50-year-old Piristeel invests in strong growth

Piristeel is Finland’s leading rainwater system and roof safety product manufacturer, especially known for its Pisko brand. The company celebrated its 50th anniversary in 2024

Piristeel’s vision is to pioneer safer buildings and to be known for its innovative, high-quality products. Responsibility, respect for nature and continuous improvement are also key aspects of the company’s operations. The company’s ideas for product development come from customer feedback, market research and in-house innovation. Making sure that the products are safe, aesthetically appealing and easy to install is essential for the company.

Piristeel manufactures its products in high quantities: for example, nearly 1,000 kilometers of snow guards, 100 kilometers of roof walkways, 50,000 ladders and 1,000 kilometers of gutter accessories each year. Piristeel’s customers are companies that deliver and install Piristeel’s products to the end customer.

“Our customer companies purchase, for example, a gutter machine and sheet metal coil from us and then make the needed gutters and install them to their own customers” says Plant Manager Harri Peltonen.

Piristeel has previously operated out of several facilities in the cities of Lapua and Kauhava. In 2019, the company’s operations were centralized to one place, Prima Power’s old Kauhava facilities. In connection with the move, the property was renovated in several ways, for example, the plant’s floors were redone and the lighting was updated to LED lights. In addition to the renovations, the plant facilities were expanded by 2,000 m² due to which the surface area now totals 19,000 m².

“Despite this, we quickly found these facilities too cramped for us as well. That is why we transferred our product testing functions to our old Kauhava facilities” Peltonen explains.

Piristeel was a family business for a long time until it became part of Ruukki Construction and its Roofing business unit in 2019. Ruukki Construction is part of the SSAB Group. After its acquisition, Piristeel began investing heavily in growth. The new owner’s investment of approximately 10 million euros enabled the company to expand its plant and invest in new machines.

Ruukki Construction manufactures steel-based construction products and offers various services. Piristeel is part of the group’s Whole Roof in One Go strategy, the idea of which is to offer complete roof packages in one delivery to the customer, including roof safety products and rainwater systems. Due to its acquisition, Piristeel’s foreign trade has improved and exporting has grown significantly, especially to the Scandinavian countries, the Baltic countries and Poland.

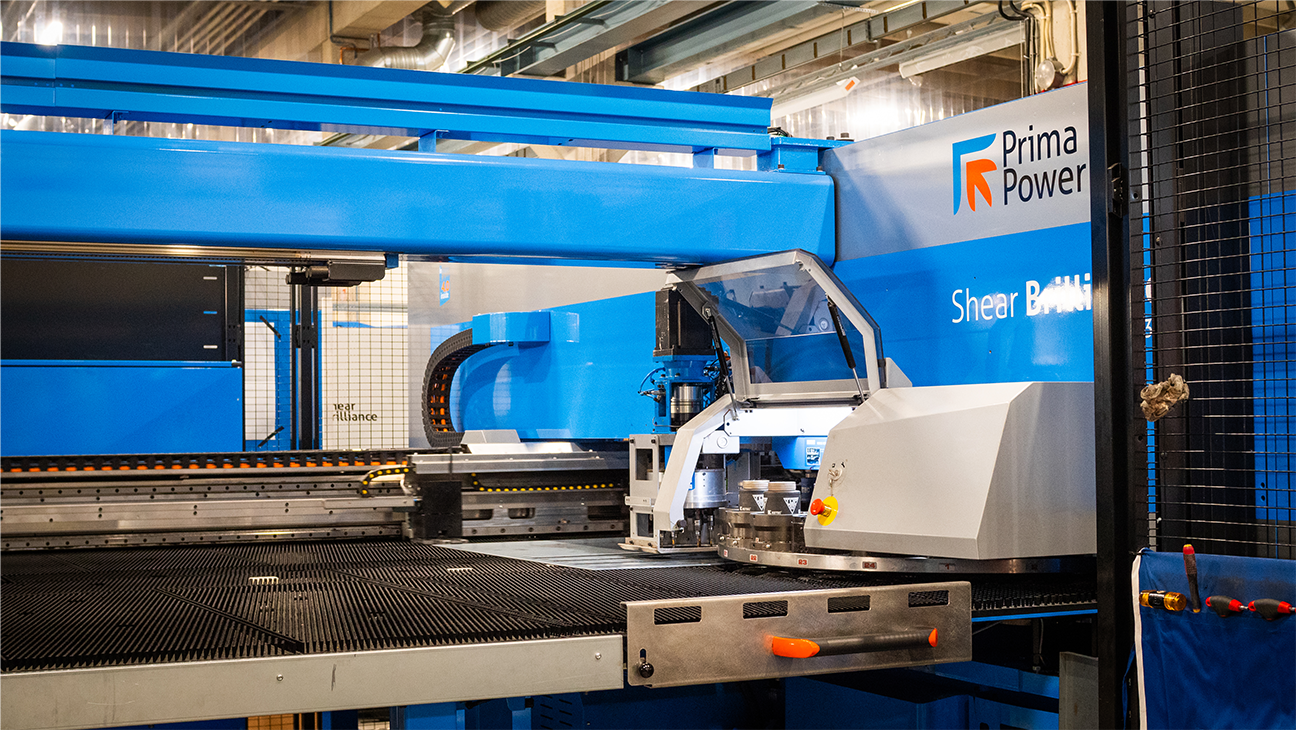

New generation Shear Brilliance

Piristeel also invested in growth by acquiring a new machine. In 2022, it purchased a combined punching and shearing machine, Shear Brilliance, from Prima Power. The new-generation machine was introduced at the EuroBLECH trade fair held in Germany in the autumn of the same year.

Shear Brilliance enables very economical and fast manufacturing, especially of rectangular parts that are punched first and then cut loose in the same automated process with the integrated right angle shear. Parts with three or two straight edges are also perfect for cutting with a right angle shear. The company’s experience with the machine has been positive.

High tooling capacity as the selling point

Team Leader Janne Halmesmäki says that Shear Brilliance’s high tooling capacity was one of the key reasons for the company to upgrade its Shear Genius to the new machine. Its turret can be equipped with up to 600 tools at the same time, which means a huge decrease in set-up times and improved flexibility in production.

“We decided to invest in the new machine according to our plan for future growth. Our machine capacity lagged behind due to the tooling that our current products require and its impact on set-up times” Halmesmäki says.

Piristeel's production is running unmanned during the evening and night. Employees only work day shifts. Occasionally, production is also running during the weekend if there is a need for it. This has been made possible with the efficient machine, high tooling capacity and automation.

“With the new machine, we can keep the production running in a second and third unmanned shift. The machine’s turret, which can also be equipped with drop-in Multi-Tools®, has contributed to this” Halmesmäki explains.

Halmesmäki sums up that versatility, easy adaptability, user-friendliness and the availability of diverse options are the best qualities of Prima Power machines.

He also highlights the versatile and adaptable turret that can be designed to fit the company’s own production requirements. Due to this, downtime caused by tooling set-up is minimized and machine uptime is improved also in unmanned production.

“The new Shear Brilliance has significantly increased the amount of unmanned operations in our production with a minimal amount of waste. We have a sheet utilization rate of up to 85–95%, so we do not generate much waste” Halmesmäki says.

Long-standing cooperation between Piristeel and Prima Power

The cooperation between Piristeel and Prima Power began over 30 years ago when Piristeel purchased its first sheet metal processing machine with a right angle shear in 1992. Back then, loading and unloading was carried out manually, but it was soon facilitated and accelerated by increasing the level of automation. Halmesmäki reflects on his long career at Piristeel:

“At the beginning, the company had a basic right angle shear with no sorting capabilities. That is, the sheets were loaded and unloaded by hand. At that time, I began my career at Piristeel in a summer job. In 1996, a loading and unloading line was added to the machine. I have been at the company for a long time, and I have enjoyed working with sheet metal machines of different generations. I have learned a lot during the years”

Unwavering trust in a right angle shear

Piristeel has a long history with right angle shears in particular, and the company has also piloted both generations of the Shear Brilliance machine. In addition to the latest Shear Brilliance, the company’s previous Shear Brilliance was also the latest model at the time. It was also the first one delivered to a customer, and the deal to purchase it was also struck at a trade fair in Germany. The year was 2014.

All in all, Piristeel has purchased five right angle shears from Prima Power during the years, of which two are still in use. Peltonen and Halmesmäki praise the benefits and potential of a right angle shear.

“The advantages and possibilities a right angle shear can offer do not really hit you until they present themselves. You can do a lot with a right angle shear! Among other things, it offers increased production capacity and speed”

Peltonen and Halmesmäki have both been pleased of the cooperation with Prima Power and say that it has always gone well and been effortless. They also appreciate domestic, Finnish products. They send special thanks to Prima Power’s maintenance team:

“We appreciate the high-quality maintenance service that Prima Power provides. Their professional maintenance team knows what they are doing! Often, things are resolved already during the initial phone call or the matter is forwarded to the right person quickly. The people carrying out our annual maintenance and inspections have always provided excellent and thorough service” Halmesmäki says.

“Support from the machine’s manufacturer is always important. The services offered by manufacturers is a deciding factor when we are making an investment decision. The world’s most efficient and fastest machine does not benefit you if you cannot use it due to a lack of support” Peltonen concludes