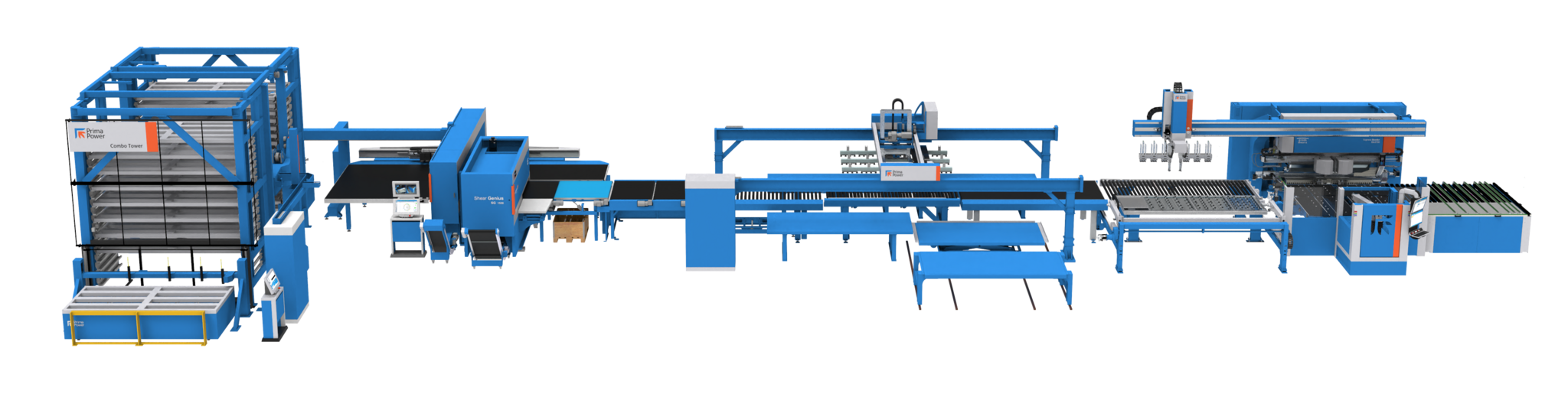

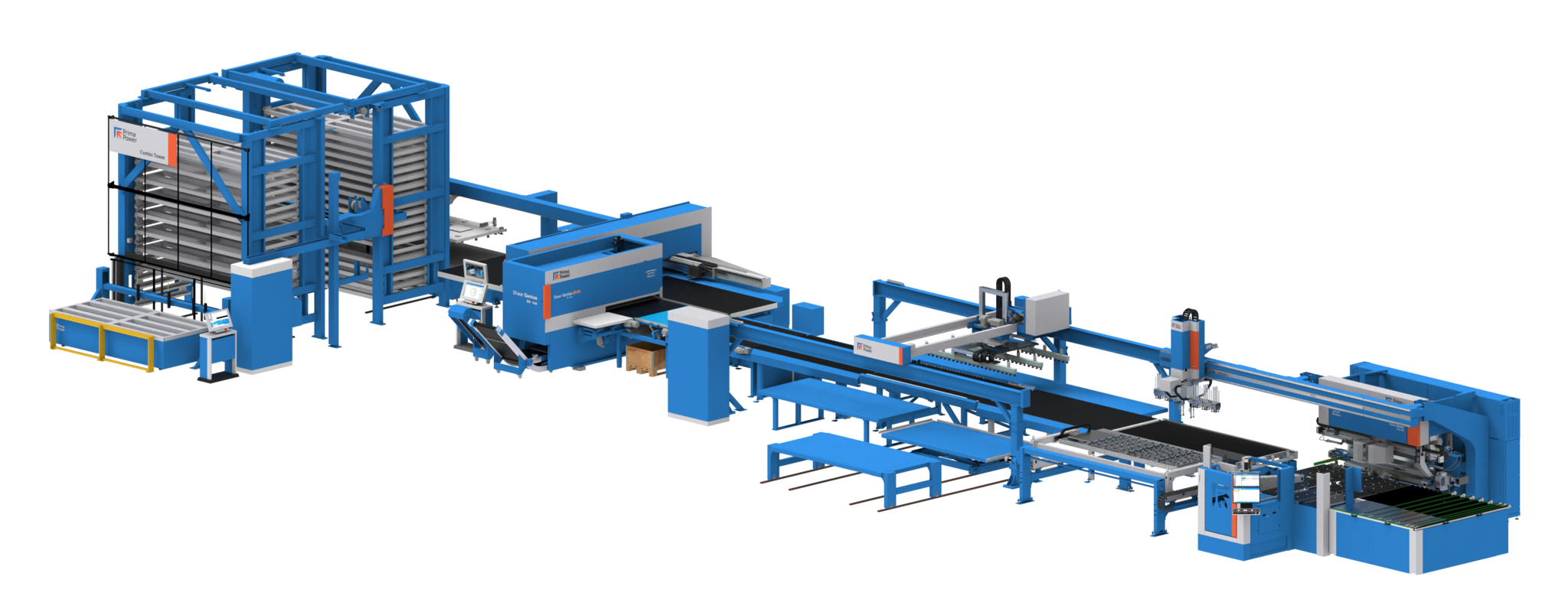

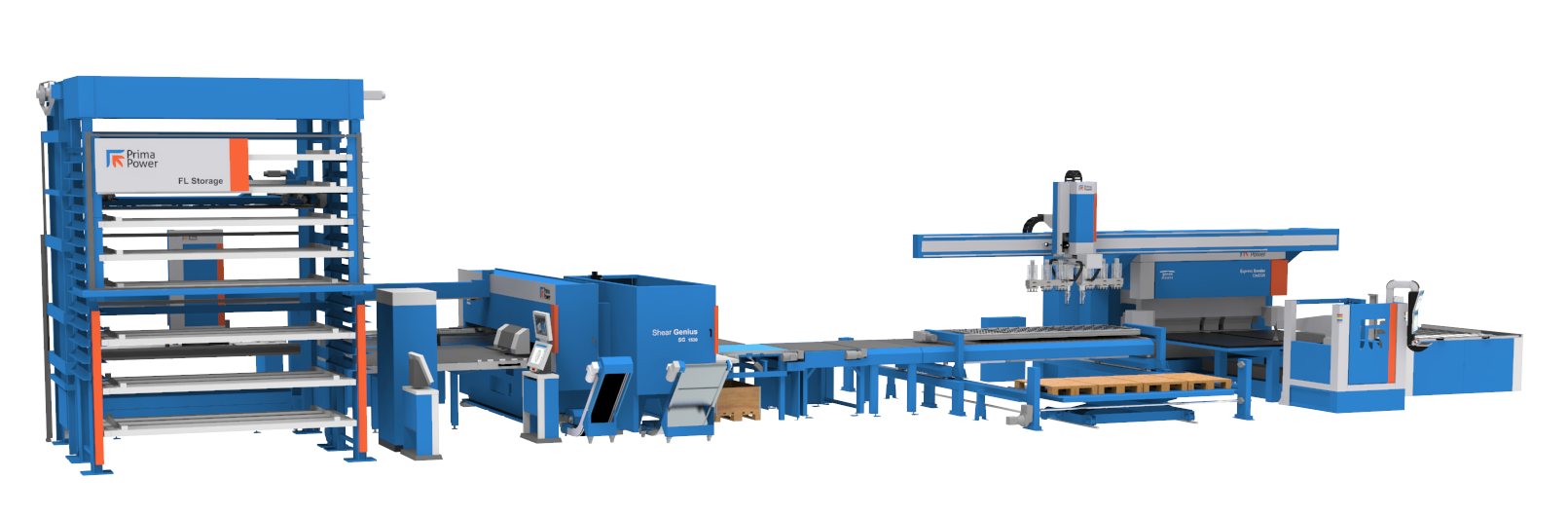

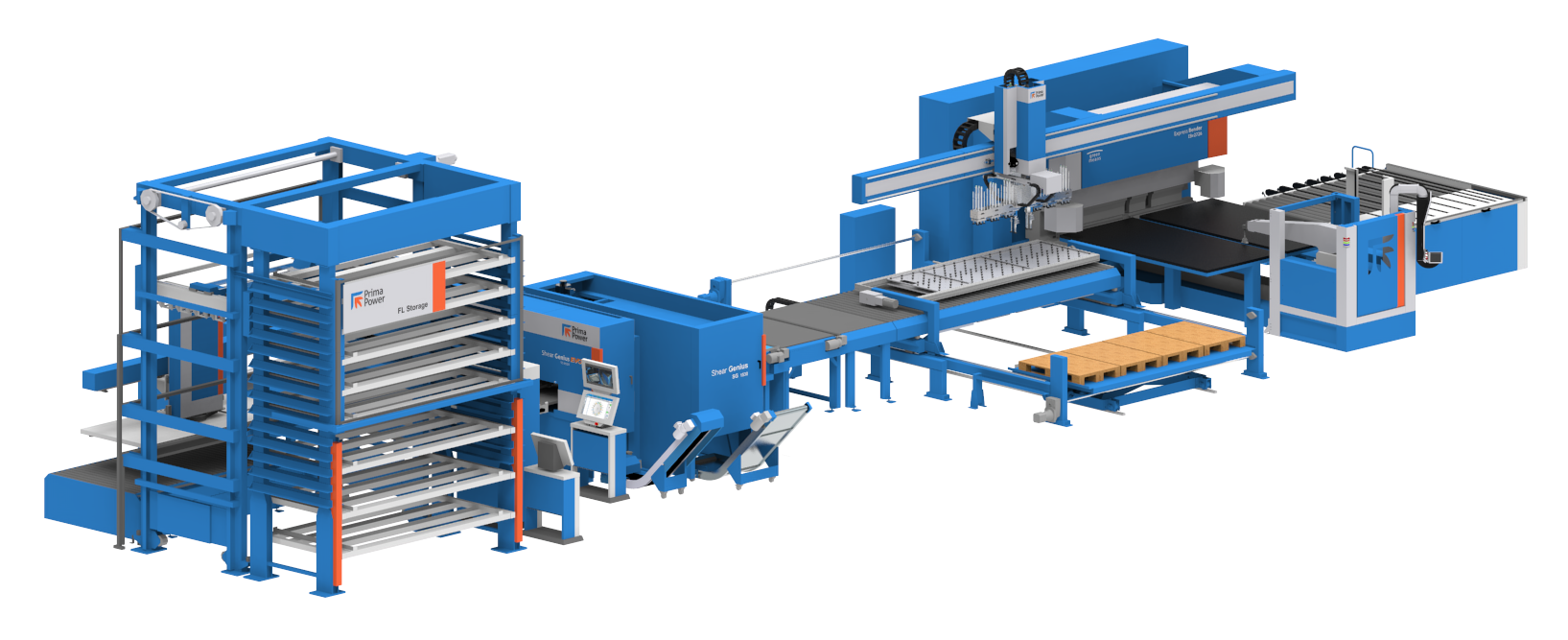

PSBB

FLEXIBLE MANUFACTURING SYSTEMS

A flexible manufacturing system

MORE CAPACITY

Less man hours and more machine hours through unmanned operation

FASTER PRODUCTION

High productivity and shorter lead time for product changes

NO SETUP TIME

Practically zero time for setup – fast, automatic material changes

TRANSPARENCY

Automatic information flow from programming to production reporting

Prima Power PSBB line processes blank sheets into ready-bent, high-quality components automatically. PSBB stands for Punching + Shearing + Buffering + Bending.

Material flow can be arranged in flexible ways: to transfer parts directly to automatic bending, to balance the different time requirements of bending and punching/shearing, to exit material from the system and to bring new material into it. The flexible and versatile buffering function ensures that optimum operation in terms of manufacturing cost and throughput time can always be chosen, whatever the manufacturing task at hand. Flexible buffering ensures optimal operation of integrated machines.

The productivity offered by this concept derives from integration of:

- Versatile servo-electric punching

- Integrated servo-electric shearing

- Servo-electric bending

- Automatic, flexible material flow and

- Sophisticated software

- Automatic information flow from programming to production reporting.

- An integrated production system, reducing the whole fabrication process into a single one.

- Automatic manufacturing stages.

- Automatic material handling including intelligent buffering.

- Minimum manufacturing time, maximum production time.

- Optimal value stream from raw material to ready-made components.

FLEXIBLE WAYS TO PRODUCE

- Direct material flow from a punching-shearing cell to the bending cell.

- Simultaneous stacking on tables/wagons and retrieval of components from tables/wagons to the bending cell.

- Use of the whole stacking area in unattended operation.

Optimize your Prima Power machine

Master BendCam

MACHINE PROGRAMMING

Efficient managing of Prima Power bending machines through interactive graphical techniques

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

Tulus Storage

H.M.I.

Software for Combo Tower Laser and Night Train is a touch-operated user interface with visual and modern look and feel.

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

Related technologies

RELATED AUTOMATIONS

Sheared part sorting conveyor (C1500)

MATERIAL HANDLING

Automatic sorting of small sheared parts

Sheared part buffering (SPB)

MATERIAL HANDLING

Sheared part buffering (SPB)

Picking and stacking robot (PSR)

MATERIAL HANDLING

The clever and flexible picking and stacking robot

Sheared part stacking system (STS)

MATERIAL HANDLING

A high capacity stacking solution for sheared parts

Easy sorting table

MATERIAL HANDLING

An entry-level sorting solution for punch-shear combined machines

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

Connection to automatic bending

MATERIAL HANDLING

Direct connection to Express Bender for part bending

Cut-to-length

MATERIAL HANDLING

High productivity and flexibility with money savings

Take a look at the other products and choose the best solution

PunchBend

FLEXIBLE MANUFACTURING SYSTEMS

From cut-to-size material to ready-bent components

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

SUCCESS STORIES

Find out how a Prima Power PSBB machine took part in a company's success

Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.