Technoblech - Evolution empowered by combined cutting solutions

The transformative power of innovation and leadership in the sheet metal industry

REFLECTING ON TECHNOBLECH’S JOURNEY, PIONEERING MANAGING DIRECTOR RON FRIEDL SHARES THE COMPANY’S EVOLUTION FROM CRAFTSMANSHIP TO CUTTING-EDGE AUTOMATION.

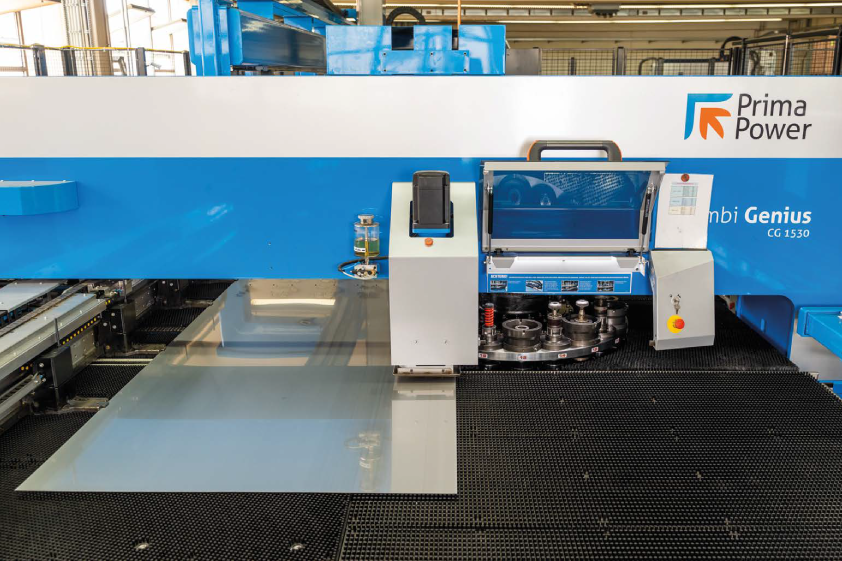

Known for its superior craftsmanship in producing high-quality metal parts, Technoblech has seamlessly transitioned into a beacon of flexible serial production under the visionary guidance of Ron Friedl, its dynamic managing director. The evolution was significantly bolstered by two Prima Power’s Combi Genius systems, marking a pivotal chapter in the company’s journey to become a state-of-the-art manufacturing powerhouse.

CRAFTING PRECISION THROUGH INNOVATION

Since its inception in 1989, Technoblech has carved its niche as a dependable provider of sophisticated metal components, catering to prestigious clients across various sectors, including medical and movie technology, electronics, laboratory and measurement technology as well as mechanical engineering. The company’s commitment to excellence is reflected in its impressive annual production of around 10,000 different products, manufactured in batches of between 1 and 5,000, using a wide range of materials such as steel, aluminum, stainless steel, and copper. The company offers a complete suite of services that includes development, laser cutting and punching, bending, welding, milling to surface finishing.

Extraordinary flexibility and reaction time are among the main strengths of the company: until recently, these were achieved with the commitment of employees and manned working shifts. Ron Friedl’s arrival heralded a new era of efficiency and innovation at Technoblech, with a focused strategy on digitizing and automating manufacturing processes. “I see our further growth potential above all in flexible, costefficient contract manufacturing of larger series and of sample parts,” Friedl remarks.

THE INTEGRATED AUTOMATION ADVANTAGE

Technoblech’s specialty is the processing of sheet metal panels with dimensions of up to 3000 x 1500 mm and with a material thickness of up to 6 mm. Here, the Prima Power Combi Genius CG 1530 with integrated loading and stacking robot LST has been a game-changer for Technoblech, enabling the company to process large sheet metal panels with unmatched efficiency.

“The combined Prima Power punch-laser system Combi Genius 1530, with its fully automated handling configuration, seemed the best and most cost-effective solution. It is a universal talent that allows us to do laser cutting and punching in one operation. The machine allows us to guarantee precise and on-time implementation of all our requirements, no matter how complex,” notes Friedl.

For Ron Friedl, the capacity of the die turret is a real competitive bonus of the machine: in total, up to 384 single or 128 rotating tools can be stored in the punching tool turret with its 16 indexing positions.

The system, featuring a LST robot designed for high-performance loading and stacking, needs minimal human intervention, allowing continuous three-shift operations. This high level of autonomy enhances productivity and significantly reduces production costs and turnaround times.

PRIMA POWER COMBI GENIUS 1530: SOPHISTICATED TECHNOLOGY, SIMPLE PROGRAMMING

While the 4kW fiber laser ensures the high availability of the system with minimal maintenance, the machine features simplify the operation of the laser system and ensure that there is a minimum of manual process interruption. The integration of features like Lens protection glass and the LPM laser plasma monitor bolsters the system’s reliability, minimizing downtime and maintaining consistent quality.

“A decisive advantage of the system is its simple programming. This applies to both operation and programming. My employees got the grips with programming very quickly and, despite the complexity of the system, achieved excellent quality with it right from the start,” Friedl points out.

A touchscreen control panel operates the machine: here, the operator can check machine settings as well as job lists quickly and easily. Four cameras are in the working area to survey the manufacturing process. In addition, a tool management system, among other things, records the number of strokes performed and displays appropriate maintenance information.

“This has significantly reduced our cost per part because the work pieces are produced quickly, easily, and precisely,” adds Friedl.

A VISION OF INNOVATION AND EXCELLENCE

Under Ron Friedl’s leadership, Technoblech has not only preserved its core values of quality and craftsmanship but has also embraced the possibilities of automation, setting a new standard in the sheet metal industry: a shining example of how manufacturing can evolve to meet the demands of modern industry, ensuring that even in the face of rapid technological advancement, the spirit of craftsmanship continues to thrive.

“Our Prima Power machines already operate largely autonomously without any manual intervention. Once the NC programs are properly set up and tested, the machine can run until the stack of sheet metal in the machine is used up, without much monitoring. This, and the combination of multiple operations in one machine, makes the Prima Power machines unbeatable when it comes to versatility and flexibility.” says Ron Friedl.

The combined Prima Power punch-laser system Combi Genius 1530, with its fully automated handling configuration, allows us to do laser cutting and punching in one operation.