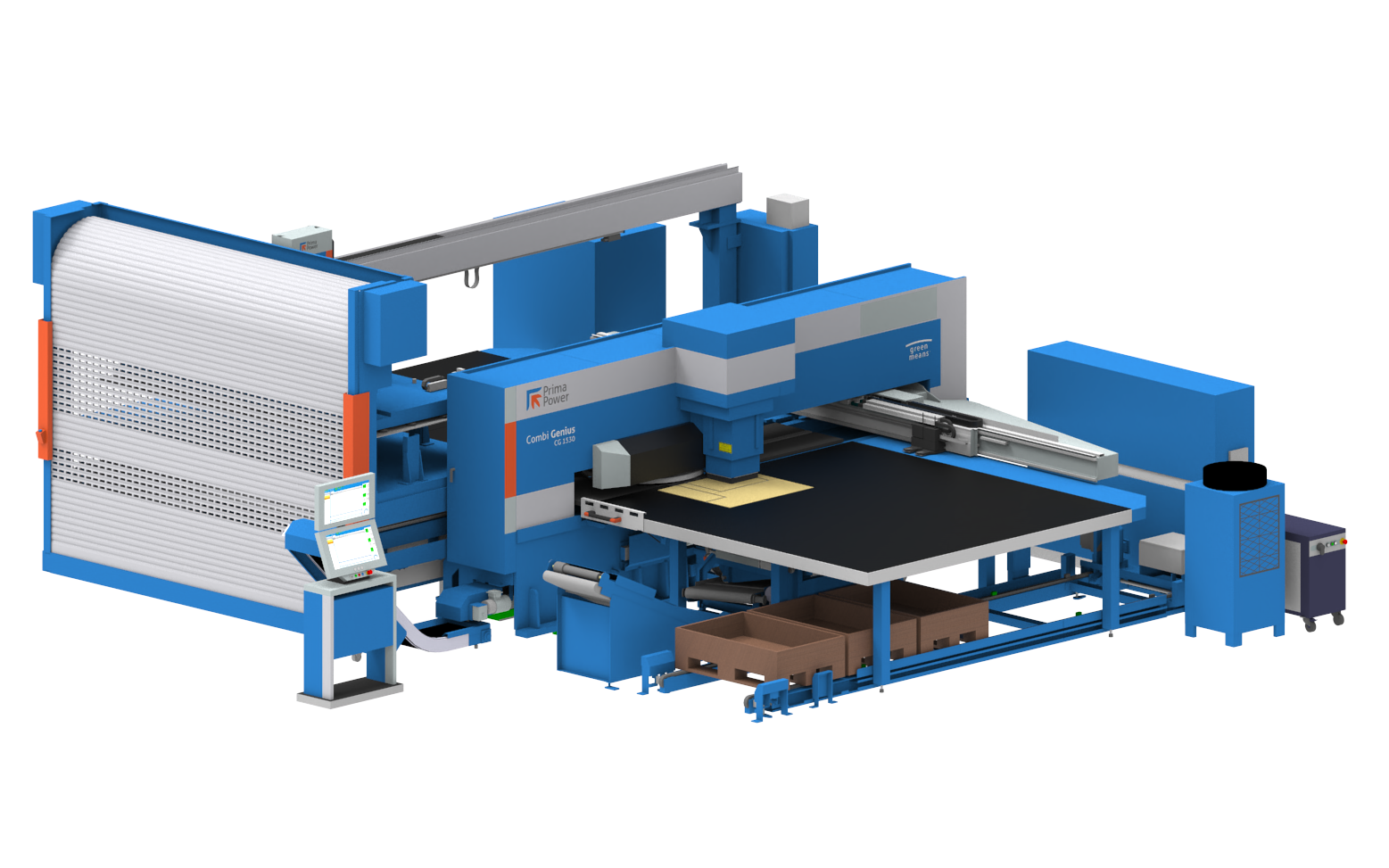

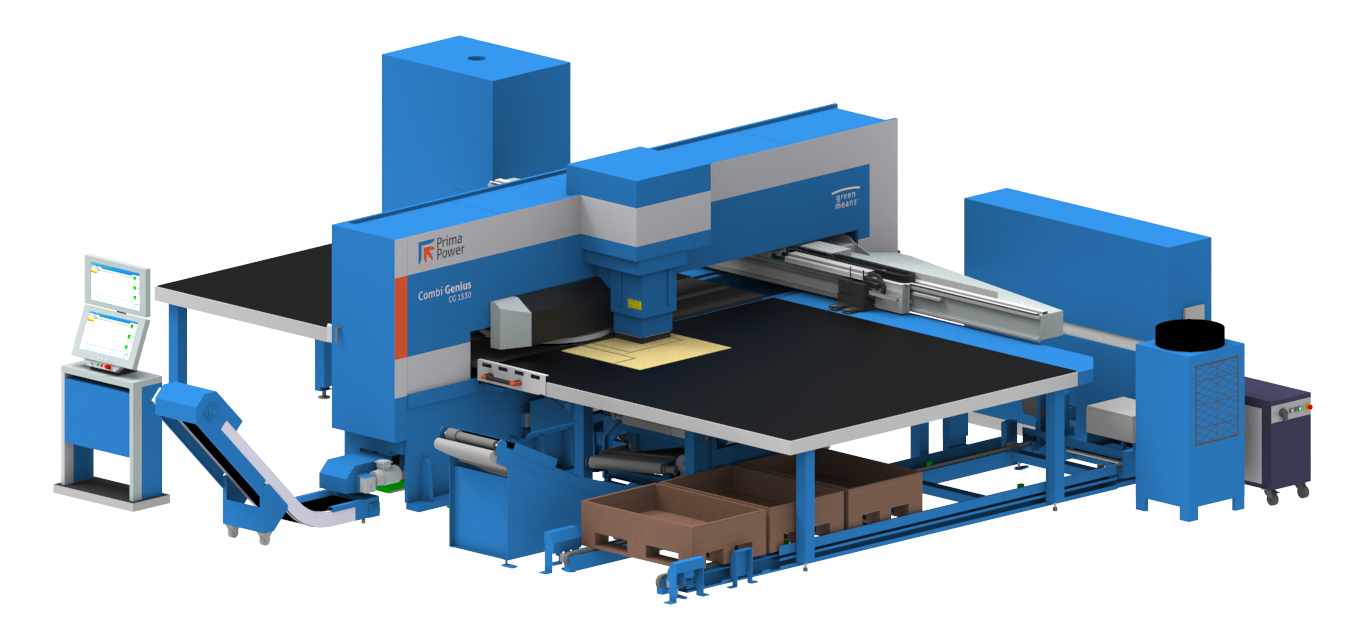

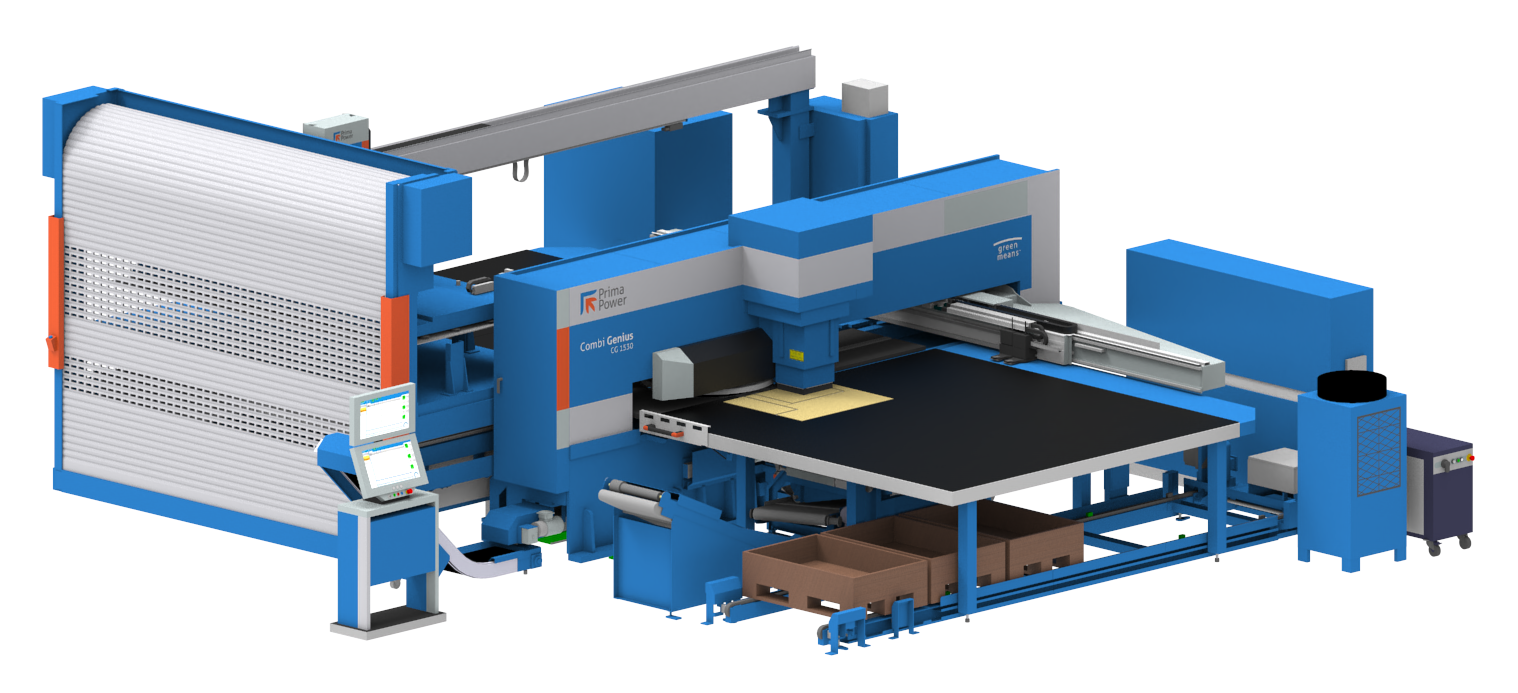

Combi Genius

PUNCHING AND LASER CUTTING COMBINED MACHINES

Punching + Laser cutting = Superior manufacturing economy

1+1>2

HIGH TOOLING CAPACITY

Customized turret design allows up to 400 standard or 384 index tools for active use.

COMPACT LAYOUT

Small floor space needed.

MODULAR TECHNOLOGY

Manufacturing cell can be equipped with automation solutions to achieve unattended production.

ECONOMICAL MANUFACTURING

3, 4 or 6 kW Prima Power fiber laser resonator offers economical manufacturing capacity for a large range of sheet metal products.

Punching and Laser cutting combined machine is unbeatable when it comes to versatility and flexibility, combining multiple operations in one machine. This Lean Manufacturing style reduces cost per part; parts will be made fast,easily and accurately through one machine by one operator using only one operating and programming system.

The Combi machine works with numerically controlled, servo-electric axes, providing high speed operations, low maintenance requirement, superior energy efficiency and lower production costs.

A high brilliance fiber laser is integrated into the Combi Genius enabling manufacturing faster, more economically and with a wider range of materials than any alternative solution on the market.

Prima Power's ECOPUNCH® concept is an astonishing money saver in terms of energy consumption. Compared to traditional method Prima Power can produce more parts at same energy.

The control panel is integrated in the electric cabinet for easy cabinet placing and easy access to machine controls. This versatile control allows work preparation, program background editing and set up while the machine is running.

The optimized cutting head, collimator, delivery fibre and cutting parameters guarantee the highest cutting quality and speed for the Prima Power combi machine in the market.

23 ton and 30 ton punching force as standard, depending on selected performance (Pure/Dynamic).

Up to 400 standard or 384 index tools can be simultaneously available in the turret for active use.

TOOLING

The large number of tools with Prima Power punching machines results from a set of technical features which is not available from any other manufacturer:

• Two turret construction alternatives: 16 and 20 stations

• Multi-Tools®

• A vast variety of special tools

• Rotating Auto-Index system

• Intelligent ram

The Punch Laser combination equipped with servo-electric punching provides both fast nibbling speeds and the possibility of using low ram speeds when employing forming tools or for reducing the noise level with large-diameter tools. The fully programmable stroke length gives a variety of possibilities in forming operations, all the way up to bending.

Two models: CG1530 and CG1540

- Max sheet size CG1530: 3,000 mm x 1,500 mm CG1540: 4,300 mm x 1,500 mm

- Max. sheet thickness: 8 mm

- Customized turret. Max. tools in turret: 400

- Max. index tools in turret: 384

- Laser power: 3 kW, 4 kW or 6 kW

- Max. sheet thickness, punch and laser: 8 mm (Al, Mild steel, Stainless steel)

Two performance levels: Pure and Dynamic

The new Genius series has models on two complementary performance levels. Pure meets all the targets set for an attractively priced, yet efficient production machine; Dynamic offers the best productivity and performance in the market. Both models come with the latest features and can be equipped with the whole range of options.

- Ram force, max. CG Pure: 230 kN (25 US Tons) CG Dynamic: 300 kN (33 US Tons)

- Hit speed, max. CG Pure: 700 hpm CG Dynamic: 1,000 hpm

- Positioning speed CG Pure: 127 m/min CG Dynamic: 150 m/min

- Index tool rotation speed CG Pure: 180 rpm CG Dynamic: 250 rpm

Optimize your Prima Power machine

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Tulus Analytics

PRODUCTION REPORTING AND MONITORING

Parts production and machine performance reporting

Related technologies

RELATED AUTOMATIONS

Loading and stacking robot (LST)

MATERIAL HANDLING

A high-performance automatic loading and stacking robot

Loading and stacking robot (LSR)

MATERIAL HANDLING

A material and part handling robot for punching machines and laser-punch combined machines

Material loading and unloading device (Compact Express)

MATERIAL HANDLING

Entry level solution to automate material handling

Unloading device Compact (UDC)

MATERIAL HANDLING

A compact solution for skeleton and micro-jointed part unloading

Connection to automatic bending

MATERIAL HANDLING

Direct connection to Express Bender for part bending

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

Take a look at the other products and choose the best solution

Combi Sharp

PUNCHING AND LASER CUTTING COMBINED MACHINES

Integrated punching and laser cutting at an affordable price

SUCCESS STORIES

Find out how a Prima Power Combi Genius machine took part in a company's success

Silicon Valley Job Shop Achieves Success with Prima Power Machines

Since A & J Precision Sheetmetal Inc., San Jose, CA, first opened its doors in 1995, the company has earned a stellar reputation as a leading job shop producing high-quality precision parts in the demanding Silicon Valley.

Future fit with the punch laser machine

Eisenwerk Wittigsthal GmbH invests in a punch-laser system so as to be ready for the digital future.

Riding the Night Train to Higher Productivity

The Minerva Group in Bologna, Italy is a company that truly embodies skills, technology, and entrepreneurial spirit.