Deluxe sheet metal processing

The construction phase of the new Biohort manufacturing site in Herzogsdorf (Upper Austria) lasted just over a year. With cutting-edge industry standards and optimised process cycles, the specialist for storage space solutions created new resources for further growth with new Plant 2, an addition to its Neufelden headquarters.

The result was a 12,000 square metre site that was built using Prima Power's most advanced manufacturing technologies with a view to creating one of the most modern sheet metal processing centres in Europe.

Biohort GmbH, based in Neufelden, Upper Austria, is one of the European market leaders in metal storage solutions. The product portfolio includes high-quality tool sheds, practical storage boxes for outdoor use, and other useful garden additions such as raised beds.

In as early as 1995, Dr. Josef Priglinger was entrusted with managing the production of metal storage sheds in the former standard steel plant located in Niederwaldkirchen. Two years later, he took over 100% of Biohort standard steel shares. Since then, the company has been under the Priglinger family’s control, namely jointly run by father and son - graduate engineer Maximilian Priglinger. “The products which our customers will enjoy for decades are created thanks to sophisticated design, high-quality materials from certified suppliers and Austrian premium processing standards. That is why, in all truthfulness, we grant a 20-year warranty against corrosion,” explains Maximilian Priglinger.

Immersed in greenery

The past two decades have been a true success story for Biohort. 15 to 20% annual growth rates, however, caused the production department in Neufelden to face ever greater challenges, also in terms of manufacturing capacity. To get prepared for the future, in 2016 it was therefore decided to build an additional production plant in the green countryside so as to fully meet production flows.

Biohort invested around 20 million euros in the new location, thus certainly opening another brilliant chapter in the company's success story. The ground-breaking ceremony for the construction of the Herzogsdorf plant took place in July 2017. “Today, we are faced with the results and can rightly state that we own the most modern sheet metal processing plant in Austria,” said Priglinger with justified pride.

Rethinking production processes

“Planning the plant was not just about building a new hall. Manufacturing processes were rethought from start to finish and partly rescheduled. Then the building was built by leveraging on production steps - not the other way around. As a result of the throughput levels implemented, processes are extremely efficient,” reported plant manager Johannes Zauner, a graduate engineer who has headed the project from the beginning.

Last October, the line production was started with Biohort leisure time storage container boxes. The variety of products is planned to be gradually expanded. As a next step, for example, the production of LoungeBoxes, HighBoards, and raised beds will be relocated to Herzogsdorf. “We expect an annual processing volume of around 1,600 tonnes of sheet steel, which corresponds to around 50,000 items,” said Zauner. At the Neufelden site, a total of 7,600 tonnes are processed per year.

With our new production site in Herzogsdorf, we have the most modern sheet metal processing plant in Austria. By selecting Prima Power we are pleased to have chosen a system supplier with whom we were able to successfully handle such a large, challenging project, and who we can continue to rely on in the future.

Eng. Maximilian Priglinger, Managing Director of Biohort GmbH

Impressive networked production technologies

One thing was clear to those responsible from the beginning: to ensure the long-term success of Biohort, the new plant had to rely on innovation and state-of-the-art technology. After intensively comparing suppliers, Prima Power finally came out on top of the list with a completely networked production line consisting of a fully automatic sheet metal warehouse, a punch-shear combination system, and a fully automatic bending machine. “In addition, Prima Power has enabled us to integrate third-party machines into the system as well. For example, our robotic shear feeding system also communicates with the sheet metal warehouse and is supplied with materials,” Zauner explained in a satisfied tone.

Automatic material supply

The production process starts with the automatic storage of raw material into the fully automatic metal warehouse "Night Train Brilliance" by Prima Power. This facility not only ensures optimal storage but is also linked to the manufacturing systems and transfers sheet metal parts according to a predefined manufacturing process. The 50-metre long Night Train has 560 storage box locations (each with a four-tonne capacity) where to store raw materials and finished stamping blanks. If necessary, the sheet metal warehouse in Herzogsdorf can be extended by a further 30 metres.

To punch the required parts, the Shear Genius punch-shear combination system by Prima Power was chosen. “For Biohort products, a punch and shear system is ideal, as most of the manufactured components have a rectangular basic shape. By first punching and then splitting these parts in the same process with an integrated right hand cutting shear, the greatest economic efficiency can be obtained,” emphasised Michael Pröll, Austria Area Manager at Prima Power.

Scratch-free punching and storage

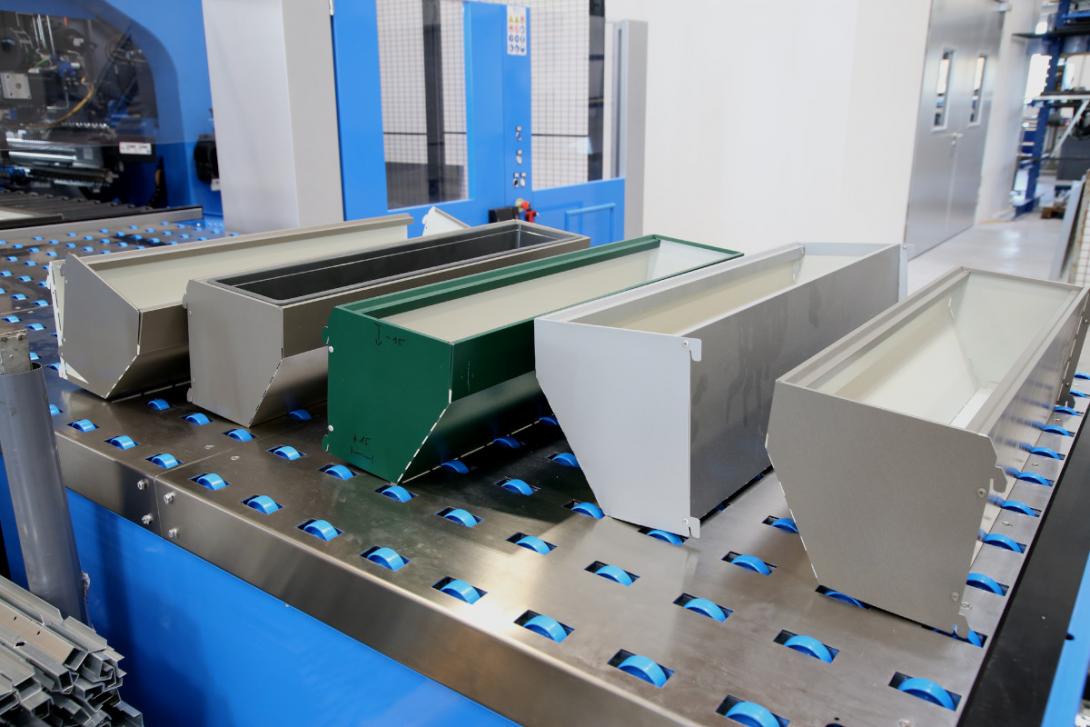

Furthermore, the Sheet Floating System of the machine prevents sensitive surfaces from being scratched. “In this special punching mode, sheets can slide over the raised brush table. We mainly process hot-dip galvanised, polyamide enamelled steel sheets in finished colour and without protective foil. That is why it is especially important for parts to go into production without any scratches,” said Erich Dannerbauer, Deputy Technical Manager at Biohort.

The picking and stacking robot PSR also handles materials extremely gently when unloading the machine. The PSR automates the return of punched parts stacks into the Night Train. “Depending on the part and on the processing steps that are expected to follow, the stacking robot precisely sorts parts into the respective storage boxes, making optimal use of the stacking area,” said Dannerbauer.

Since several punching machines from another manufacturer are in use at Biohort in the main Neufelden plant, Wicam non-proprietary programming software was chosen for punching. “Using a uniform programming system for all punching machines will certainly be a major simplification in the future,” said Dannerbauer putting it straight.

Fully automatic bending

On the other side of the Night Train, next to the raw material storage stations, the robotic shear feeding system and a mechanical press brake, there is EBe 5.3, a fully automatic bending machine by Prima Power. It being, of course, directly connected to the Night Train, the machine is also powered by a PSR picking and stacking robot with already punched plate blanks.

Especially in box manufacturing, as is the case with Biohort, the bending cell can really prove its strengths. “In addition to short set-up times, a big advantage is that you can make any shape - not just simple chamfers, but also, for example, bending radii. And that with only one tool set. In addition, it can be quickly adapted to different product sizes,” said Dannerbauer, impressed by the effectiveness of the EBe machine. Everything has already been prepared also for future products: as for special shapes or, for example, to bend fish plates, non-rotating tools are also available.

Noteworthy are the savings that can be obtained in parts production with respect to conventional mechanical press brakes: “For more complex parts, we are three to four times faster with the bending machine. In this case, no time-consuming tool changeover is required as in the case of mechanical press brakes,” he emphasised. With the new bending solution, great potential is now available that can be used especially for new products. There are interesting new possibilities for product development also in design terms.

Optimised production flow

The absolute highlight of this state-of-the-art sheet metal processing line is, to put it straight, the continuous flow of production which, after goods receipt, is mostly fully automated. The metal sheet is automatically requested by the punch-and-shear combination system and, after being processed by a robot, it is placed on the material box and stored back into the plate blank warehouse as a blank. Thereafter, both the bending machine and the additionally connected shear feeding system will require the necessary parts from the warehouse, which are then automatically prepared.

From there, the finished parts will reach the assembly or packaging lines and then the finished goods warehouse by means of container trolleys. Apart from that, no transport activities such as those performed by a forklift truck will be carried out during the entire manufacturing process. “We can indeed guarantee that materials are brought into production scratch-free, not least because of the low handling effort required for finished components. That was a great challenge for our own high quality standards,” admitted Erich Dannerbauer. And managing director Maximilian Priglinger concluded: “By selecting Prima Power we are pleased to have chosen a system supplier with whom we were able to successfully handle such a large, challenging project, and who we can continue to rely on in the future.”

With our new production site in Herzogsdorf, we have the most modern sheet metal processing plant in Austria. By selecting Prima Power we are pleased to have chosen a system supplier with whom we were able to successfully handle such a large, challenging project, and who we can continue to rely on in the future.

Are you looking for a similar solution for your company? Find it here

Night Train FMS®

ELASTYCZNE SYSTEMY PRODUKCYJNE FMS

Wiodące technologicznie rozwiązanie w zakresie magazynowania w zautomatyzowanych systemach elastycznej produkcji

PSBB

ELASTYCZNE SYSTEMY PRODUKCYJNE FMS

Elastyczny System Produkcyjny FMS

Shear Genius EVO

MASZYNY KOMBI DO WYKRAWANIA I CIĘCIA GILOTYNĄ