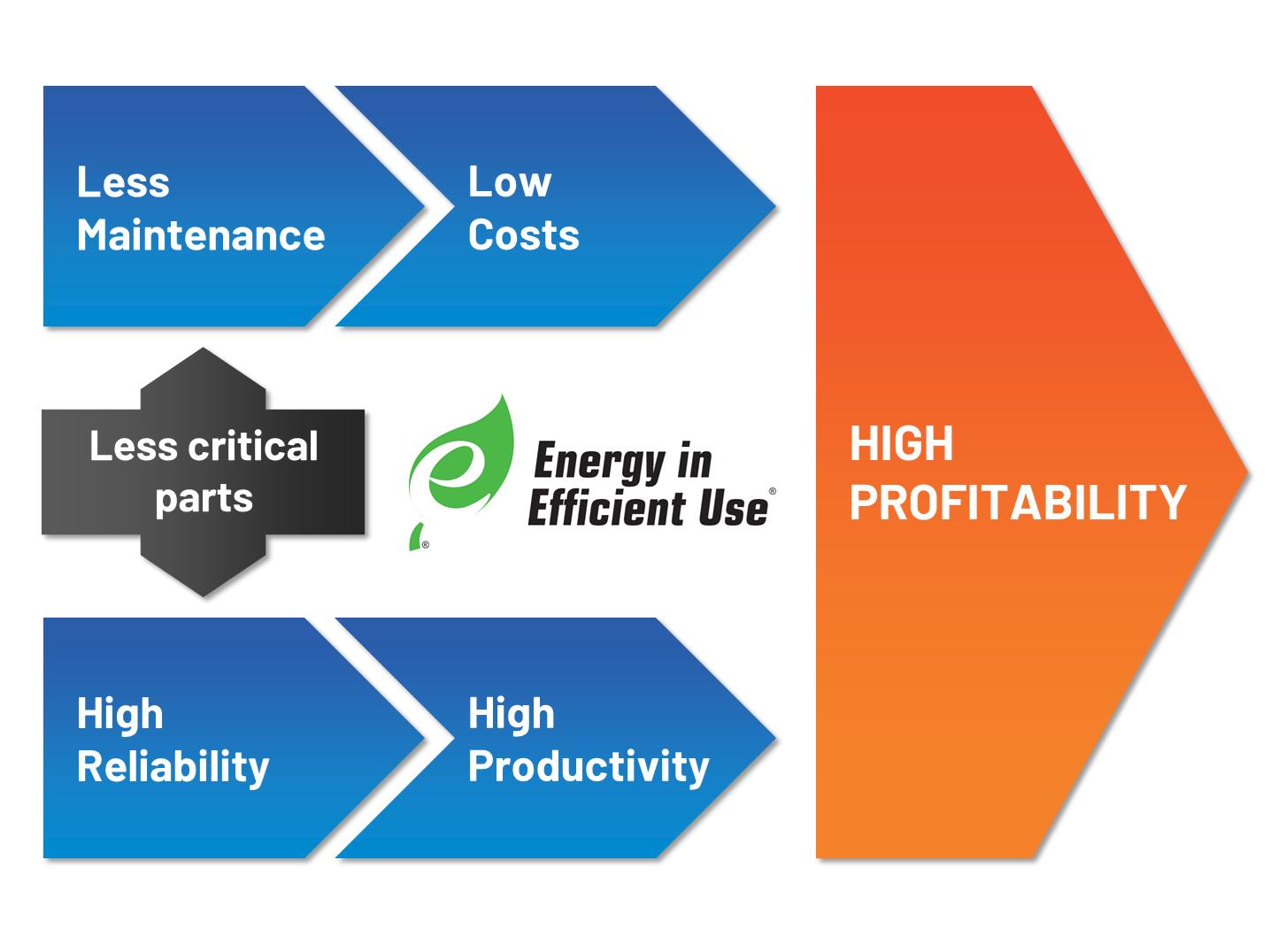

ENERGY EFFICIENT

Less energy required and lower environmental impact.

PRODUCTIVE

High productivity due to reduced cycle times and higher process reliability.

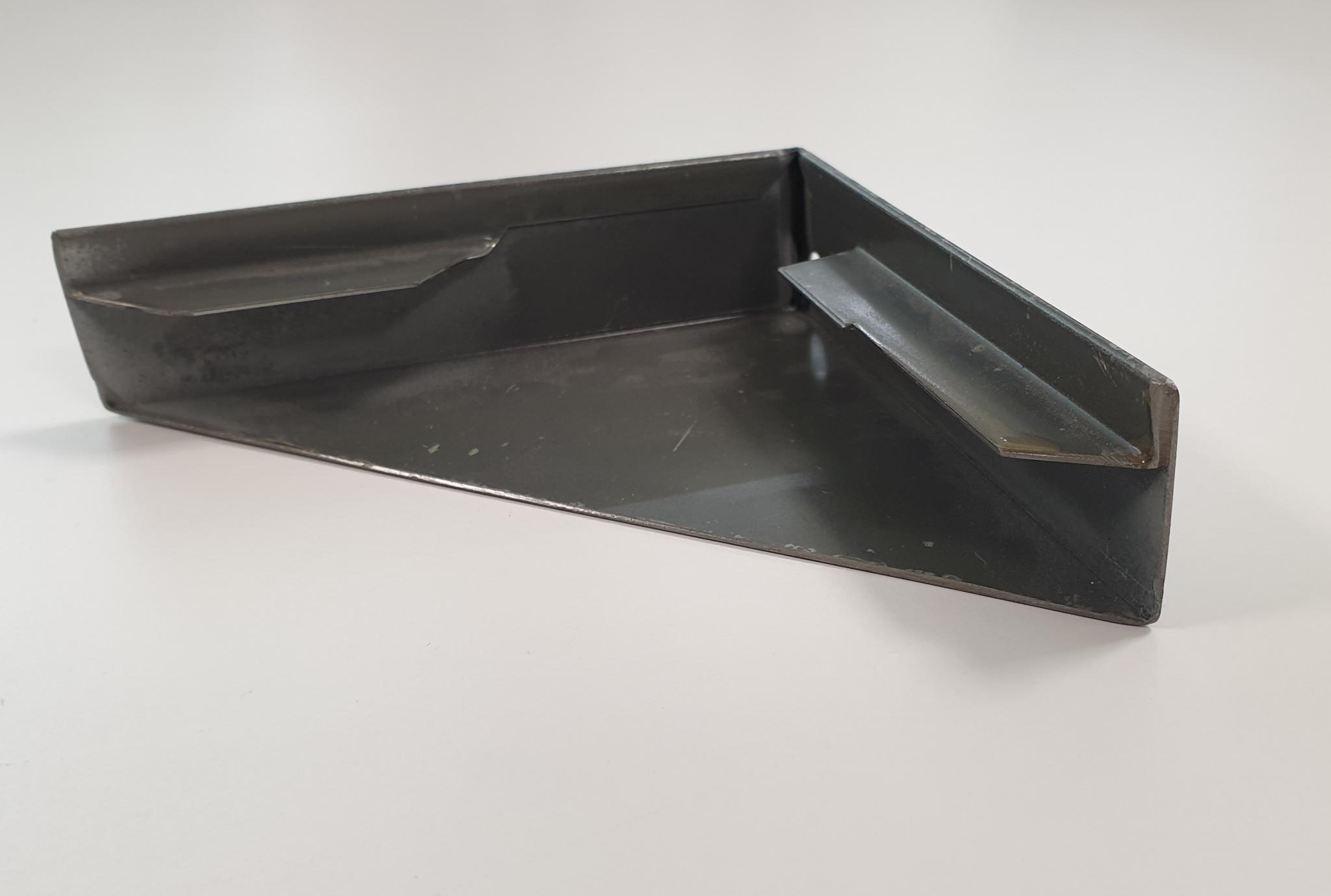

MODULAR

Capable of meeting any production need, with a variety of possible configurations to meet different products.

USER FRIENDLY

Easy to install, use and maintain.

With more than 20 years of experience in applying servo electronics in sheet metal working, eP-series press brakes meet the requirements of the most exigent customers for the machining of medium-thin metal sheets.

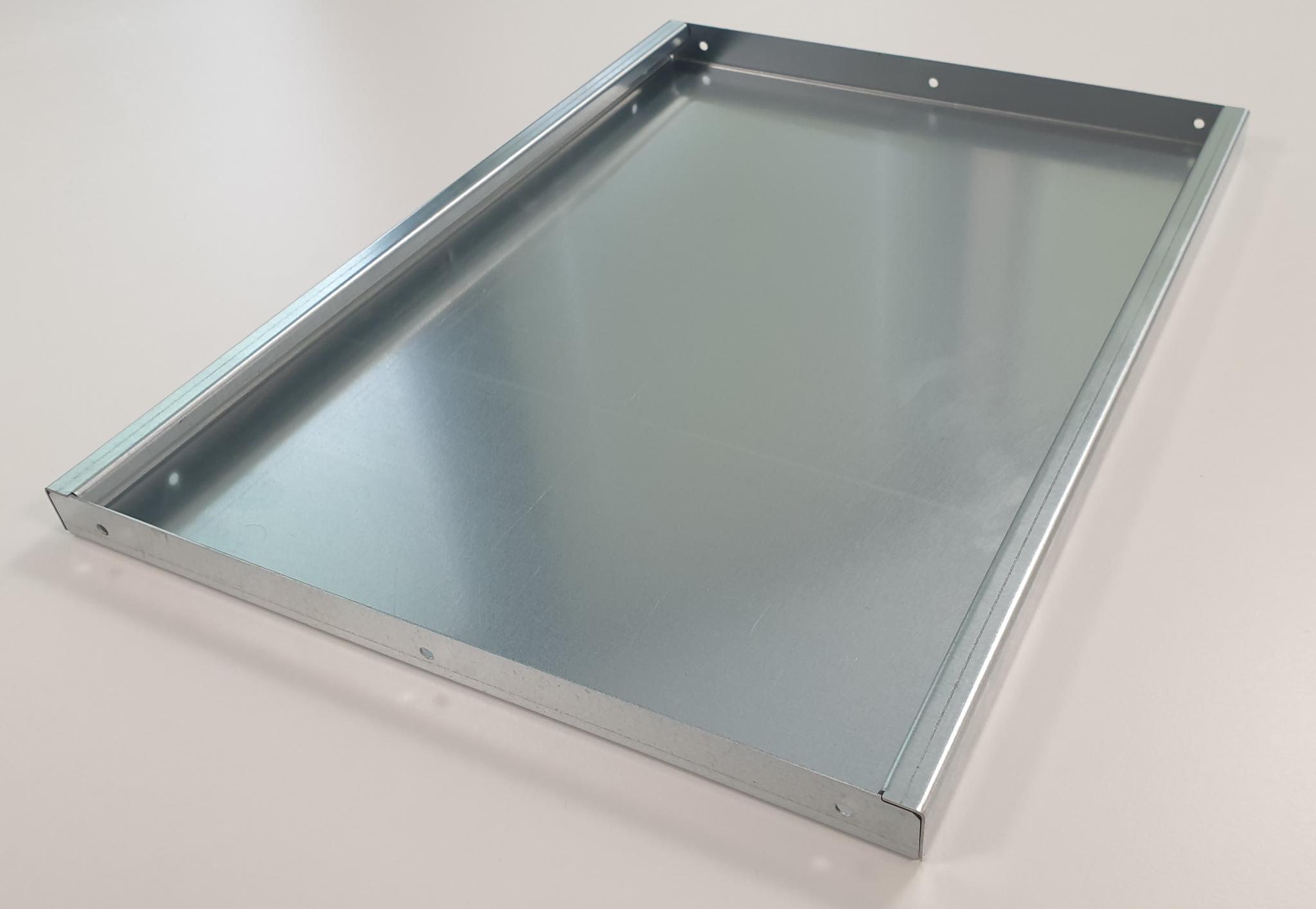

This is the reason why Prima Power eP-series is the optimal solution for manufacturers of HVAC, metal furnitures, white goods and domestic appliances, facades, electrical cabinets and all those applications that need a fast and accurate machine to increase the productivity.

The servo-electric concept combines productivity, accuracy, flexibility and reliability with high respect to ecological aspects – we call this concept “Green Means®”.

The concept offers you both sustainability and manufacturing efficiency and productivity. It means greater versatility, lower power consumption, less maintenance and no oil to purchase or to get rid of. In addition, easy programming and outstanding accuracy eliminate waste production. You simply make better sheet metal components at lower cost.

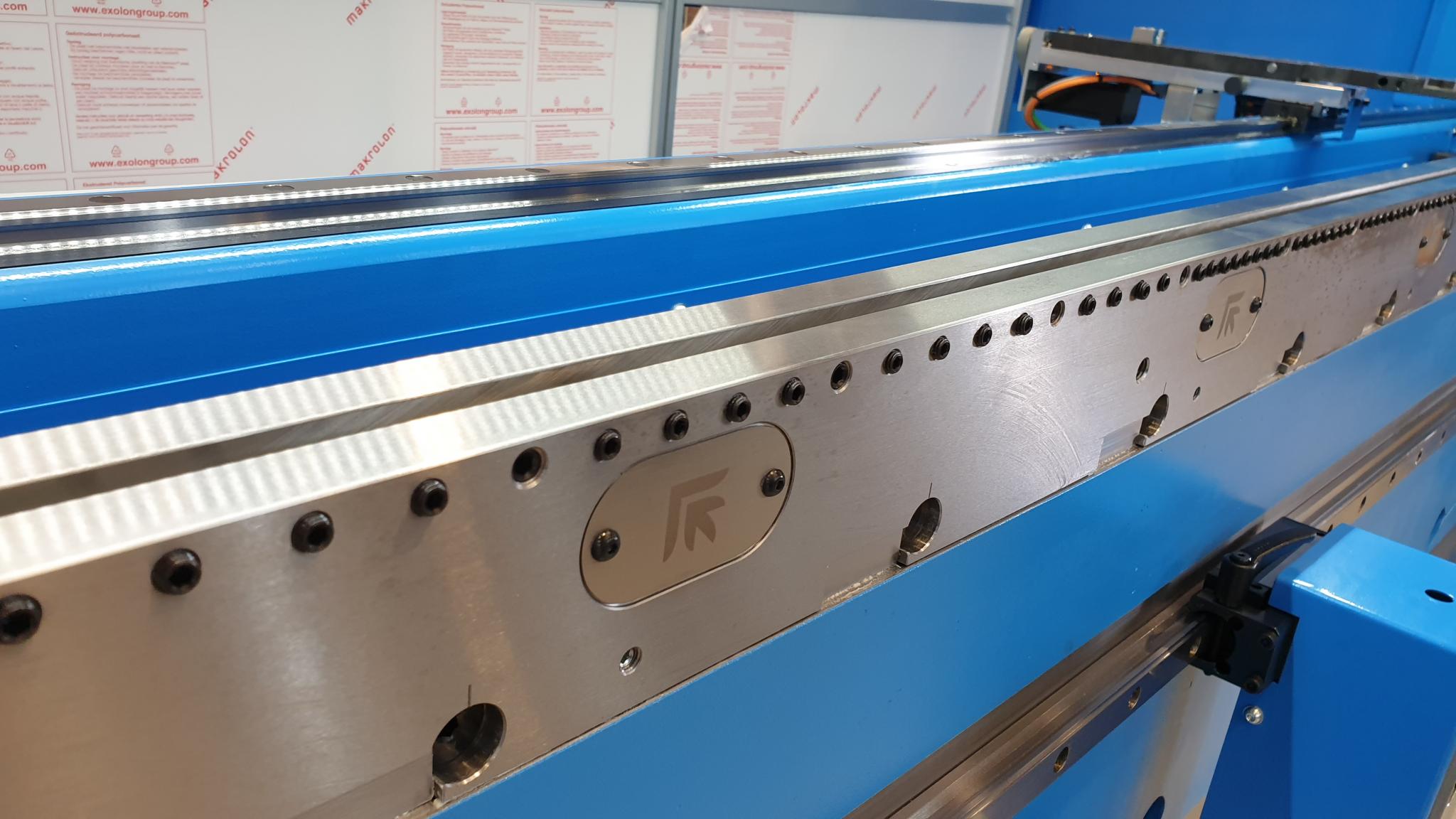

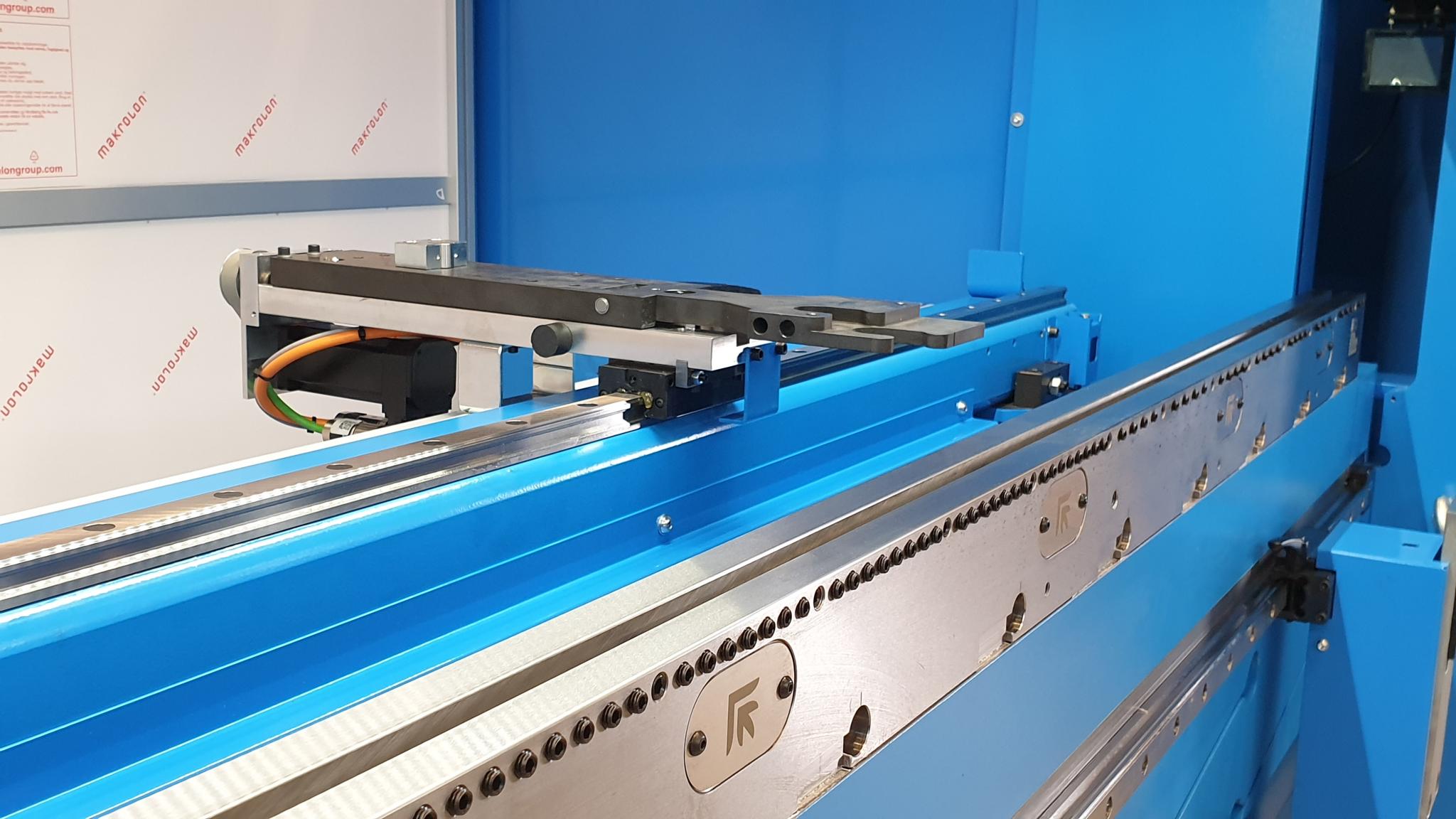

The eP-Press features the advantages of high acceleration, deceleration and fast response times of the servo-electric drive system.

Compared to conventional press brakes, considerable productivity increase can be reached thanks to reduction of cycle times by up to 30% and more.

Working speed is programmable to ensure bending is made without loss of product quality or operator safety.

Lazer Safe IRIS System provides safe high speed by closing down almost at the metal sheet level.

From 55 ton to 200 ton

From 2000 mm to 4000 mm

Optimize your Prima Power machine

AutoPol BendSim

MACHINE PROGRAMMING

Easy-to-use and effective tool for off-line programming of all Prima Power P series brakes.

Related technologies

RELATED AUTOMATION

Robotic Bending Cells

ROBOTIC BENDING CELLS

Full performance optimization into your arms

SUCCESS STORIES

Find out how a Prima Power eP series machine took part in a company's success

Silicon Valley Job Shop Achieves Success with Prima Power Machines

Since A & J Precision Sheetmetal Inc., San Jose, CA, first opened its doors in 1995, the company has earned a stellar reputation as a leading job shop producing high-quality precision parts in the demanding Silicon Valley.

Order and efficiency drive productivity, from first cut to finished product

Astra was founded just short of thirty years ago as the result of an innovative instinct which proved successful in just a few years: that stainless steel would become the technological material of the future.

Flexibility and precision in the manufacture of custom rack cabinets

After having chosen Prima Power as the supplier of the company's very first laser cutting machine, ATP decided to continue focusing on the quality and technology of the Italian manufacturer by also investing in a servo-electric bending machine

Facing Adversity and Winning with Prima Power Equipment

How many job shops could lose a customer that accounted for 98% of their business and recover in just a few years? Elm Machining was faced with that scenario several years ago.

Snow- and ice-free roads even faster now

After about thirty years, Giletta, a company that is part of the Bucher Municipal group, a landmark in the production and sale of snow removal machines and equipment, decided to bring the steelwork department back in-house by installing a new fiber laser cutting system and a servo-electric press brake both by Prima Power.

Riding the Night Train to Higher Productivity

The Minerva Group in Bologna, Italy is a company that truly embodies skills, technology, and entrepreneurial spirit.

A look at the technology behind turnkey organic poultry plants

SKA srl manufactures poultry systems for organic free-range farming with high levels of product customisation by taking advantage of innovative Prima Power technology.