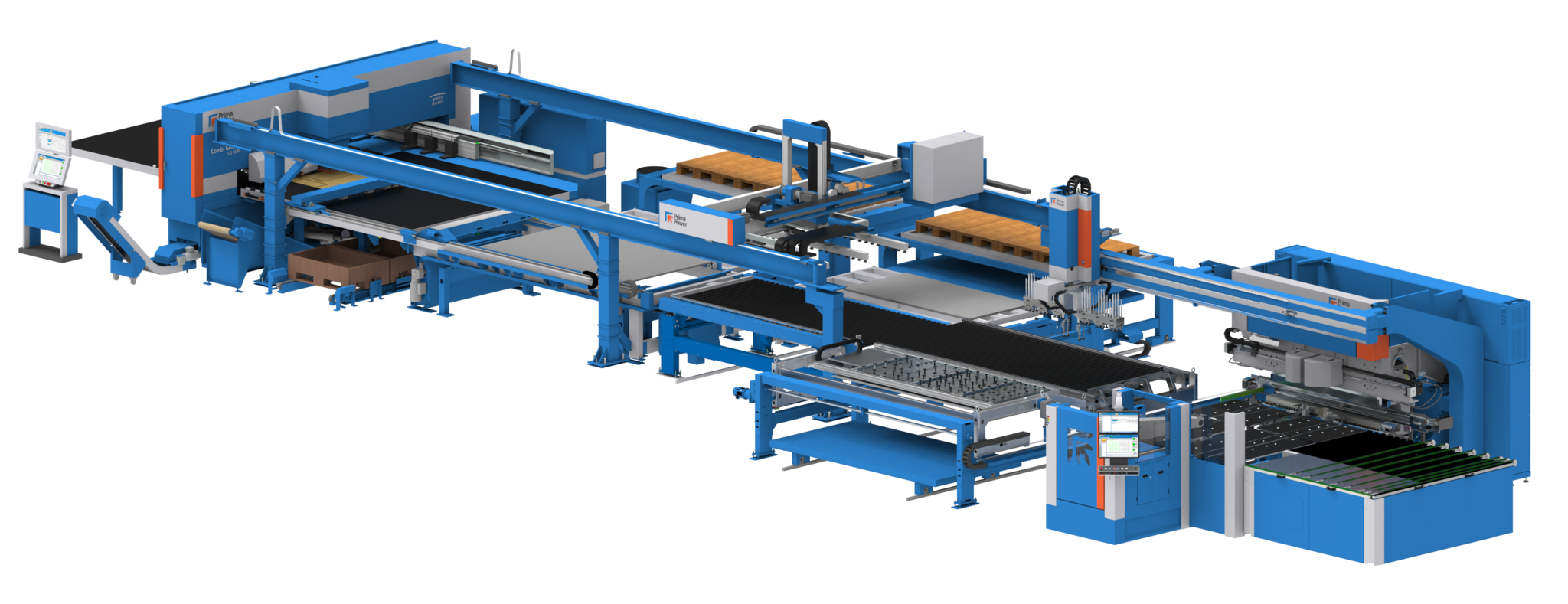

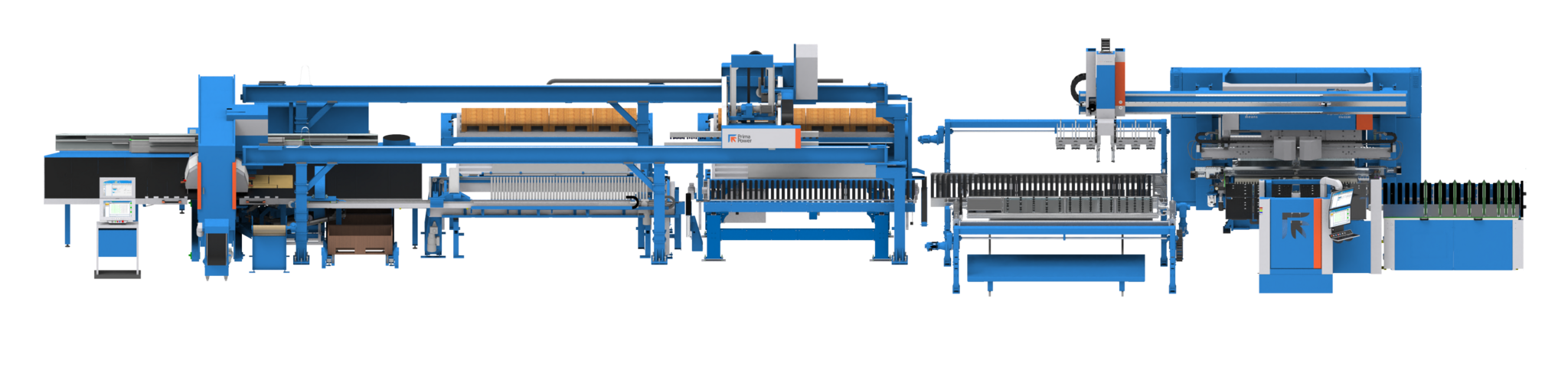

LPBB

FLEXIBLE MANUFACTURING SYSTEMS

The art of integration

ALL-IN-ONE

Punching, forming, tapping, marking, fiber laser cutting, bending

VERSATILITY

Outstanding versatility for complex manufacturing

USER FRIENDLY

Ease of operation, minimal set-up times

TRANSPARENCY

Automatic information flow from programming to production reporting

LPBB stands for Laser cutting + Punching + Buffering + Bending. The outstanding productivity offered by the LPBB flexible manufacturing system results from Prima Power modular technology and intelligent material flow management.

The compact LPBB sheet metal manufacturing system processes blank sheets into ready-bent, high-quality components automatically. The manufacturing system integrates punching, laser cutting, bending and intelligent part handling.

LPBB integrates punching, laser cutting, intelligent part handling and high-quality bending. Very fast reaction times are expected in modern production. The machine needs to be flexible and extremely fast for a quick response to production orders, often for very small quantities.

There may be a rush order, or a test series to prove delivery capacity; here the laser is often the answer. Again, in longer series punching adds manufacturing speed and cost efficiency, allowing e.g. versatile forming and provides competitiveness unmatched by individual laser or punching machines.

The productivity offered by this concept derives from the integration of:

- Versatile servo-electric punching

- Modern laser cutting

- Servo-electric bending

- Automatic, flexible material flow and

- Sophisticated software

Optimize your Prima Power machine

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

Tulus Storage

H.M.I.

Software for Combo Tower Laser and Night Train is a touch-operated user interface with visual and modern look and feel.

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

Related technologies

RELATED AUTOMATIONS

Loading and stacking robot (LST)

MATERIAL HANDLING

A high-performance automatic loading and stacking robot

Loading and stacking robot (LSR)

MATERIAL HANDLING

A material and part handling robot for punching machines and laser-punch combined machines

Unloading device Compact (UDC)

MATERIAL HANDLING

A compact solution for skeleton and micro-jointed part unloading

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

Connection to automatic bending

MATERIAL HANDLING

Direct connection to Express Bender for part bending

Cut-to-length

MATERIAL HANDLING

High productivity and flexibility with money savings

Take a look at the other products and choose the best solution

PunchBend

FLEXIBLE MANUFACTURING SYSTEMS

From cut-to-size material to ready-bent components

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

SUCCESS STORIES

Find out how a Prima Power LPBB machine took part in a company's success

Vision: that all-human drive towards evolution

Discover Brink and Prima Power partnership, a success story made of human connections.