Silicon Valley Job Shop Achieves Success with Prima Power Machines

Since A & J Precision Sheetmetal Inc., San Jose, CA, first opened its doors in 1995, the company has earned a stellar reputation as a leading job shop producing high-quality precision parts in the demanding Silicon Valley.

Over the 25 years, A & J has evolved from a one-man shop to a facility of 26,000-square-feet and 60 employees. According to Amrik Atwal, CEO, today A & J has 80 active customers in such industries as semiconductors, networking systems, 3D printing, and medical equipment. Atwal and his wife Jagtar run the company with their son Suki, vp operations. “We have many very smart high-tech customers in the Silicon Valley that keep coming up with new ideas and products,” explains Amrik Atwal. “Our challenge has been to keep up with technology to provide the best quality parts to this market.”

To meet this challenge, A & J has purchased a wide array of fabricating equipment over the years. The company’s relationship with Finn-Power, now Prima Power, goes back to 1995 when the company purchased its first Finn-Power turret punch press, the hydraulic TP2525. This relationship has grown over the years and includes several E5 servo-electric turret punch presses and an E6 Compact Express purchased in 2012. From 2016 to 2018, A & J also purchased three Prima Power eP servo-electric press brakes.

Prima Power eP Press Brakes

The Prima Power eP Press Brake is based on a rigid O-frame. This ensures tool alignment even under stress deformation since there is no horizontal displacement. The position of the upper beam, in relation to the lower beam, is measured by dual Y1 and Y2 linear encoders that are attached independently of the machine frame and are bed referenced. This design isolates ram positioning accuracy from any deflection in the side frames under load and maintains accurate positioning even during off-center bending operations. Ram repeatability on the eP-Series is ± 0.005 mm.

Ease of Programming & Maximum Productivity

An operator-friendly 17” Touch Screen user interface leads to a significant improvement of data input rates and a considerable reduction in programming time. 2D graphical programming with automatic bending sequencing will assist in making even first-time operators productive. The eP Press Brake features the advantages of high acceleration, deceleration, and fast response times of the servo-electric drive system. Compared to conventional brakes, considerable productivity increase can be reached; reduction of cycle times by up to 30% and more is the reality. “These press brakes have reduced our setup times and have dramatically increased accuracy,” says Amrik Atwal.

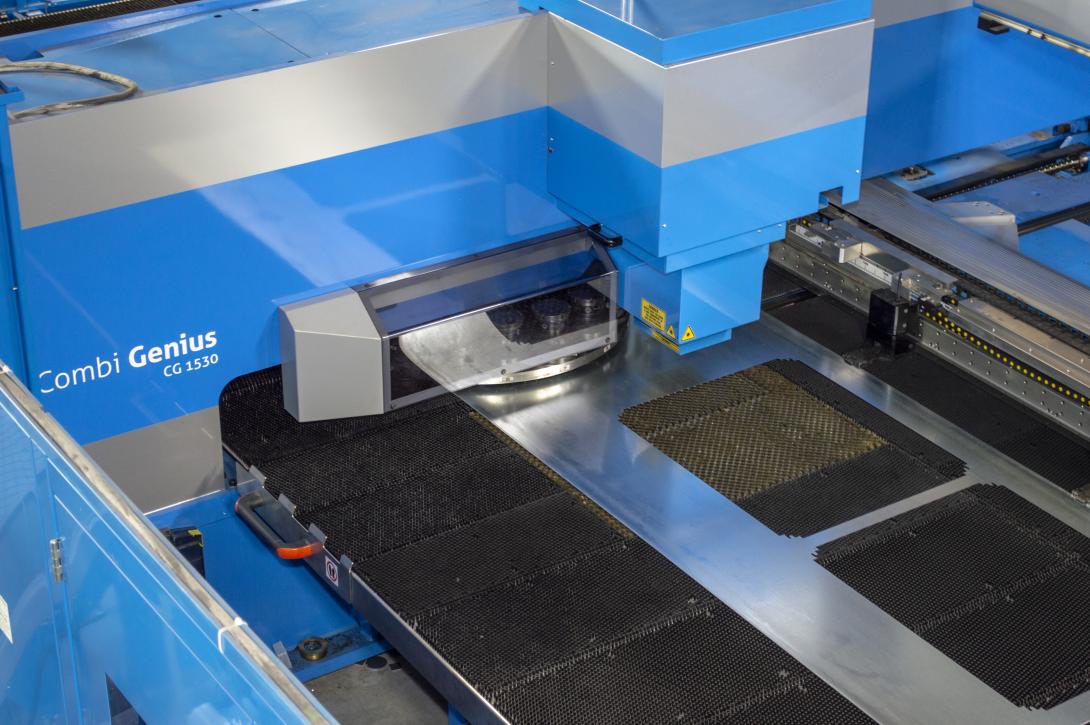

Combi Genius®

Most recently, A & J purchased the Prima Power Combi Genius in 2019. A modern combi machine uses numerically controlled, servo-electric axes, which provides outstanding energy efficiency, low maintenance requirement and a high speed of operation. The cornerstones of its productivity include large tool capacity, the wide range of tools available and easy and fast set-up change. As the best laser power source for the combi machine, the genuine fiber laser has very high efficiency. Its highest utilization degree is conveniently suitable for material thicknesses less than 8 mm. Forming and other auxiliary work stages and ease of use are additional factors reducing the manufacturing cost per component, thus making the Combi Genius machine a productive and competitive manufacturing solution.

State-of-the Art Fiber Laser Cutting

Combi Genius combines the benefits of this punching performance with the latest in fiber laser cutting, raising the productivity of the highly versatile integrated manufacturing concept to a new level. As the laser source, a fiber resonator of either 3 kW or 4 kW can be chosen. The optimized cutting head, collimator, transfer fiber and cutting parameters ensure a very high cutting quality and speed. An easy cover protection system around the machine is especially designed for the requirements of the combi machine. This provides protection from any scattered radiation of the fiber laser, but allows loading, unloading and maintenance procedures for the operator as easily as possible.

No Setups

The unbeatable tooling concept by Prima Power is a time saver – no extra stops for tool changes, no setups – all tools are active for immediate use.

• Customizable turrets

• Compatible with different tool manufacturers

• Multi-Tools®

• Index tools

• Intelligent ram

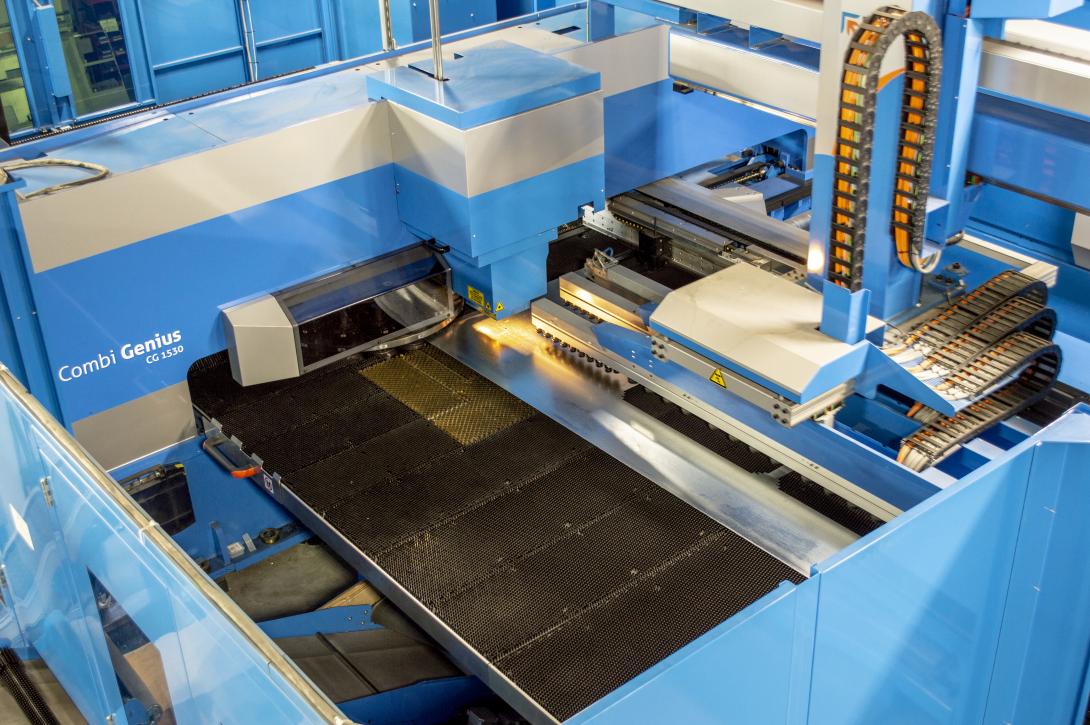

“We discussed purchasing a combi machine for a number of years,” explains Suki Atwal. “We had a couple of jobs that we were running on the turret punch press, and the secondary operations were very time consuming that slowed down the entire process. These large parts were heavy material and our operators were breaking out parts. By the time the machine would run one sheet it would take the people the same amount of time to shake out the parts, deburr them, and prepare them for the next operation. So that was what started the conversation. I began the research and we started looking into other process options.”

A & J chose the Prima Power Combi Genius that was installed in 2019. “Currently, we have two different customers that have high-volume jobs,” continues Suki Atwal. “We use the Combi Genius on unique jobs that also have odd contours and a lot tapping requirements. There are parts that we do on it today that we could not have do before purchasing the Combi Genius.

“We run the Combi Genius 24/7,” adds Amrik Atwal. “During the night and weekends, it runs lights out. We have one job that has three different size taps that we can do very efficiently on the Combi Genius. Previously, we had to do two of the taps by hand...this was very time consuming. It would take 24-30 hours to complete the job. With the Combi Genius it now takes only eight hours. We have the capability of six different sized taps on the Combi Genius. Our quality has also improved. Before we were just punching. Today, with the laser cutting on the Combi Genius there are no micro joints to clean up.”

Another feature that A & J likes about the Combi Genius is the automatic loading and part stacking. The LST is a compact high-performance automatic loading and stacking robot. The LST loads the sheets into the machine, picks the parts and sorts them to stacks to be used in the following process steps. The entire working cycle of the machine is automatic. “The stacking has been a great help,” says Suki Atwal. The LST allows our operators to use larger-sized sheets more safely and efficiently.”

Bottom Line

“We estimate that our ROI on the Combi Genius is 18-24 months,” concludes Suki Atwal. “There are a number of new jobs where the Combi Genius has cut our lead time in half. We are sending these parts to Mexico for assembly. We see another Combi Genius in our future. Over the years, we have been able to grow because we’ve had the right people and the right equipment. We have grown along with the different generations of Prima Power equipment. Every time Prima Power introduced new technology, we realized that it would be beneficial to many of our customers. For the past five years we have purchased a new Prima Power machine each year. Why? Because they do what they are supposed to do -- produce cost efficient, high-quality parts.”

We run the Combi Genius 24/7, during the night and weekends, it runs lights out. We estimate that our ROI on the Combi Genius is 18-24 months, there are a number of new jobs where the Combi Genius has cut our lead time in half. We see another Combi Genius in our future.

Are you looking for a similar solution for your company? Find it here

Combi Genius

MÁQUINAS COMBINADAS DE PERFURAÇÃO E CORTE A LASER