Células de plegado robotizadas

CÉLULAS DE PLEGADO ROBÓTIZADAS

Eficacia en cada aplicación

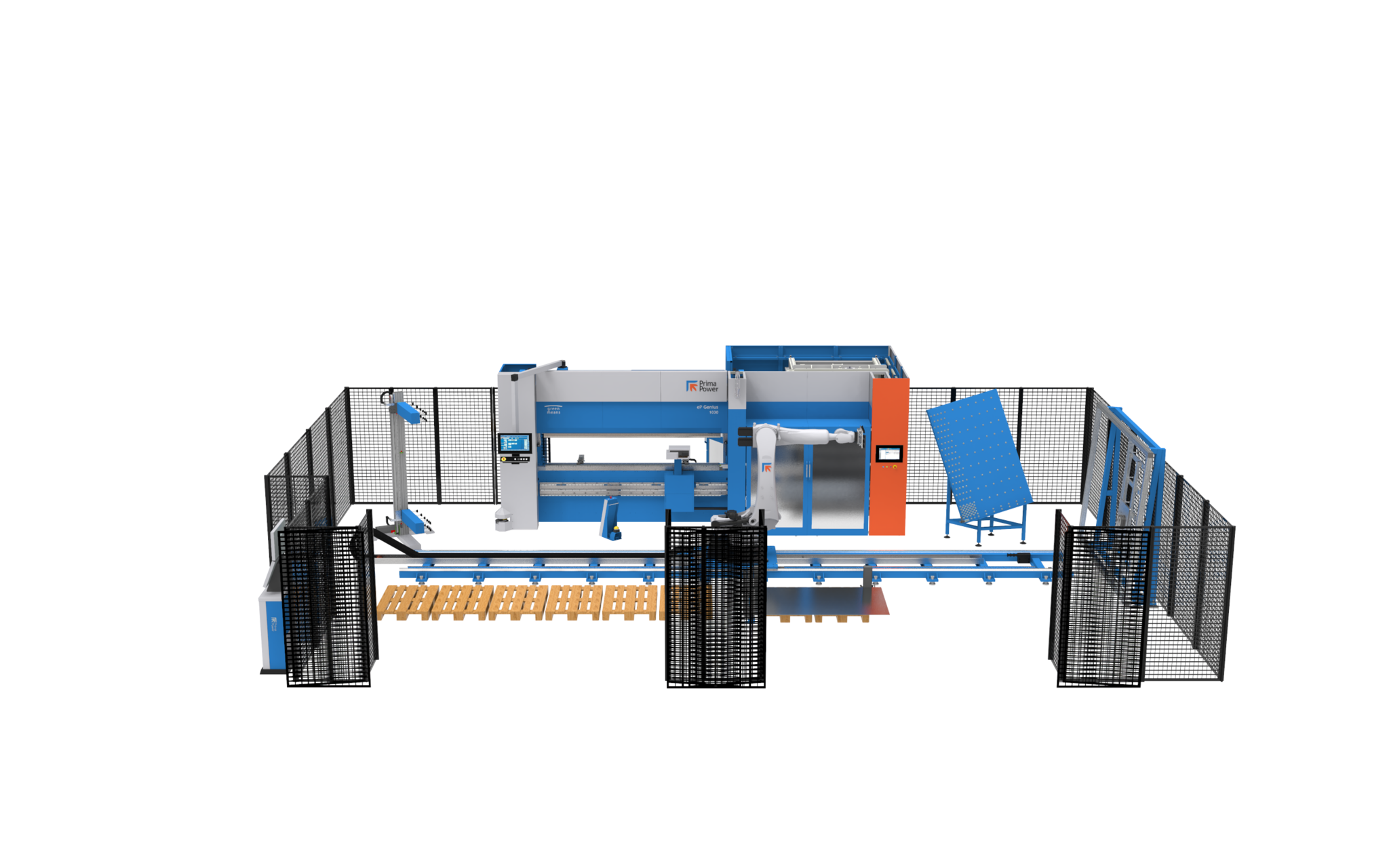

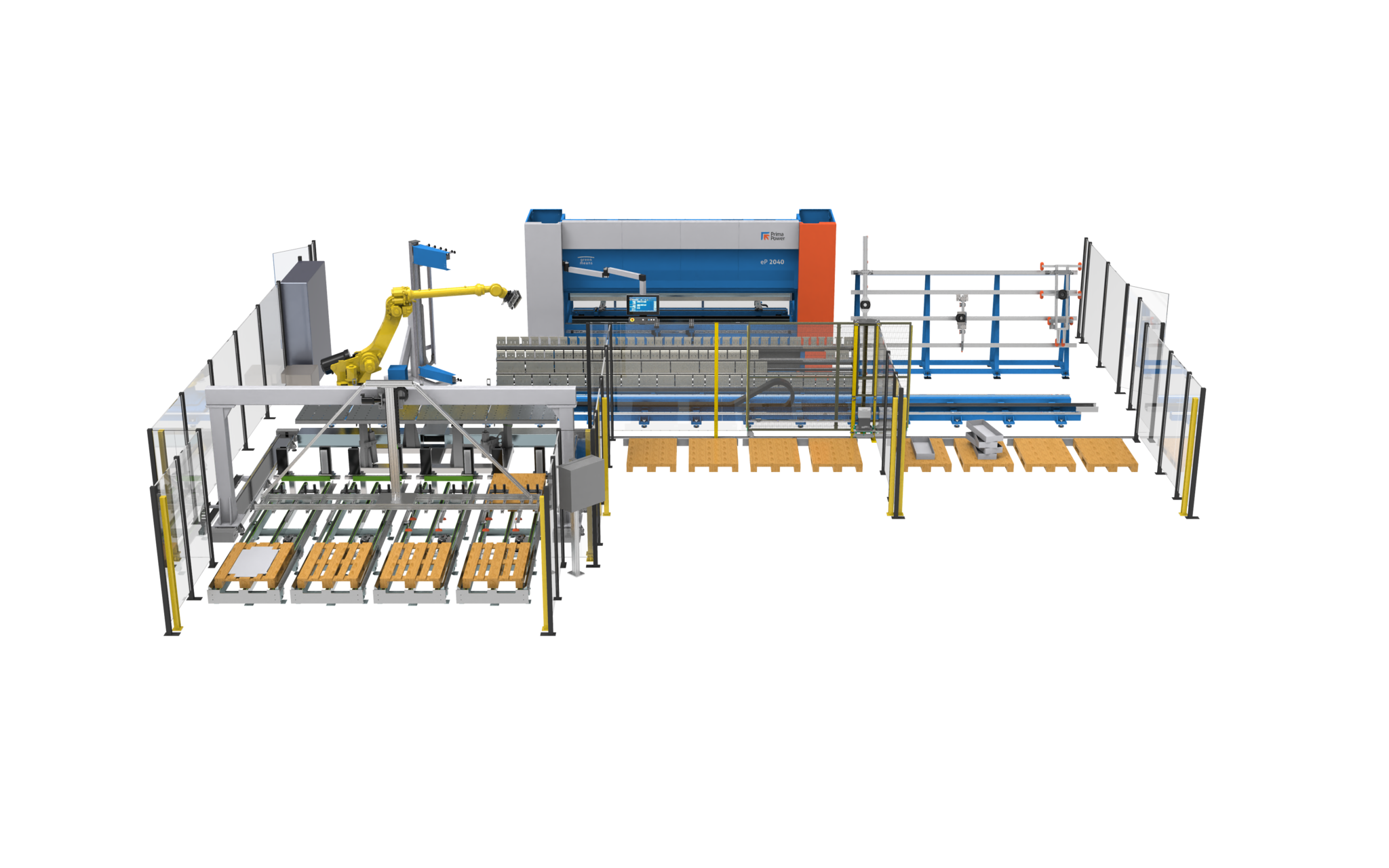

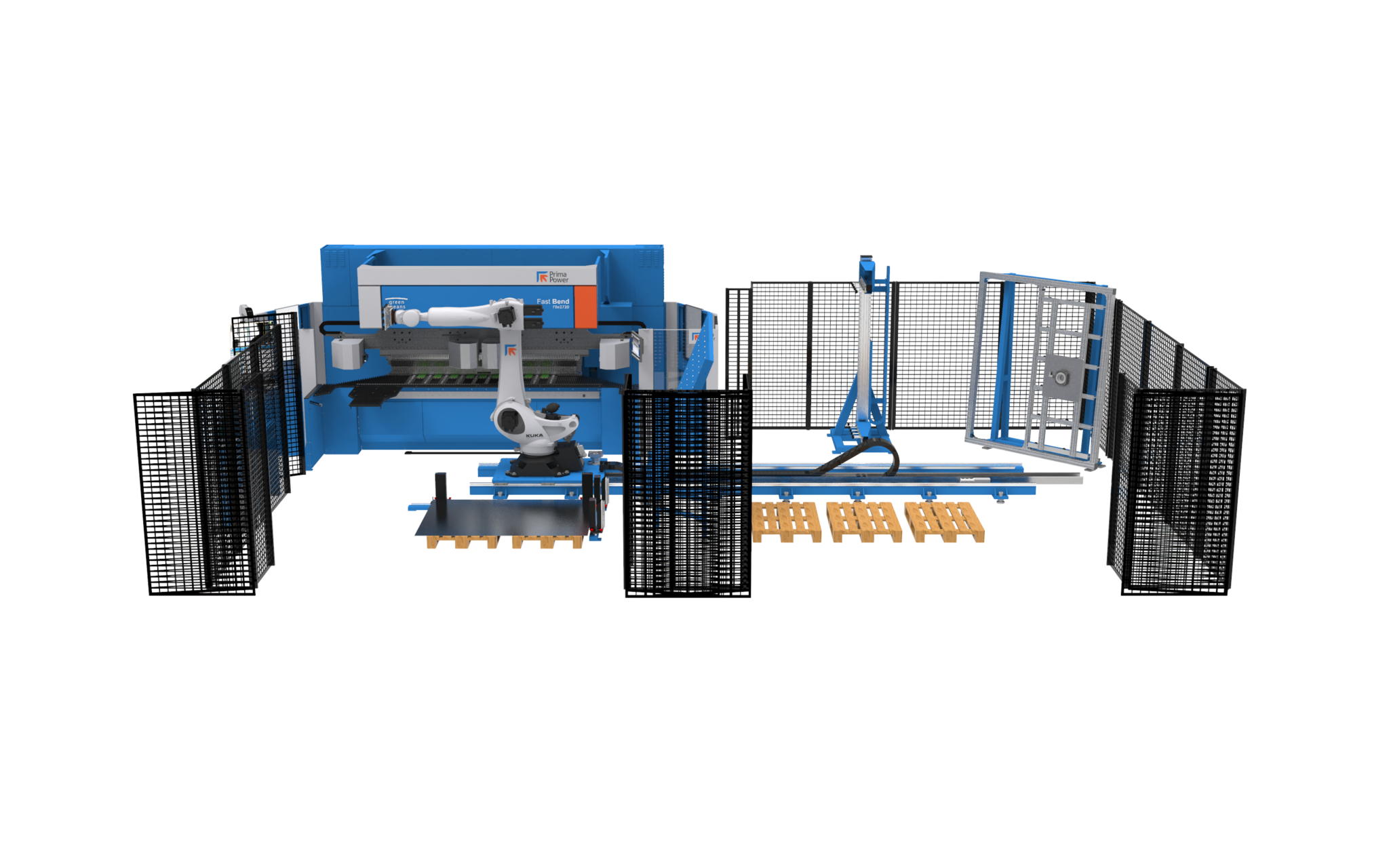

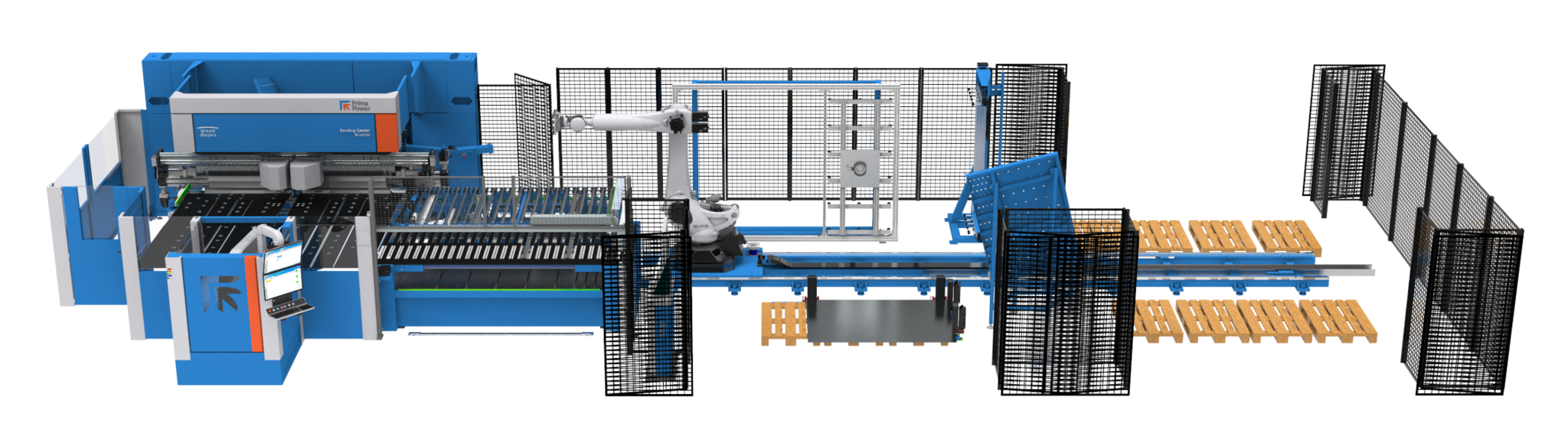

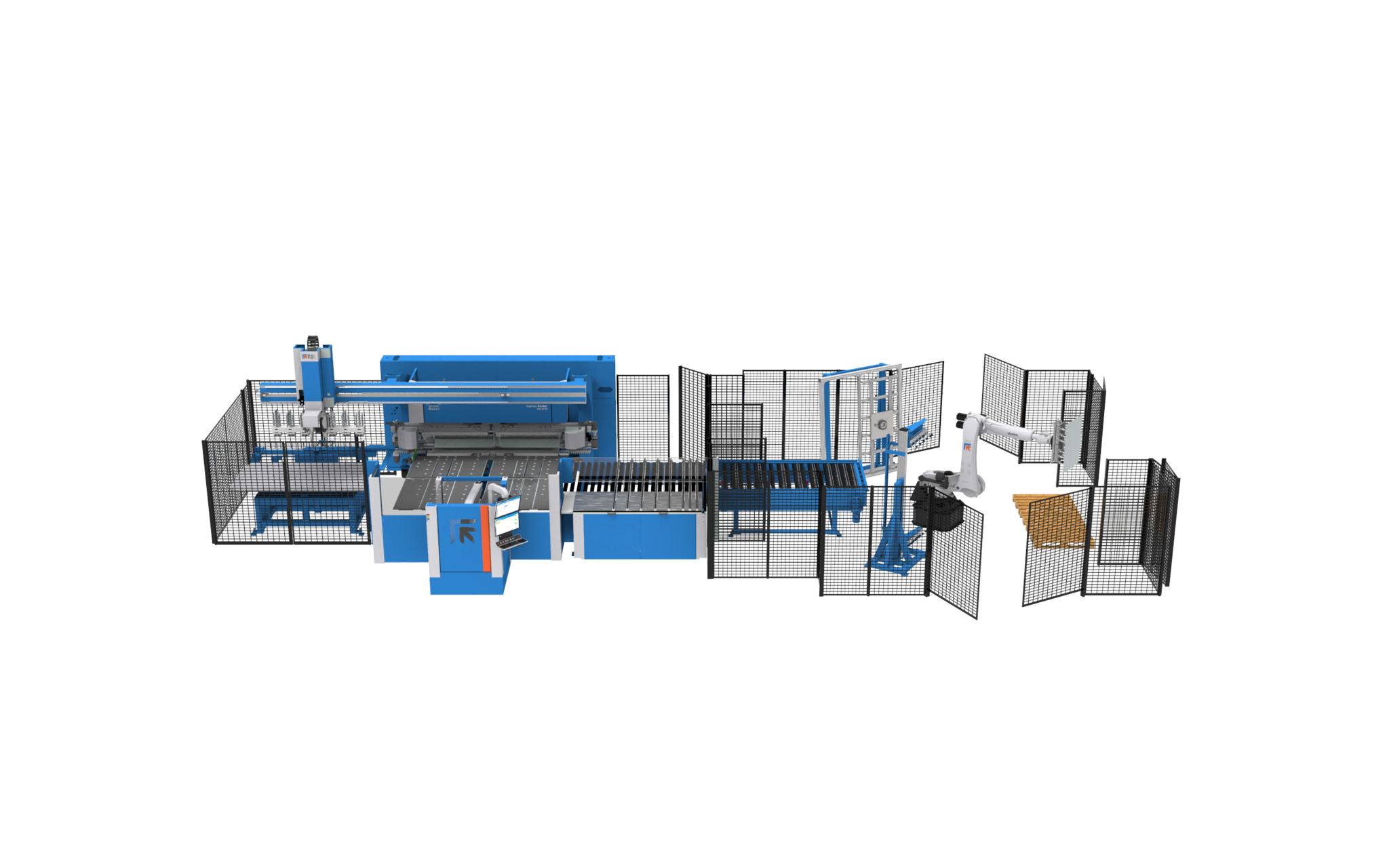

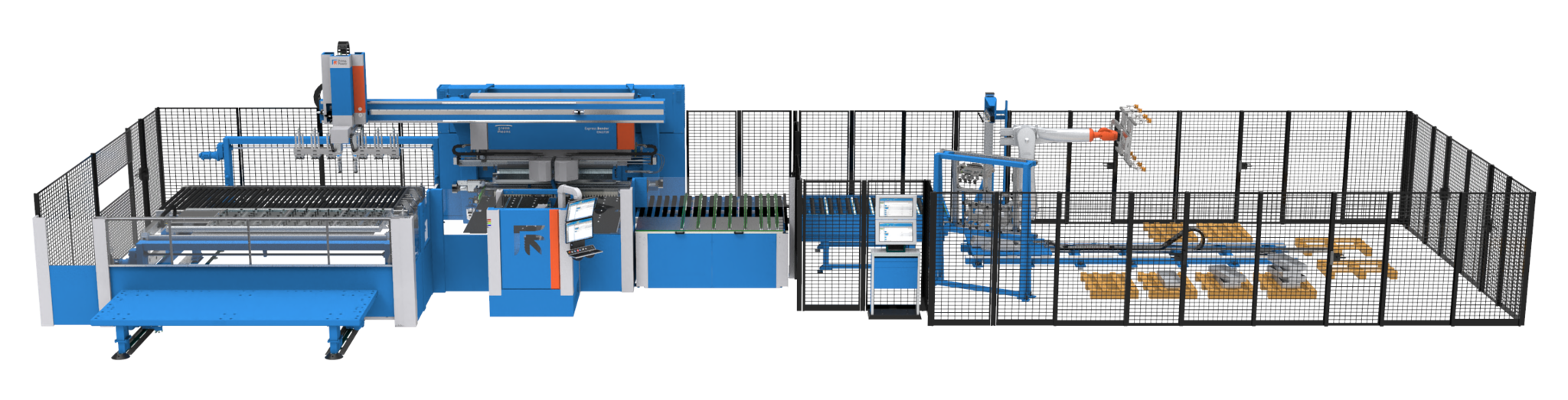

Flexible standalone bending cells for diversified applications thanks to the integration in a panel bender or press brake.

High repeatability of the parts and fast return of the investment, thanks to the robot assisted bending process applied to the servo-electric technology.

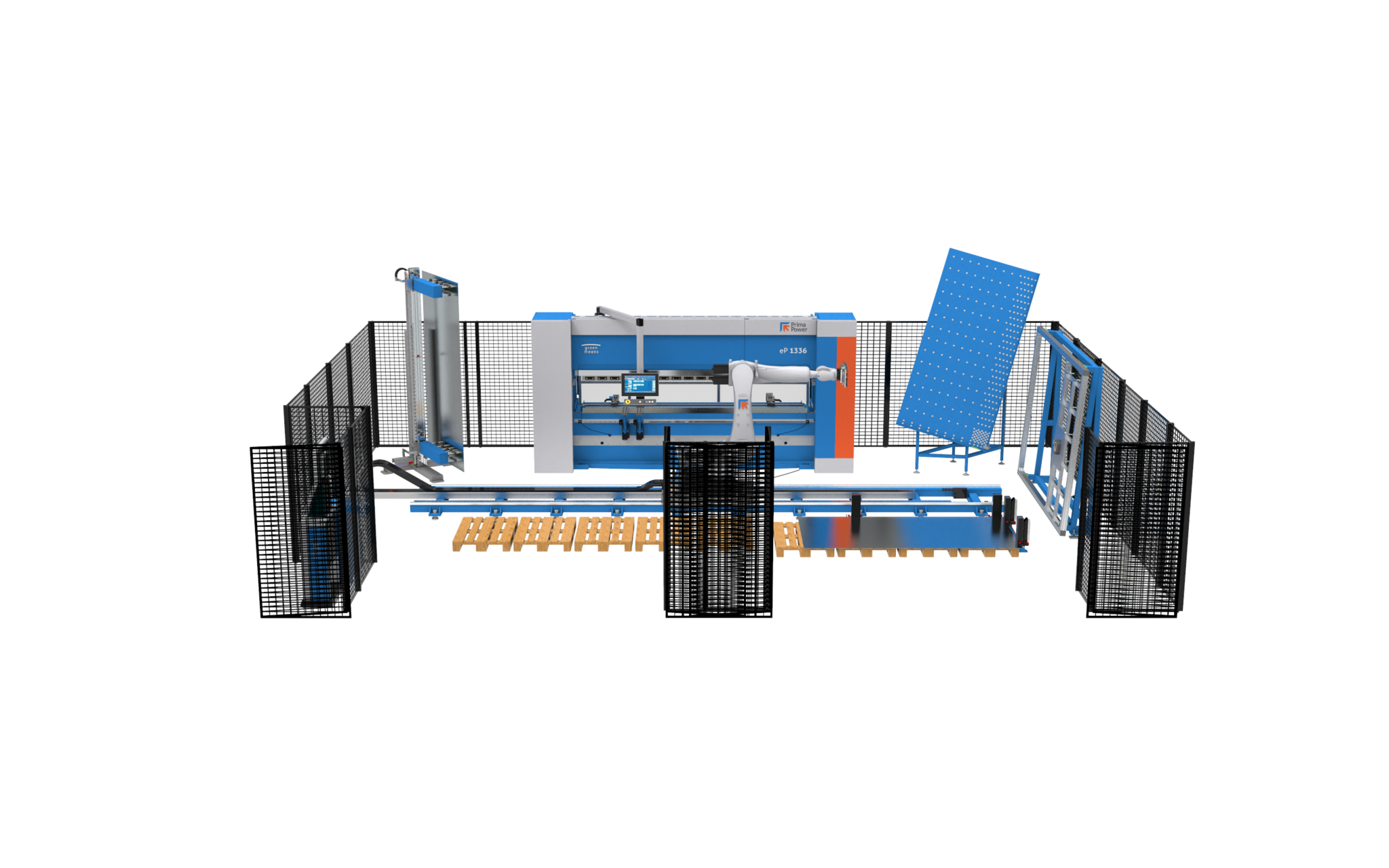

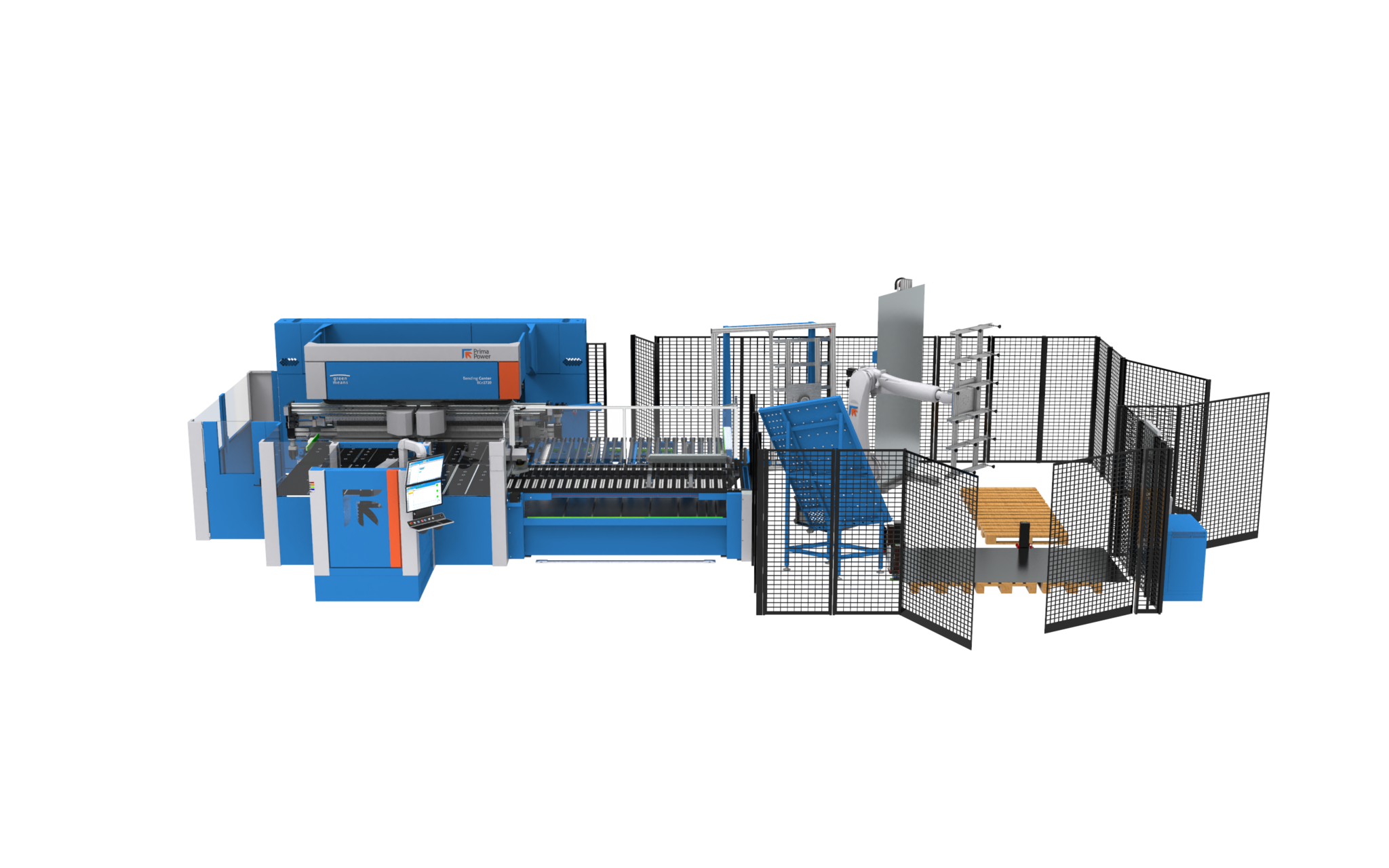

Fully unmanned production combined with the widest range of modular machines that integrate cutting, stacking and laser.

Process-oriented approach simplifies and optimizes production flow through advanced robotics integration and modular automation.

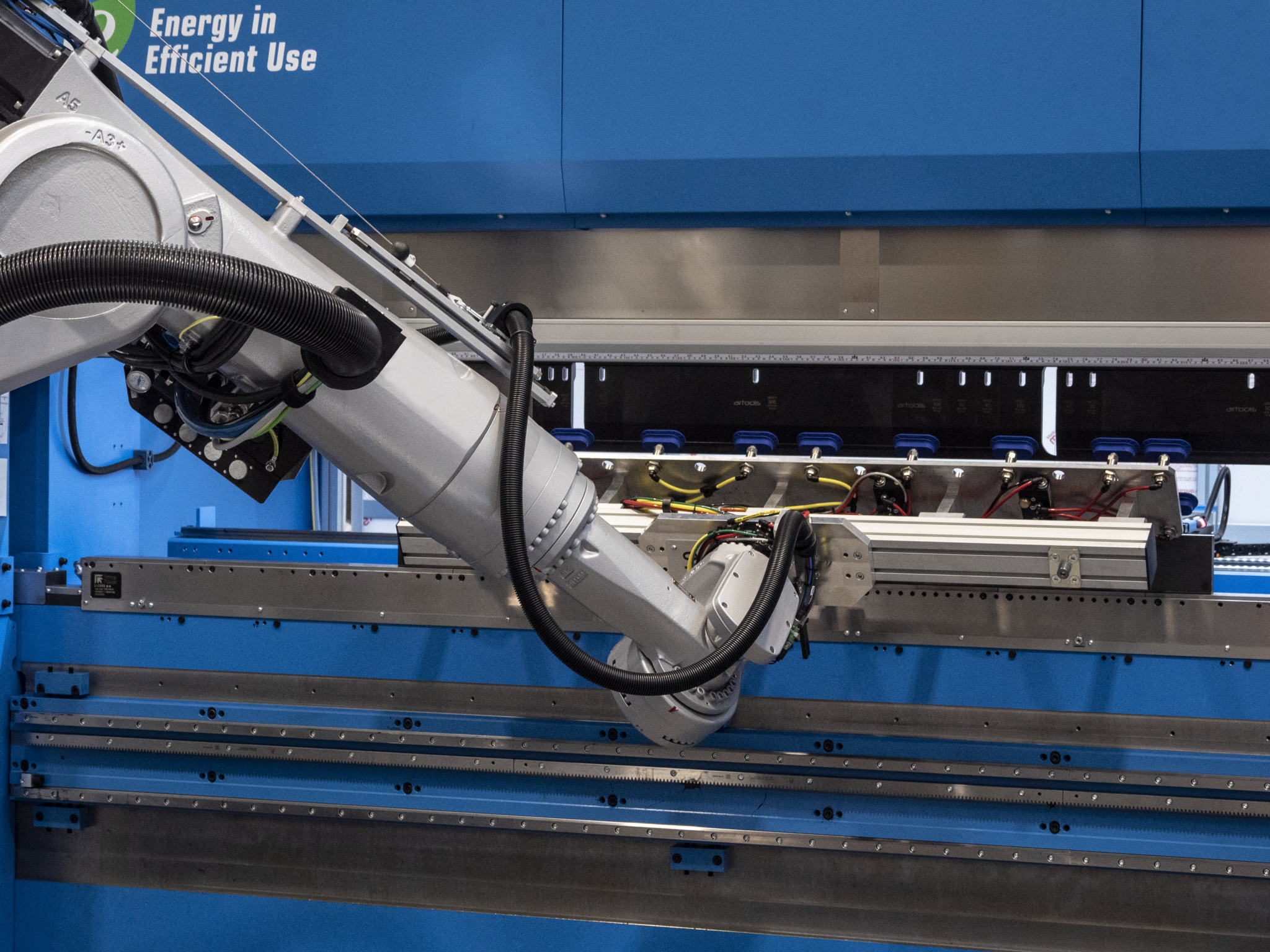

Robotics integration is the key to unlocking greater efficiency, flexibility, and productivity in sheet metal manufacturing.

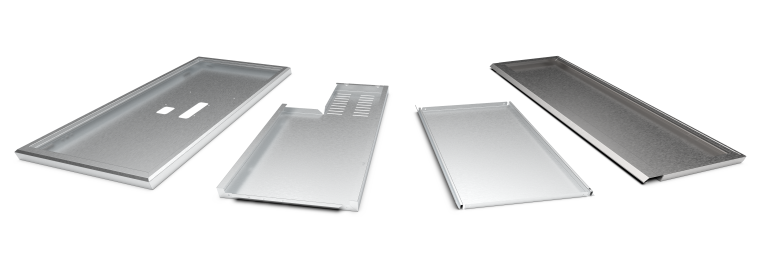

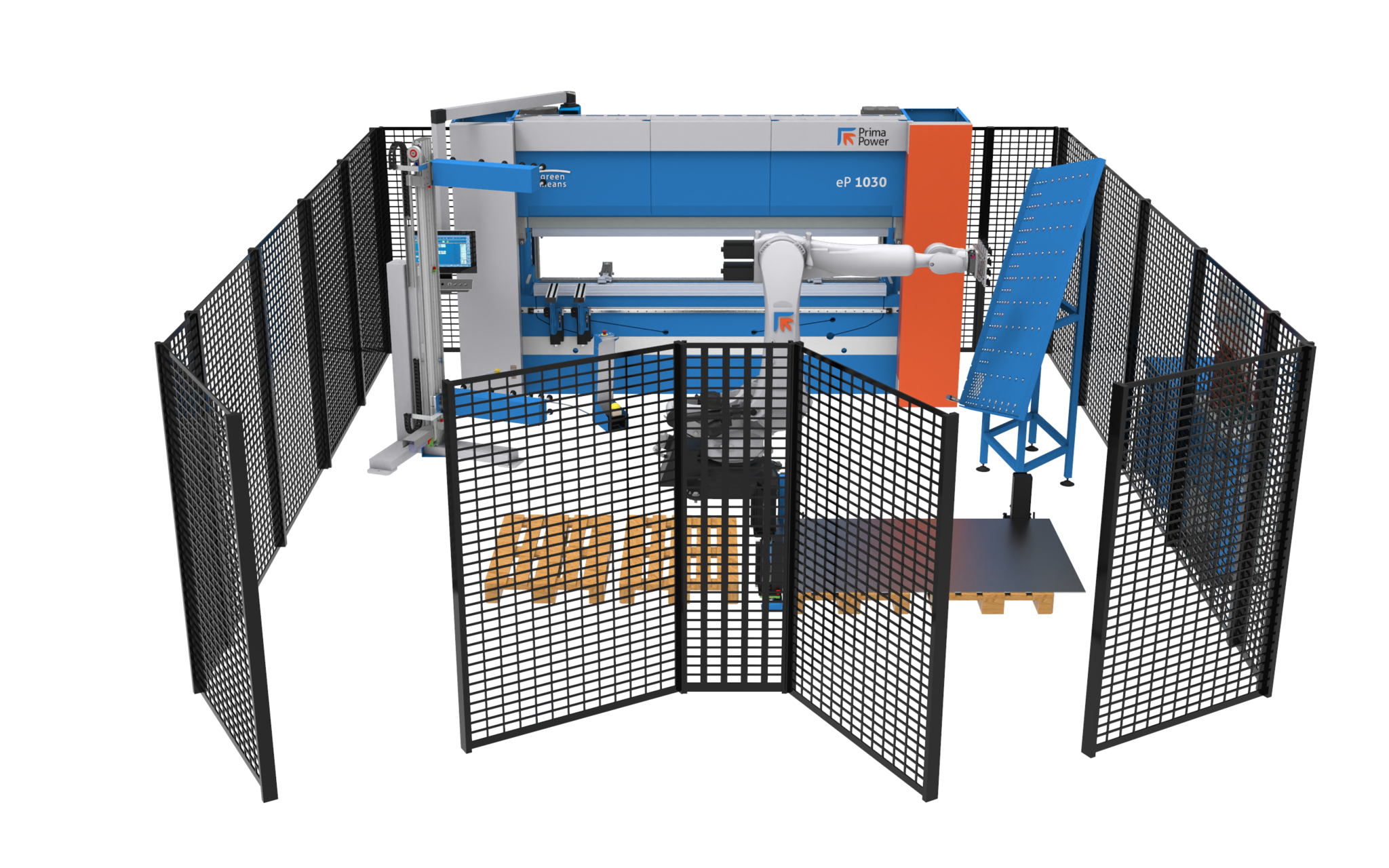

The great versatility of our Robotic Bending Cells allows them to find proper applications in any industrial segment and adapt to batches of any dimension. Our Robotic Bending Cells can be personalized according to customer needs. The several available sizes of the press brake or panel bender, the robot, the tools supplied are evaluated based on two scenarios: the autonomy desired by the customer (i.e., how much the operator needs to intervene to feed or unload the line) and the required automation level, such as the use of automatic systems for tool change.

The flexibility in personalization ensures that our robotic bending solutions achieve the best operating conditions in any application field.

Designed to meet the diverse needs of OEMs and job shops of any size, Prima Power's Robotic Bending Cells offer:

Fully automated operation ensuring high efficiency and productivity even for small production runs.

Extreme flexibility and versatility to handle a wide range of metal types and thicknesses, making our Robotic Bending Cells suitable for a variety of applications. Their modular design allows for easy customization and scalability, ensuring that they can be adapted to each customer's specific requirements.

High precision and repeatability to ensure consistent quality and reduce the risk of errors.

Optimized layouts that reduce footprint and simplify integration into the factory while enhancing efficiency.

Optimize your Prima Power machine

Tul-Robot

H.M.I.

La interfaz del operador que permite gestionar el sistema y los programas de piezas durante la fase de producción.

Tecnologías relacionadas

Industrias relacionadas

AUTOMATIZACIONES RELACIONADAS

Night Train FMS®

SISTEMAS DE MANUFACTURA FLEXIBLE

Solución de tecnología líder en sistemas de manufactura flexible automatizada

Fast Bend FBe

PANELADORAS

La respuesta a múltiples aplicaciones. La solución de plegado semiautomática para una producción sencilla, flexible y accesible.

Centro de panelado BCe

PANELADORAS

Paneladora semiautomática que combina flexibilidad y productividad

HISTORIAS DE ÉXITO

Descubra cómo una máquina Prima Power Robotic Bending System participó en el éxito de una empresa

Un vistazo a la tecnología detrás de las plantas avícolas orgánicas de llave en mano

SKA srl fabrica sistemas avícolas para la avicultura orgánica de libre pastoreo con altos niveles de personalización de productos aprovechando la tecnología innovadora de Prima Power.