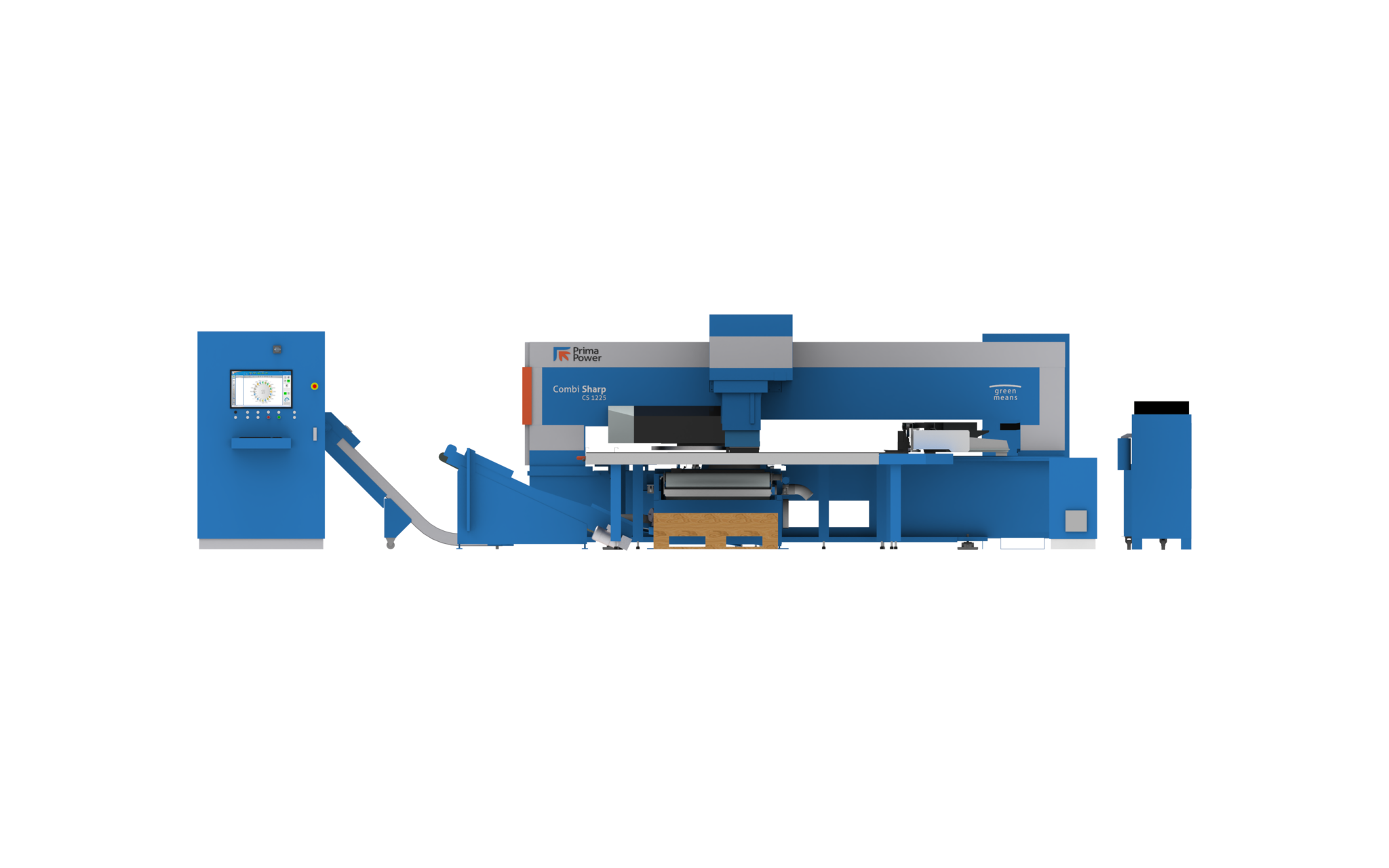

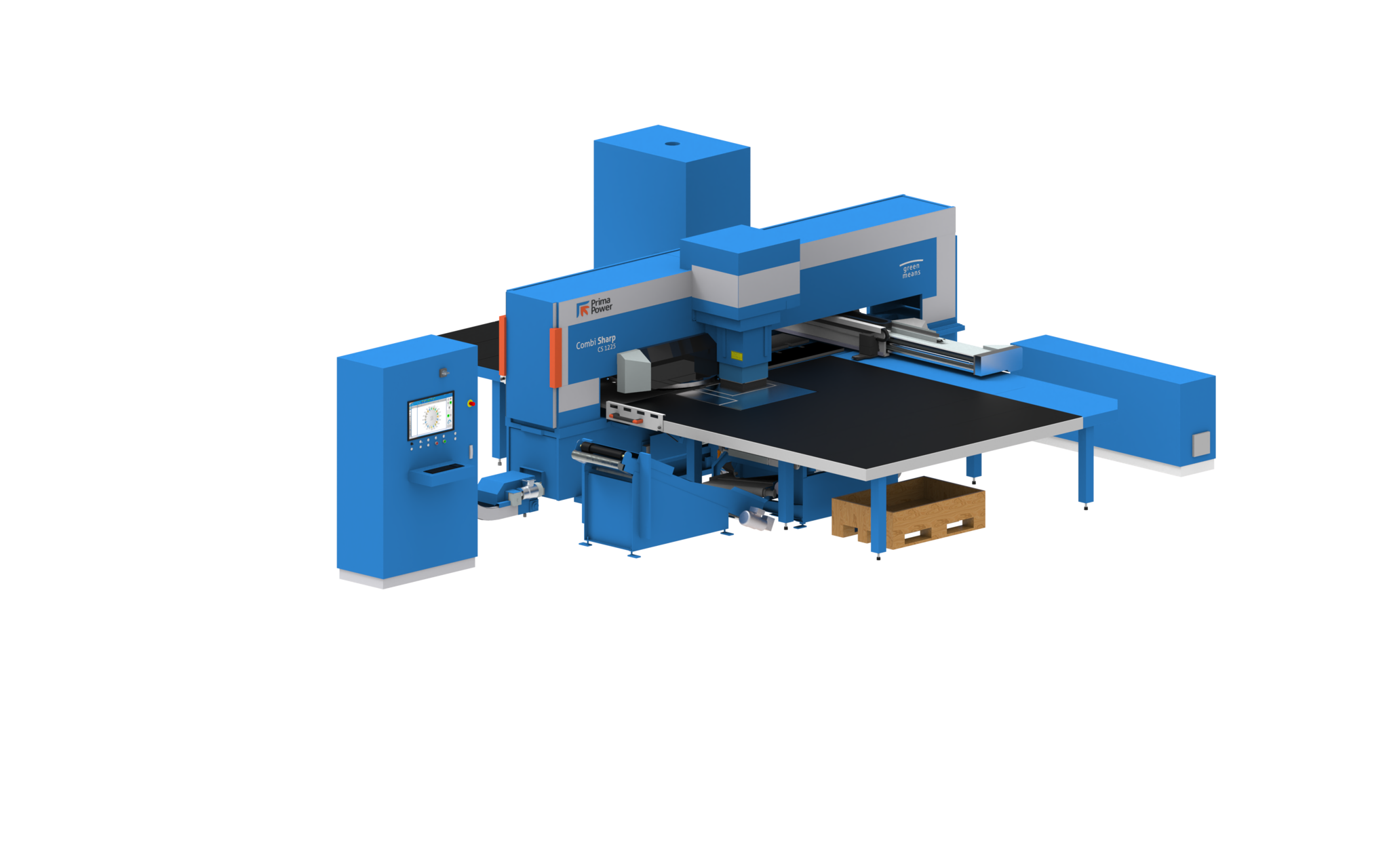

Combi Sharp

PUNCHING AND LASER CUTTING COMBINED MACHINES

Integrated punching and laser cutting at an affordable price

FABULOUS FIVE

Punching, forming, marking, bending, laser cutting - all in one.

HIGH PRODUCTIVITY

High speeds, ease of operation, minimum set up times.

COMPACT LAYOUT

Small floor space needed even with automation modules.

LOW ENERGY CONSUMPTION

Servo-electric punching and fiber laser cutting technologies, no laser gas required

HIGH TOOLING CAPACITY

Customized turret design allows up to 384 standard or 128 index tools for active use.

Combi Sharp is a compact punching and fiber laser cutting cell with high accessibility. Two resonator alternatives and large tooling capacity offer superior productivity at a profitable price. The optimized cutting head, collimator, transfer fiber and cutting parameters ensure a very high cutting quality up to 8 mm material thickness.

Modularity is power

In the core of the machine is Punch Sharp, a modular solution to grow to a combi machine also afterwards if your production directs towards more complex parts.

Easy cover protection system

New safety system allows easy access to the machine, manual loading of sheet and unloading of large parts and skeleton is convenient to perform.

The control panel is integrated in the electric cabinet for easy cabinet placing and easy access to machine controls. This versatile control allows work preparation, program background editing and set up while the machine is running.

TOOLING

The large number of tools with Prima Power punching machines results from a set of technical features which is not available from any other manufacturer:

• Two turret construction alternatives: 16 and 20 stations

• Multi-Tools®

• A vast variety of special tools

• Rotating Auto-Index system

The Punch Laser combination equipped with servo-electric punching provides both fast nibbling speeds and the possibility of using low ram speeds when employing forming tools or for reducing the noise level with large-diameter tools. The fully programmable stroke length gives a variety of possibilities in forming operations, all the way up to bending.

The optimized cutting head, collimator, delivery fibre and cutting parameters guarantee the highest cutting quality and speed in the market for the Prima Power combi machine. The high-quality fibre lasers are available with two cutting powers, 3 and 4 kW.

Combi Sharp CS1225

- Max sheet size 2,500 mm x 1,250 mm

- Ram force: 230 kN (25 US Tons)

- Hit speed: 700 hpm

- Positioning speed: 108 m/min

- Index tool rotation speed: 166 rpm

- Standard turret: 20 stations; 250 tools (4 index, 35 tools)

- Fiber laser power: 3 or 4 kW

- Max. sheet thickness, punch and laser: 8 mm (Aluminium, Mild steel, Stainless steel)

- Max sheet weight: 200 kg

- Average power consumption: 3.2 kW (punch) 8 kW (YLS-3000) 9 kW (YLS-4000)

Optimize your Prima Power machine

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Related technologies

RELATED AUTOMATIONS

Loading and stacking robot (LST)

MATERIAL HANDLING

A high-performance automatic loading and stacking robot

Material loading and unloading device (Compact Express)

MATERIAL HANDLING

Entry level solution to automate material handling

Unloading device Compact (UDC)

MATERIAL HANDLING

A compact solution for skeleton and micro-jointed part unloading

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

Take a look at the other products and choose the best solution

Combi Genius

PUNCHING AND LASER CUTTING COMBINED MACHINES