The challenge was to keep pace with the rapidly growing production requirements with two older CO2 lasers, one of them

was worn out and needed to be replaced. The management of R & M Manufacturing made the decision to purchase a fiber laser, and obtained quotes from multiple fiber laser manufacturers. R & M evaluated the time studies, cost of ownership studies, efficiency comparisons, ease of operator usage, and programming specifications from each laser manufacturer. The company had specific needs to consider prior to purchasing the fiber laser:

- R & M needed a small footprint machine that had a very large capacity to consume materials.

- Reliable automation that could run lights out was a must. The company ran only two shifts, and the fiber laser needed to run lights out every night and every weekend. The only downtime this machine would have was for scheduled maintenance downtime.

- Material thicknesses vary from ¼” down to 20 gauge.

“We started with six possible sources,” reflects Jeff Nelson, operations manager. “We decided on the Prima Power 6kW Laser Genius with a Compact TowerServer that allows easy loading/unloading for blanks and processed sheets for lights out operation. Our decision was based on the fact that the Laser Genius is a top-of-the-line fiber laser. It is also a very high performer, and the footprint for the automation is much

smaller than the competition, which suited our needs extremely well. After doing all the studies, and evaluating the cost of ownership, the Prima Power laser came out on top.”

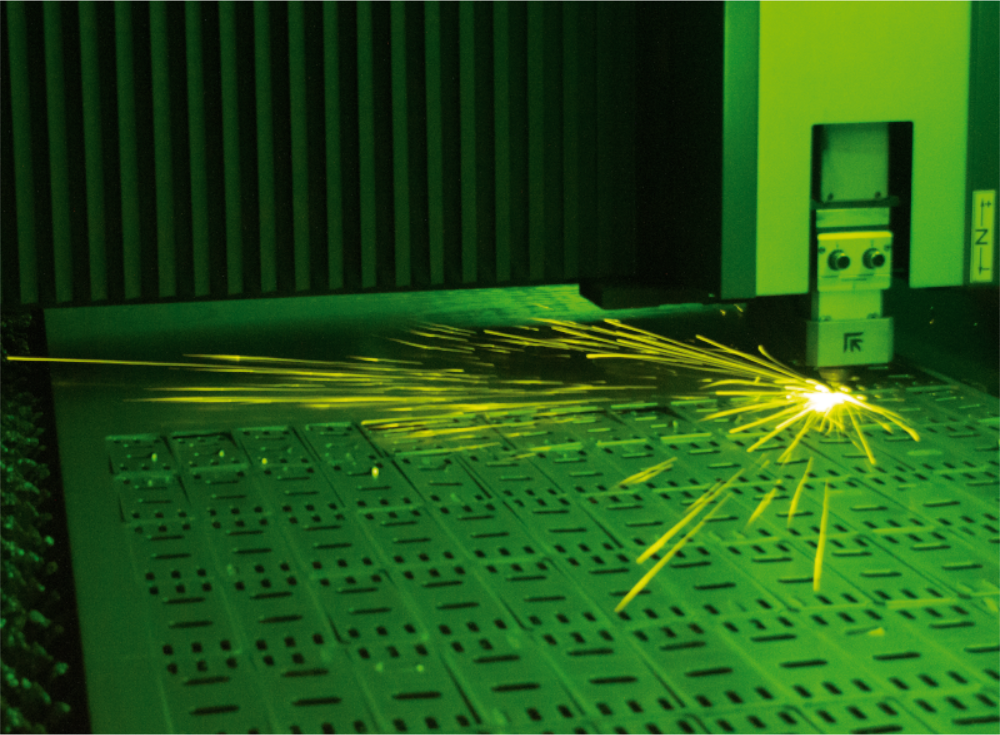

Laser Genius

Laser Genius is a high-range 2D laser cutting machine, designed for very high productivity, quality, and flexibility. Laser Genius can be used to cut a wide range of materials. Fiber lasers are more effective than other laser sources for cutting highly-reflective materials (e.g. aluminum alloys, copper, brass). Varied thicknesses can be cut with efficiency and quality. Productivity increases particularly with thin and medium-gauge sheet metal. Because of its wide range of automation modules, the Laser Genius is the right solution for both small batches and large-scale production.

High-dynamic linear motors ensure a 15% increase in productivity compared with conventional drive systems. The Laser Genius has a comprehensive range of automation modules and the effective CNC proprietary management guarantees accuracy in cutting and head positioning. “The speed of Laser Genius was absolutely another consideration,” explains Nelson. “ I needed to process more product at a faster rate. Watching the demonstrations while the machine actually ran, and the quality of the cut, were big factors in our decision to go with

the Laser Genius. Overall, the Laser Genius is the Cadillac of fiber lasers.”

Increased Efficiencies

“Laser Genius has increased our efficiencies by 30%,” continues Nelson. “When you are in my position you have to justify every piece of equipment. You have to do a Return on Investment (ROI). Some companies base ROI on new work they are trying to get, I did my ROI on work that was already in-house. The efficiencies that we gained from the Laser Genius reduced my ROI from five years to 3 1/2 years. The Laser Genius made us more competitive when quoting in the laser cutting market. These days, a lot of OEMs won’t even look at you unless they know you have a fiber laser with automation.”

The Prima Power Laser Genius is a high-tech product with low operating costs, high-energy efficiency, no laser gases, and reduced maintenance. This result is obtained from Prima Power’s proven leadership in laser technology in terms of flexibility, quality, and user-friendliness, and more than 2,000 flat laser machines installed worldwide. The Laser Genius has linear motors on X and Y axes, carbon

fiber carriage, synthetic granite frame - unique characteristics allowing it to maximize fiber laser technology at its best. Another feature that stands out is the proprietary hardware and software for laser process control and the high brilliance 6kW fiber laser.

The Prima Power fiber cutting head features single lens strategy, safe impact protection system, high dynamic focal axis with 35 mm stroke, lens drawer with quick alignment system (OPC), and protection glass drawer for easy inspection. These features make it an accurate, versatile, and efficient machine capable of 24/7 lights-out production.

“This machine gives us so much more flexibility and so much more capability, I don’t call it the Laser Genius...I call it the Hog,” says Nelson with a grin. “Because all this machine does is eat metal. The reliability of this machine has been phenomenal...far beyond what we expected.”