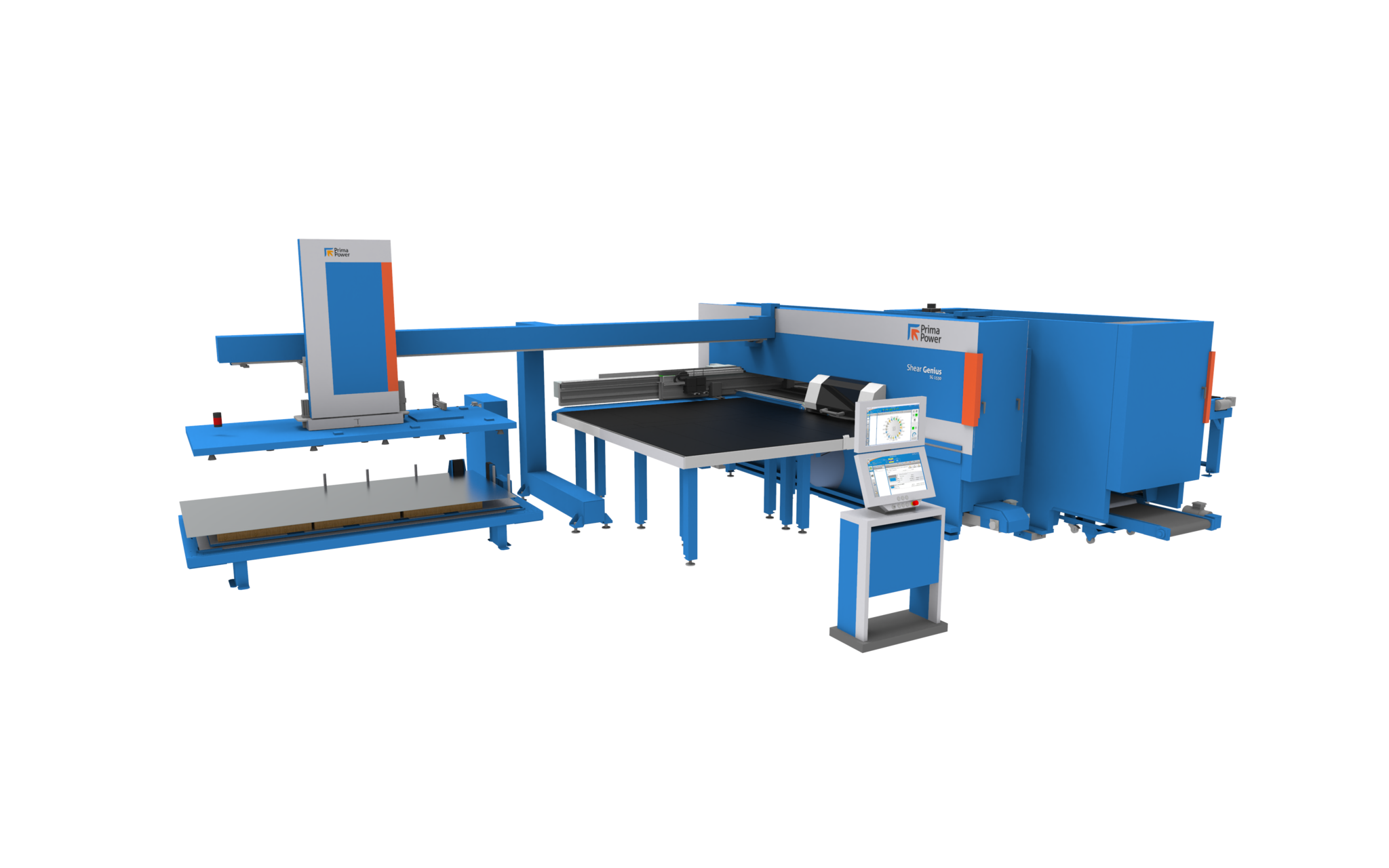

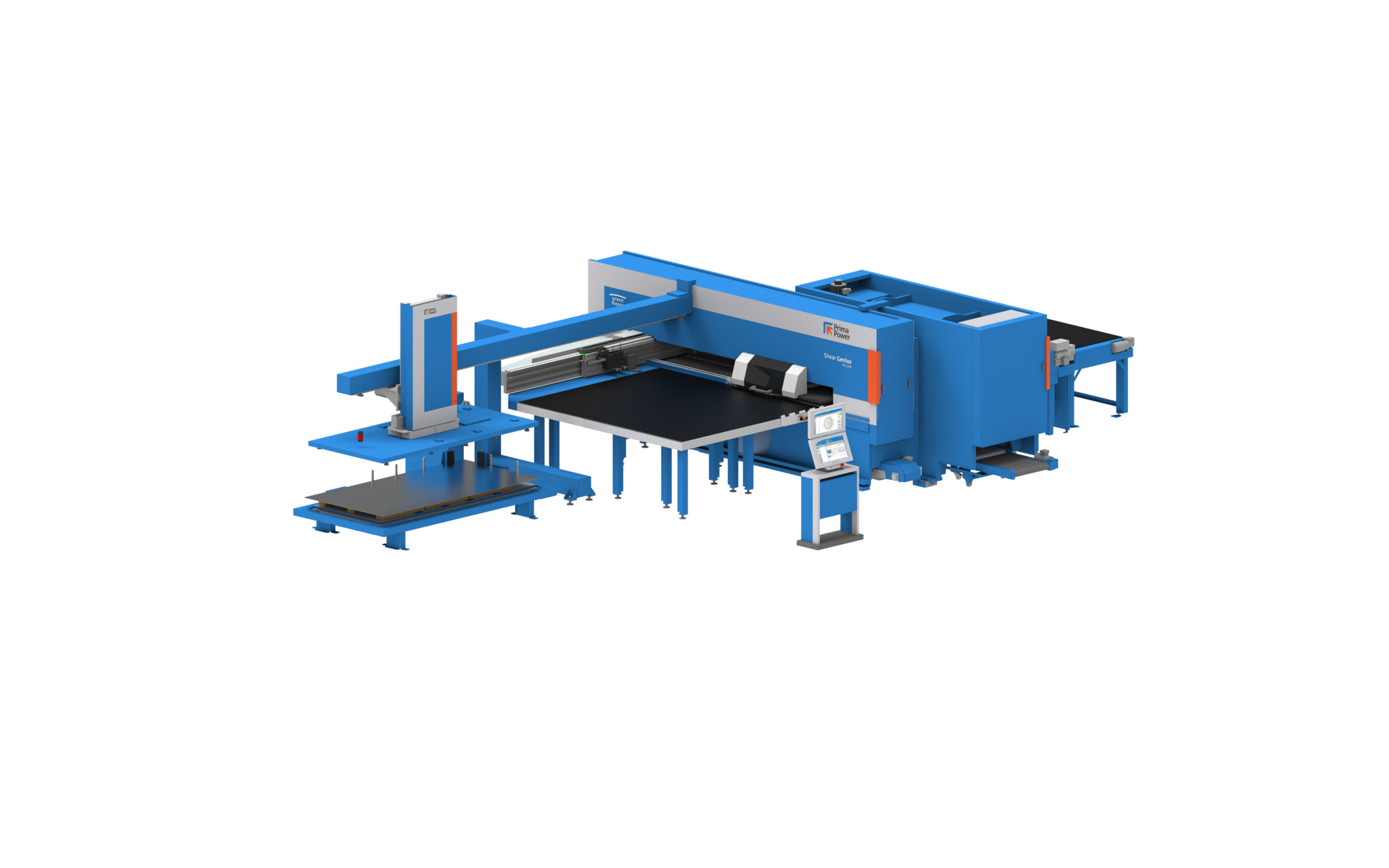

Shear Genius EVO

PUNCHING AND SHEARING COMBINED MACHINES

Highest productivity with integrated punching and shearing

ECONOMICAL

Lowest cost per part

EFFICIENT

Highest output

ECOLOGICAL

Sustainable fabrication

MODULAR TECHNOLOGY

Both machine and automation for it are modular to meet customer’s needs

The Shear Genius® EVO philosophy is to provide one machine capable of transforming square parts and panels to final products by combining additional work stages (loading, punching, forming, threading, marking, shearing and part sorting) and in this way simplifying the complete process. Shear Genius® EVO concept saves material, decreases necessary floor space and investment in separate machine tools, tooling and energy.

The core element of the machine is in its servo-electric technology, allowing sustainable manufacturing with reduced energy consumption, raw material savings and no oil waste. Shear Genius® EVO consists of a servo-electric turret punch press with integrated right angle shear and automatic loading equipment.

Prima Power's ECOPUNCH® concept is an astonishing money saver in terms of energy consumption. Compared to the traditional method Prima Power can produce more parts at the same energy.

The Prima Power right angle shear is extremely fast in operation. Programmable blade height and automatic stroke depth adjustment optimize shearing. The blade speed is automatically selected for the maximum speed. Together with automatic shearing modes, this optimizes operation speed.

Shear Genius EVO can be easily connected to automation systems in order to automatize the material and part flow and further increase the output.

HIGHLIGHTS

- Raw material loading solution with sheet edge measurement

- Smart nesting

- Trim strip destroyer to speed up the continuous production

- Fast sheet loading time and efficient production process time

The most reliable method for manufacturing square parts and panels.

ACCESSIBLE

Easy to use and monitor

INTELLIGENT RAM

More tools in turret and shorter tool change times

SCRATCH FREE

Vertically moving brushes prevent the scratching of sensitive materials

LARGE TOOLING CAPACITY

The large number of tools with Prima Power punching machines results from a set of technical features which is not available from any other manufacturer:

• Two turret construction alternatives: 16 and 20 stations

• Multi-Tools®

• A vast variety of special tools

• Rotating Auto-Index system

• Intelligent ram

BENEFITS

Servo-electric Shear Genius® EVO SG1530: the benefits

+ Fast material loading solution with sheet edge measurement

+ Efficient and economical nesting

+ Fast sheet loading time and increased production process time

+ Sheet Size / Working Area Y1565mm, X3074mm

+ Fast setup with high tool capacity

+ Low energy consumption at three power modes: run / stand by / idle

+ Low maintenance cost

+ High versatility

+ High performance values

+ Wide range of options, can also be installed later as machine upgrades

+ Automated flexible fabrication

+ Steady support for processed material during planking process with high quality brush tables

+ No skeletons, less punching scrap = savings in raw material

+ No nibble marks

+ High productivity

+ Low manufacturing costs

+ Fast return on investment

= Very high productivity in most varied applications

Two models: SG1530 and SG1540

- Max sheet size

SG1530: 3,074 mm x 1,565 mm

SG1540: 4,300 mm x 1,565 mm - Max. sheet thickness

punching: 8 mm

shearing: Aluminium 5 mm, Mild steel 4 mm, Stainless steel 3 mm - Customized turret

Max. tools in turret: 400

Max. index tools in turret: 384

Two performance levels: Pure and Dynamic

The Genius series has models on two complementary performance levels. Pure meets all the targets set for an attractively priced, yet efficient production machine; Dynamic offers the best productivity and performance in the market. Both models come with the latest features and can be equipped with the whole range of options.

- Ram force

SG EVO Pure: 250 kN (25 US Tons)

SG EVO Dynamic: 300 kN (33 US Tons) - Max. hit speed

SG EVO Pure: 700 1/min

SG EVO Dynamic: 1000 1/min - Positioning speed

SG EVO Pure: 127 m/min

SG EVO Dynamic: 150 m/min - Index tool rotation speed

SG EVO Pure: 180 rpm

SG EVO Dynamic: 250 rpm

Optimize your Prima Power machine

Tulus Cell

H.M.I.

Integrated and scalable software family for centralized management of fabrication.

Tulus Office

PRODUCTION PLANNING

Work planning and controlling all machines in the factory.

NC Express

MACHINE PROGRAMMING

Scalable CAD/CAM application that can be used for single part processing or as fully automatic batch processing software.

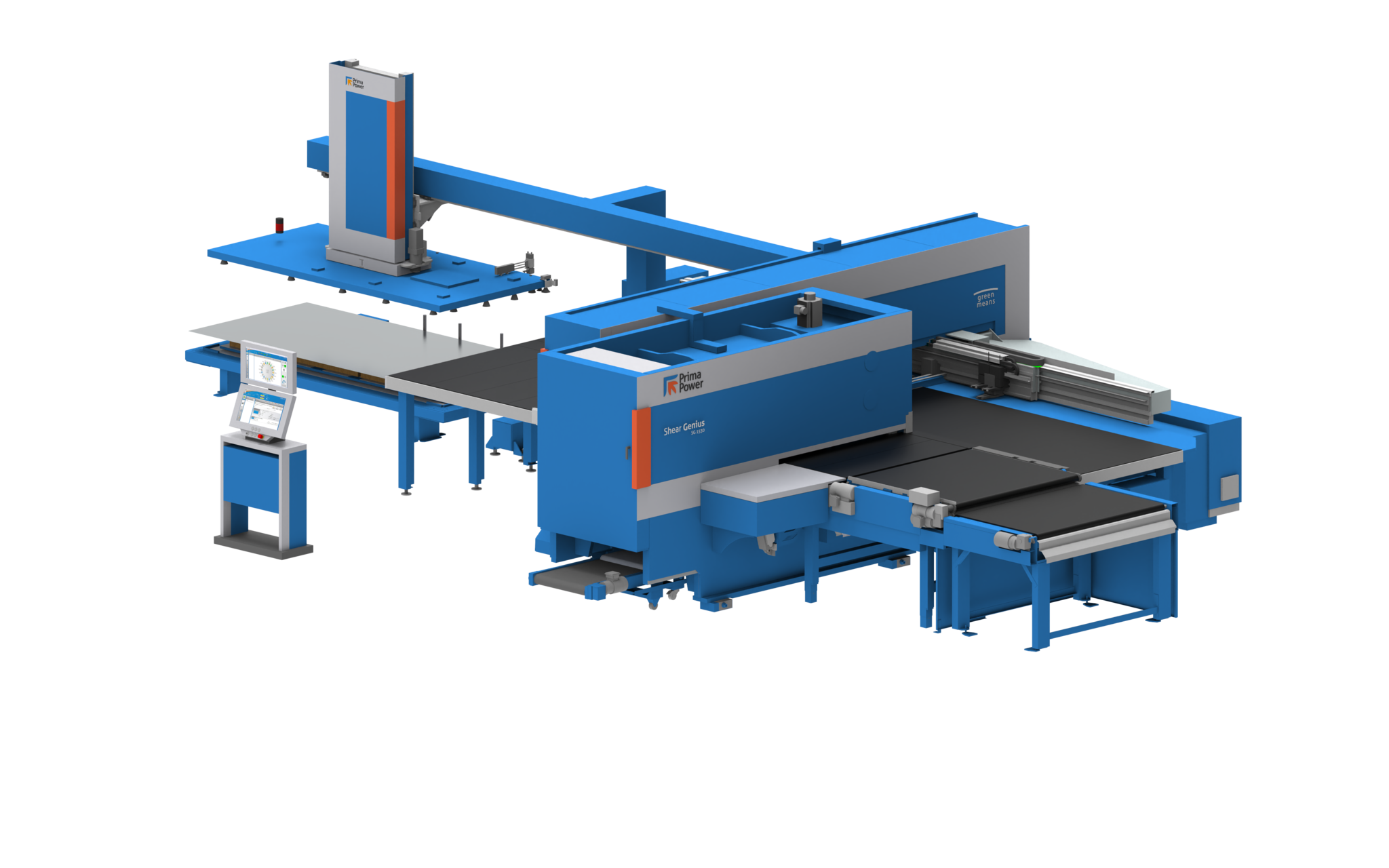

RELATED AUTOMATIONS

Sheared part sorting conveyor (C1500)

MATERIAL HANDLING

Automatic sorting of small sheared parts

Sheared part buffering (SPB)

MATERIAL HANDLING

Sheared part buffering (SPB)

Picking and stacking robot (PSR)

MATERIAL HANDLING

The clever and flexible picking and stacking robot

Sheared part stacking system (STS)

MATERIAL HANDLING

A high capacity stacking solution for sheared parts

Easy sorting table

MATERIAL HANDLING

An entry-level sorting solution for punch-shear combined machines

Connection to automatic bending

MATERIAL HANDLING

Direct connection to Express Bender for part bending

Night Train FMS®

FLEXIBLE MANUFACTURING SYSTEMS

Leading technology storage solution in automated flexible manufacturing systems

Fast Loading storage

STORAGE SOLUTIONS

A fast and economical solution for material flow

Take a look at the other products and choose the best solution

Shear Brilliance

PUNCHING AND SHEARING COMBINED MACHINES

Outstanding productivity

SUCCESS STORIES

Find out how a Prima Power Shear Genius machine took part in a company's success

A perfect combination for the medical sector

Aluminum and stainless steel are the materials used by Alvi to produce trolleys for the hospital, laundry, retirement home, hotel, industrial and textile sectors.

Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

New investments create productivity at Halton’s Kausala factory

Halton Group is the world's leading provider of indoor air solutions. Indoor air solutions are divided into four segments: Marine, Health, Foodservice, and Buildings

Punch-Shear Combo – A Labor Saver

Shear and punch fabrication of sheetmetal parts at custom door manufacturer LaForce, Inc. more than triples thanks to implementation of a new servo-electric punch-shear combination machine.

A look at the technology behind turnkey organic poultry plants

SKA srl manufactures poultry systems for organic free-range farming with high levels of product customisation by taking advantage of innovative Prima Power technology.